Numerically-controlled machine tool gearbox intelligent oil return system with auxiliary oil tank and working method of numerically-controlled machine tool gearbox intelligent oil return system

A technology of oil return system and CNC machine tool, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., and can solve the problem of inability to adjust the opening and closing time of the oil pump, not mentioning the on-off of the oil return circuit, and reducing the effect of lubrication and cooling and other problems to achieve the effect of avoiding continuous non-stop work, reducing energy consumption and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

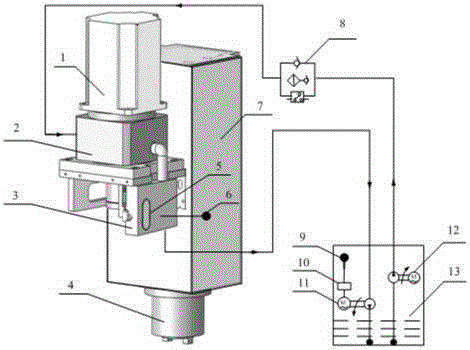

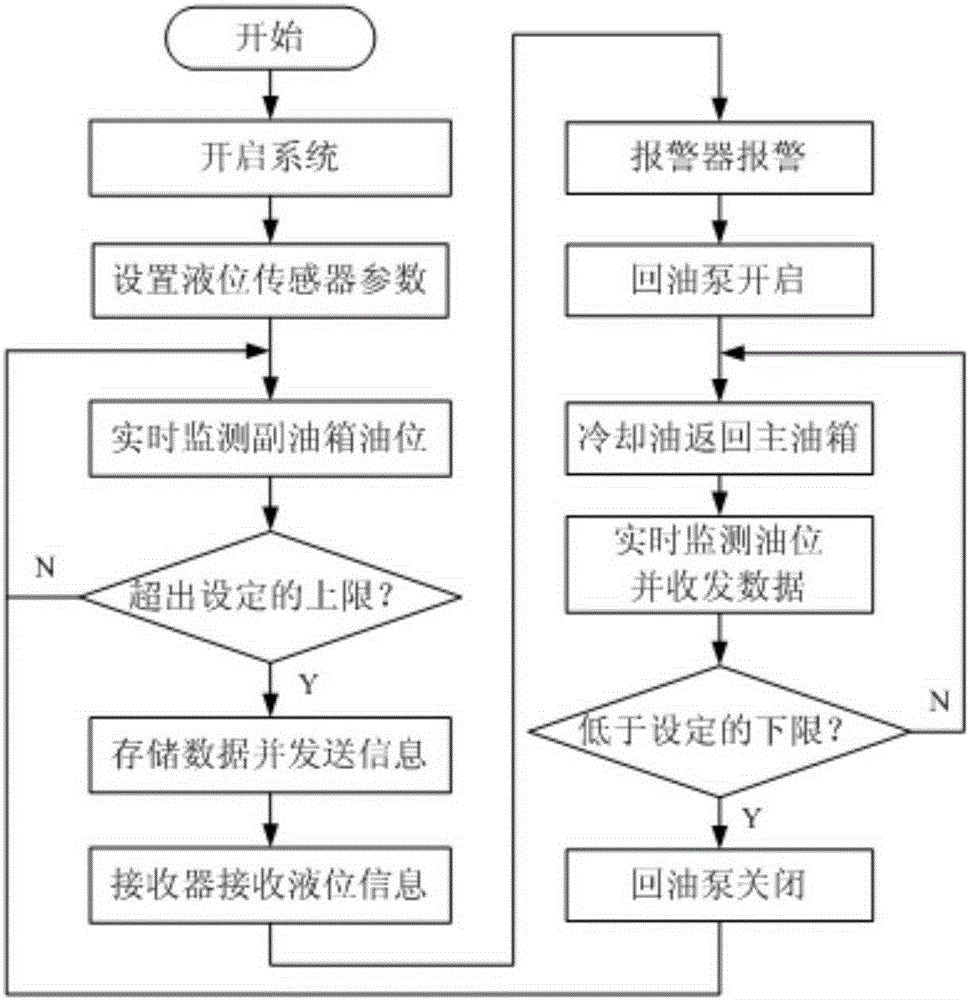

[0030] like figure 1 As shown, an intelligent oil return system for a CNC machine tool gearbox with an auxiliary oil tank includes a motor 1, a gearbox 2, an auxiliary oil tank 3, a main shaft 4, a liquid level sensor 5, a transmitter 6, a filter 7, an information receiver 8, Relay 9, oil return pump 10, oil well pump 11 and main oil tank 12.

[0031] The motor 1 is installed on the upper end of the gear box 2 , the gear box 2 is connected and installed with the ram 7 , and the motor 1 drives the main shaft 4 through the gear transmission in the gear box 2 .

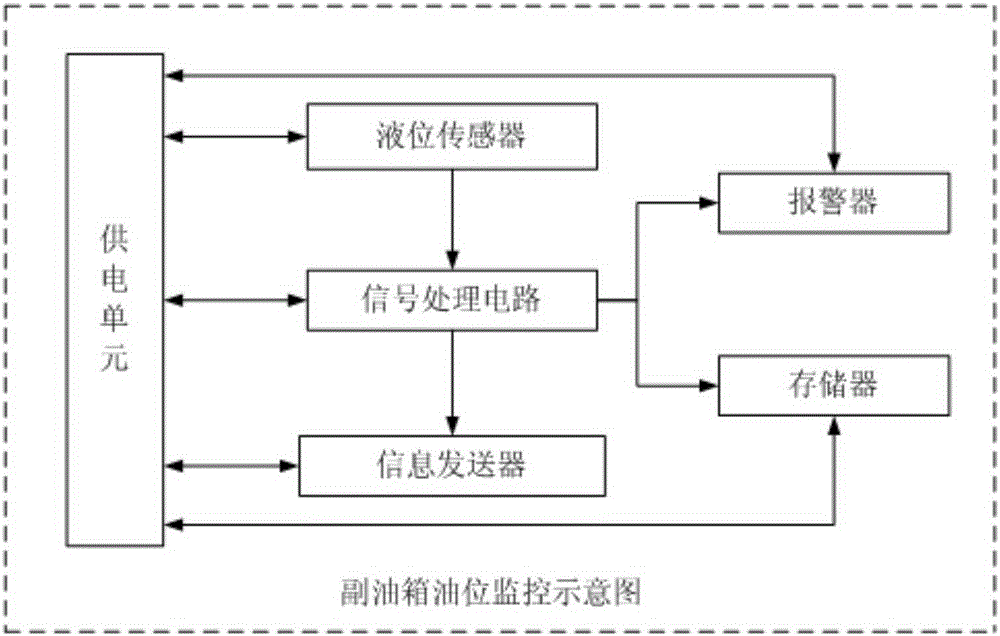

[0032] The auxiliary oil tank 3 is installed below one side of the gear box 2, and its oil inlet hole is connected with the gear box 2 through a short oil pipe, and the cooling oil in the gear box 2 can automatically flow into the auxiliary oil tank 3, and the oil outlet hole passes through the oil return pump 10 Connected to the main oil tank 12, a liquid level sensor 5 is installed in the auxiliary oil tank 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com