Device for testing input speed of aeroengine centrifugal sensor

A technology of aero-engine and input speed, which is applied in measurement devices, linear/angular velocity measurement, devices using electric/magnetic methods, etc. Improve the accuracy of detection and data, simple structure, real and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

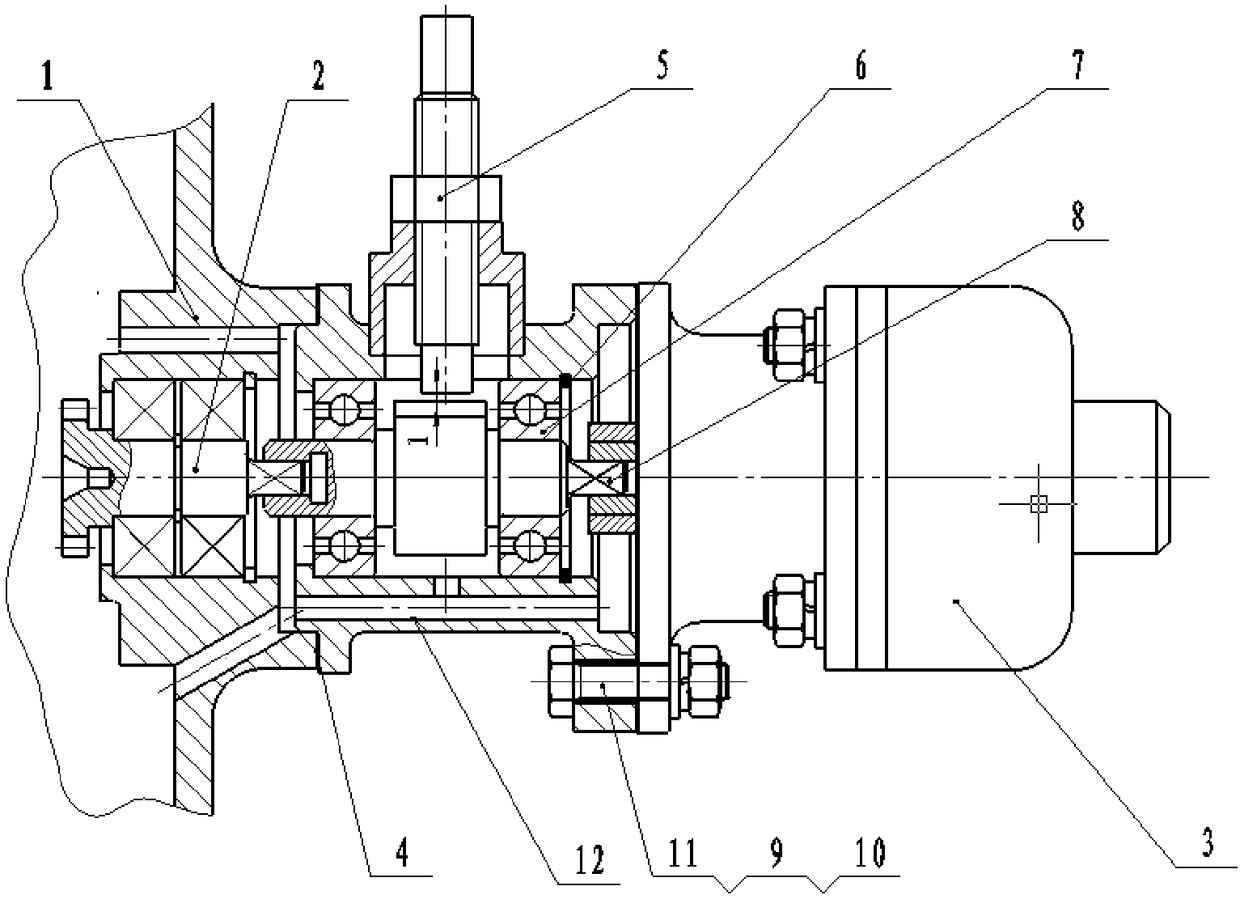

[0032] The present invention is described in further detail below in conjunction with accompanying drawing:

