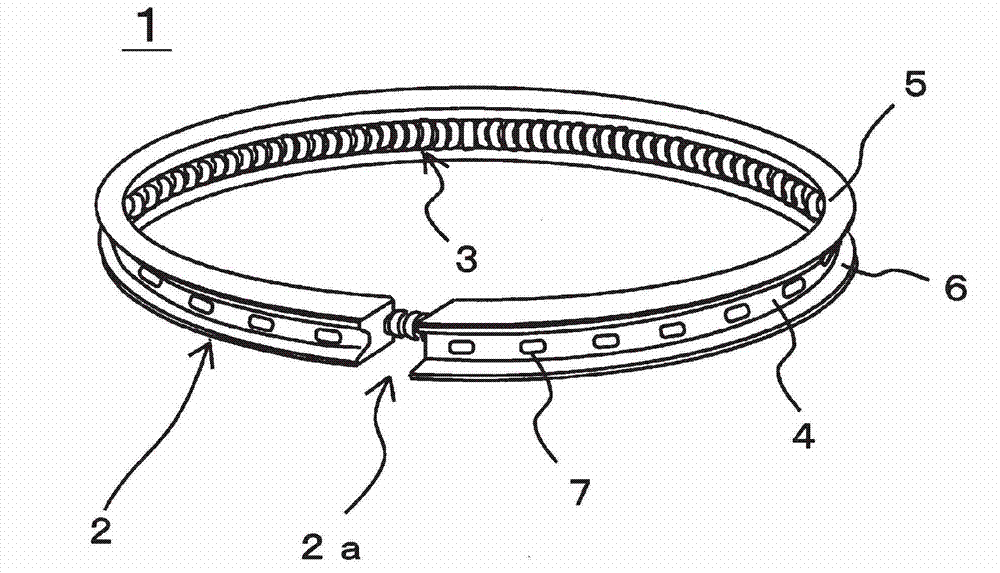

Oil ring for internal combustion engine

A technology for internal combustion engines and oil rings, applied to piston rings, mechanical equipment, engine components, etc., can solve the problems of reduced strength of the main body of the oil ring, hindering the detachment of engine oil, blocking the oil return hole, etc., and achieve the effect of fuel consumption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

