Floating oil return mechanism

A technology of oil return pipe and oil return flange, which is applied in the field of floating oil return mechanism, can solve the problems of poor oil return, flattened hose, and affecting lubrication effect, etc., and achieves the effect of convenient maintenance and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

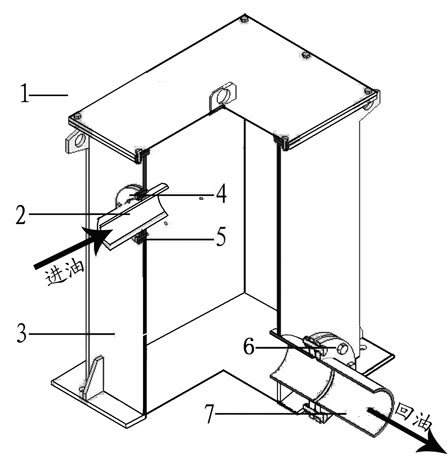

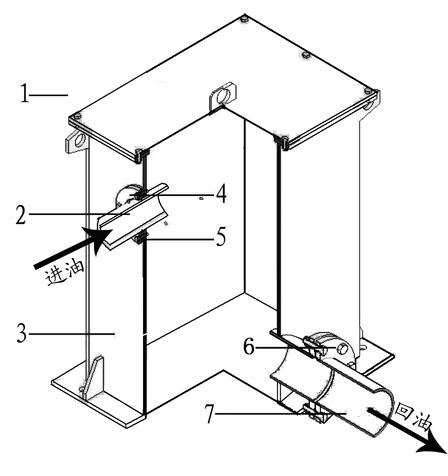

[0011] Such as figure 1 As shown, it includes a sealing box body 3, a box cover 1, an oil inlet flange 4, a rubber gasket 5, an oil inlet pipe 2, an oil return flange 6 and an oil return pipe 7. The sealing box body 3 is a welded structural part fixed on On the basis; the tank cover 1 is a welded cover plate with a handle for easy cleaning and installation adjustment; the oil inlet flange 4 is fixed on the upper side of the sealed box body 3 to guide the oil inlet pipe 2; the oil inlet pipe 2 and The body of the uncoiler is rigidly connected, and rubber gaskets 5 are installed between the oil inlet flanges 4 to prevent external debris from contaminating the lubricating oil and oil leakage; the oil return flange 6 is fixed directly below the sealing box 3, and the oil return flange 6 Connect the oil return pipe 7 to ensure that the oil return pipe 7 is unimpeded, and the oil return pipe 7 is connected to the oil tank of the thin oil lubrication station through the intermediate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com