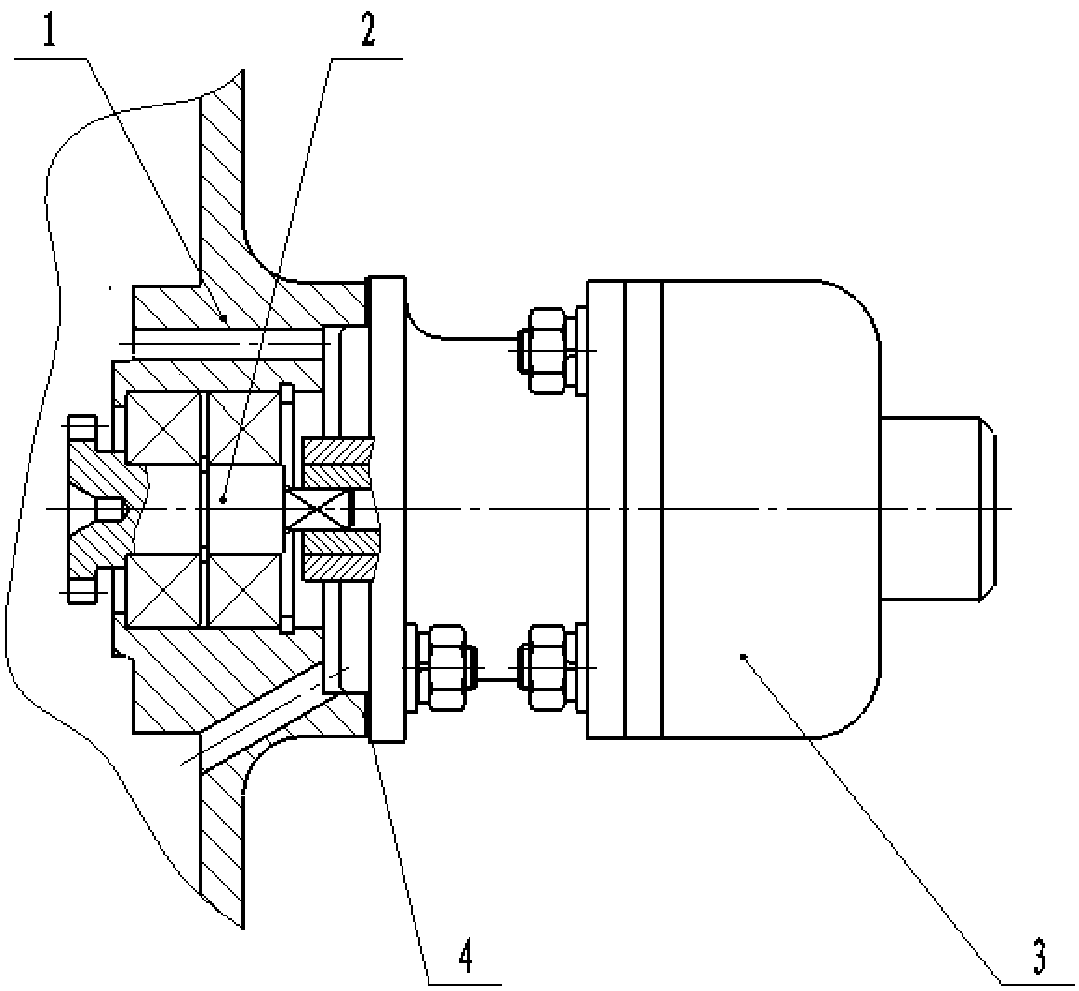

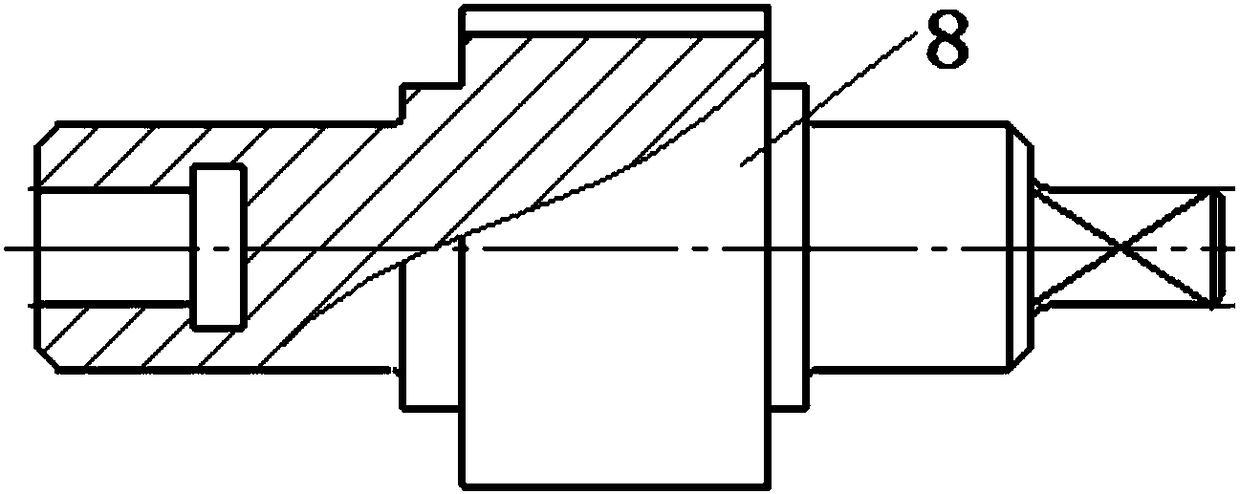

[0033] like figure 2 As shown, an aeroengine centrifugal sensor input rotational speed test device includes an adapter seat 12 connected between the engine case 1 and the centrifugal sensor 3, one end of the adapter seat 12 is press-fitted into the engine case 1, A sealing gasket 4 is provided between the adapter seat 12 and the attached casing 1, and the other end of the adapter seat 12 is connected with the centrifugal sensor 3 through bolts 9 and nuts 11, and a washer 10 is arranged on the bolts 9 and nuts 11. The seat 12 is a middle-pass structure, the adapter seat 12 is provided with a counting gear shaft 8, the middle of the counting gear shaft 8 is a counting tooth, one end of the counting gear shaft 8 is connected to the input shaft of the centrifugal sensor 3, and the other end of the counting gear shaft 8 is connected to the hair attached The driven gear sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com