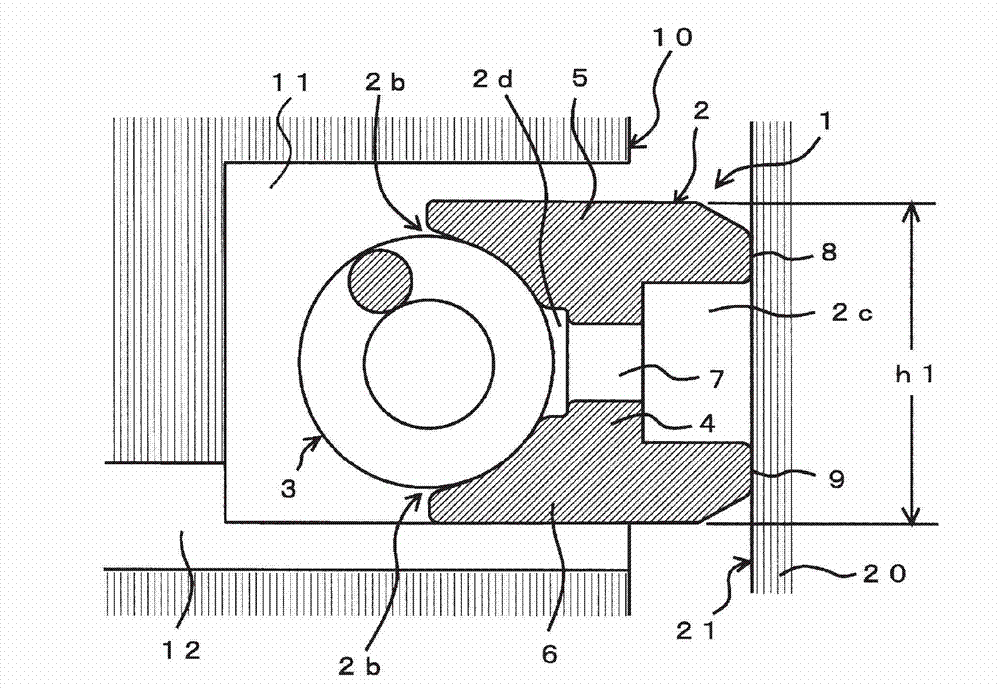

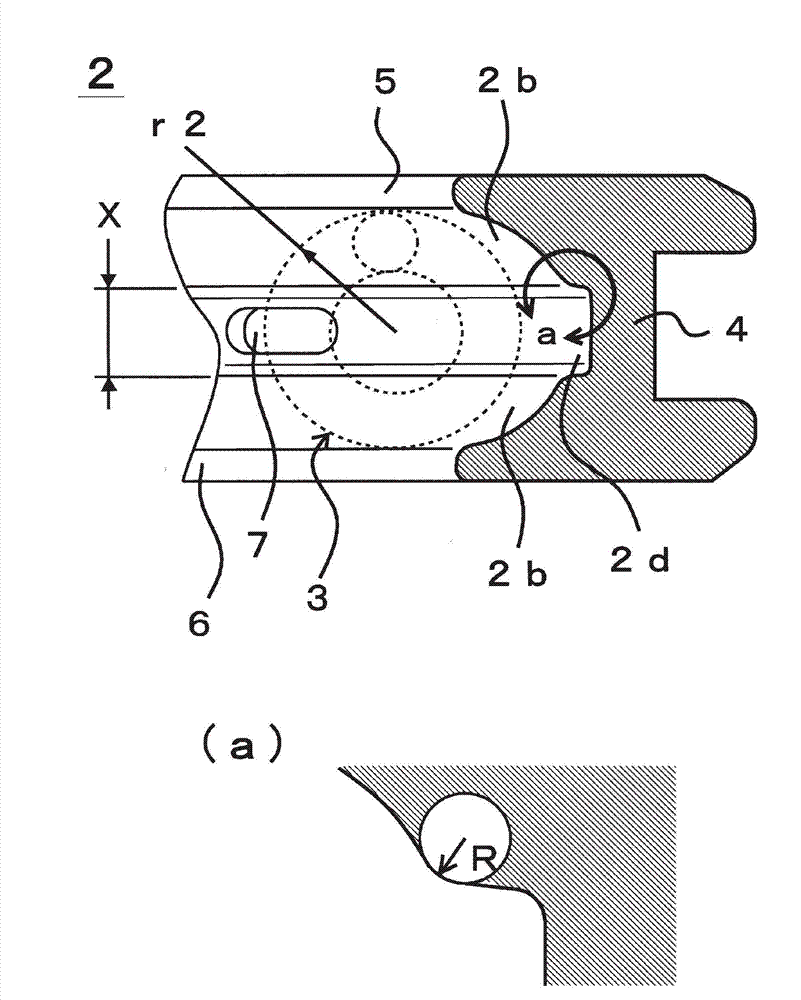

[0099] In Example 1, the actual machine test of a four-cylinder gasoline engine with a displacement of 2000 cc and a cylinder bore of 86 mm was carried out, and it was confirmed that the inner peripheral surface of the coil spring accommodation recess of the oil ring has an oil return groove and the engine without an oil return groove. The engine of the oil tank, whether there is a difference in fuel consumption. And, the operation condition of the engine was 5000 rpm at full load (WOT) for ten hours. Furthermore, the combination of piston rings is a top ring, a second ring, and an oil ring. As the top ring at this time, a ring made of 10Cr steel having an axial width (h1) of 1.2 mm and a radial width (a1) of 2.9 mm was subjected to gas nitriding treatment. The second ring is a ring made of FC material with an axial width (h1) of 1.2 mm and a radial width (a1) of 3.4 mm.

[0100] In addition, for the sake of caution, the 10Cr steel constituting the top ring and the FC materi...

Embodiment 2

[0113] In Example 2, an actual machine test of a four-cylinder gasoline engine with a displacement of 1500 cc and a cylinder bore of 73 mm was carried out, and it was confirmed that the engine with an oil return groove on the inner peripheral surface of the coil spring accommodation recess of the oil ring and the engine without an oil return groove The engine, does it differ in fuel consumption. In addition, in Example 2, the engine was driven under the same driving conditions as in Example 1, and it was confirmed how the difference in the shape of the oil ring body used would affect the characteristics (fuel consumption performance) of the oil ring. Furthermore, similarly to Example 1, the piston ring used consisted of a top ring, a second ring, and an oil ring. As in Example 1, as the top ring at this time, a ring made of 10Cr steel with an axial width (h1) of 1.2 mm and a radial width (a1) of 2.9 mm was subjected to gas nitriding treatment. As in Example 1, a ring having a...

Embodiment 3

[0123] In Example 3, the same engine as in Example 2 was used. In addition, the engine was driven under the same driving conditions as in Example 2, and it was confirmed that the difference in the shape of the oil ring body used would affect the characteristics of the oil ring (fuel consumption Quantitative performance) what impact. Furthermore, similarly to Example 1 and Example 2, the piston ring used consisted of a top ring, a second ring, and an oil ring. As in Example 1 and Example 2, the top ring at this time is gas nitriding treatment of a ring made of 10Cr steel with an axial width (h1) of 1.2 mm and a radial width (a1) of 2.9 mm. ring. Similar to Example 1 and Example 2, a ring made of FC material with an axial width (h1) of 1.2 mm and a radial width (a1) of 3.4 mm was used as the second ring. In addition, as in the first and second embodiments, the oil ring of the third embodiment uses a two-piece oil ring for an internal combustion engine. As in Examples 1 and 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com