Oil returning gas removal device and lubricating oil system

A gas device and lubricating oil technology, applied in lubricating oil containers, lubricating parts, engine lubrication, etc., can solve the problems of reduced lubricating oil transportation capacity, high bearing bush temperature, abnormal vibration and noise of the system, etc., to avoid oil return and rolling , Guarantee the effect of lubrication, reduce the effect of cavitation noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

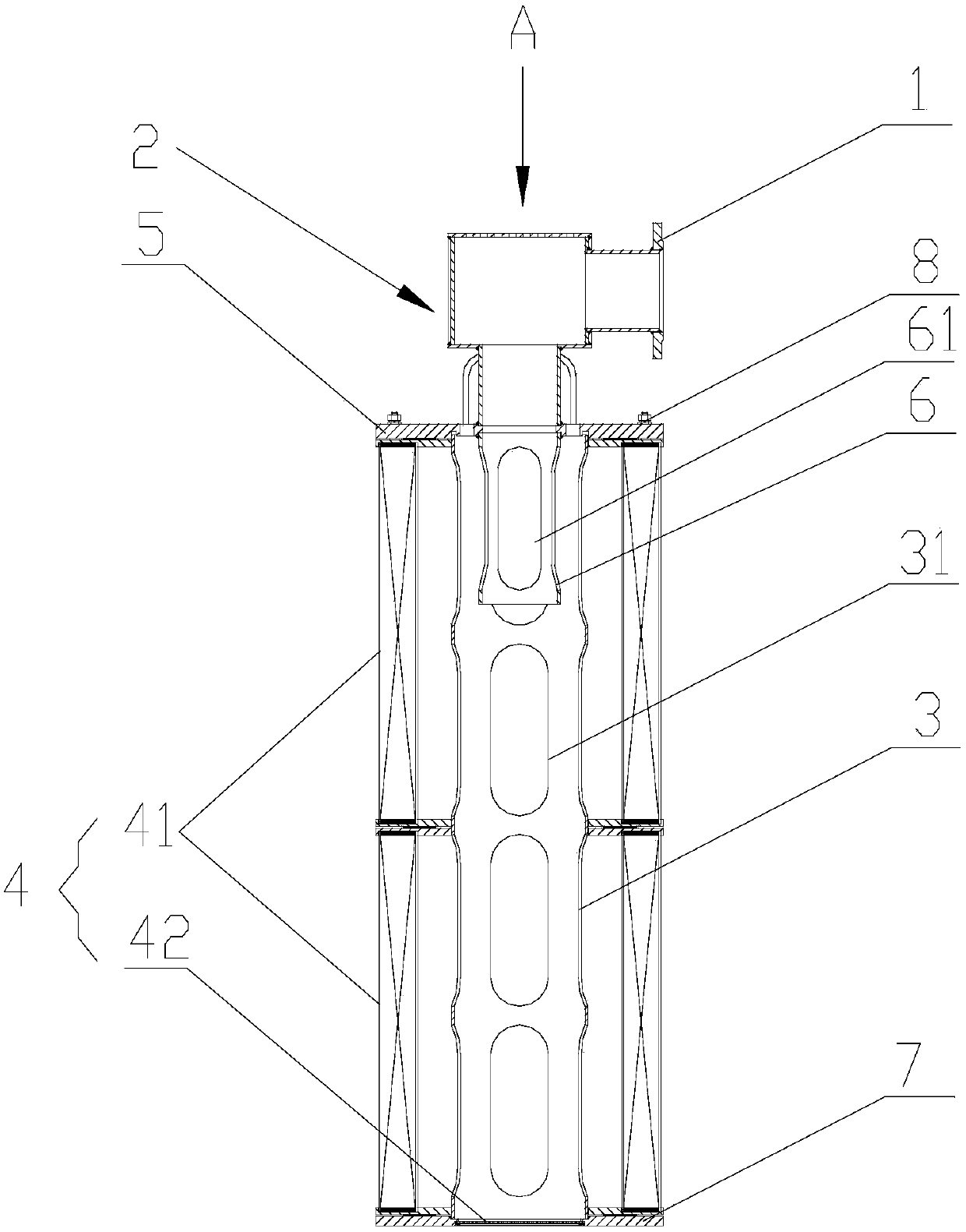

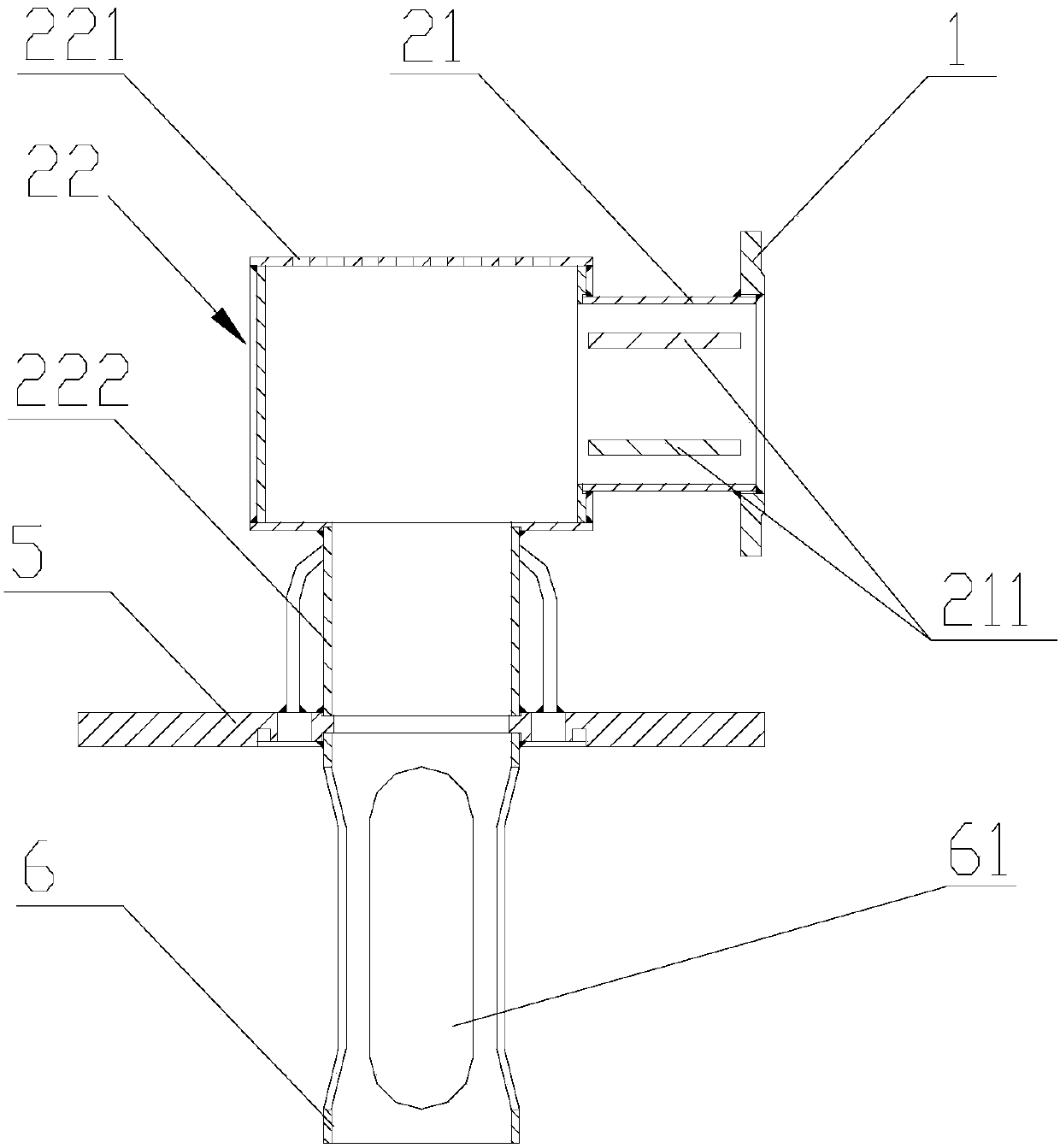

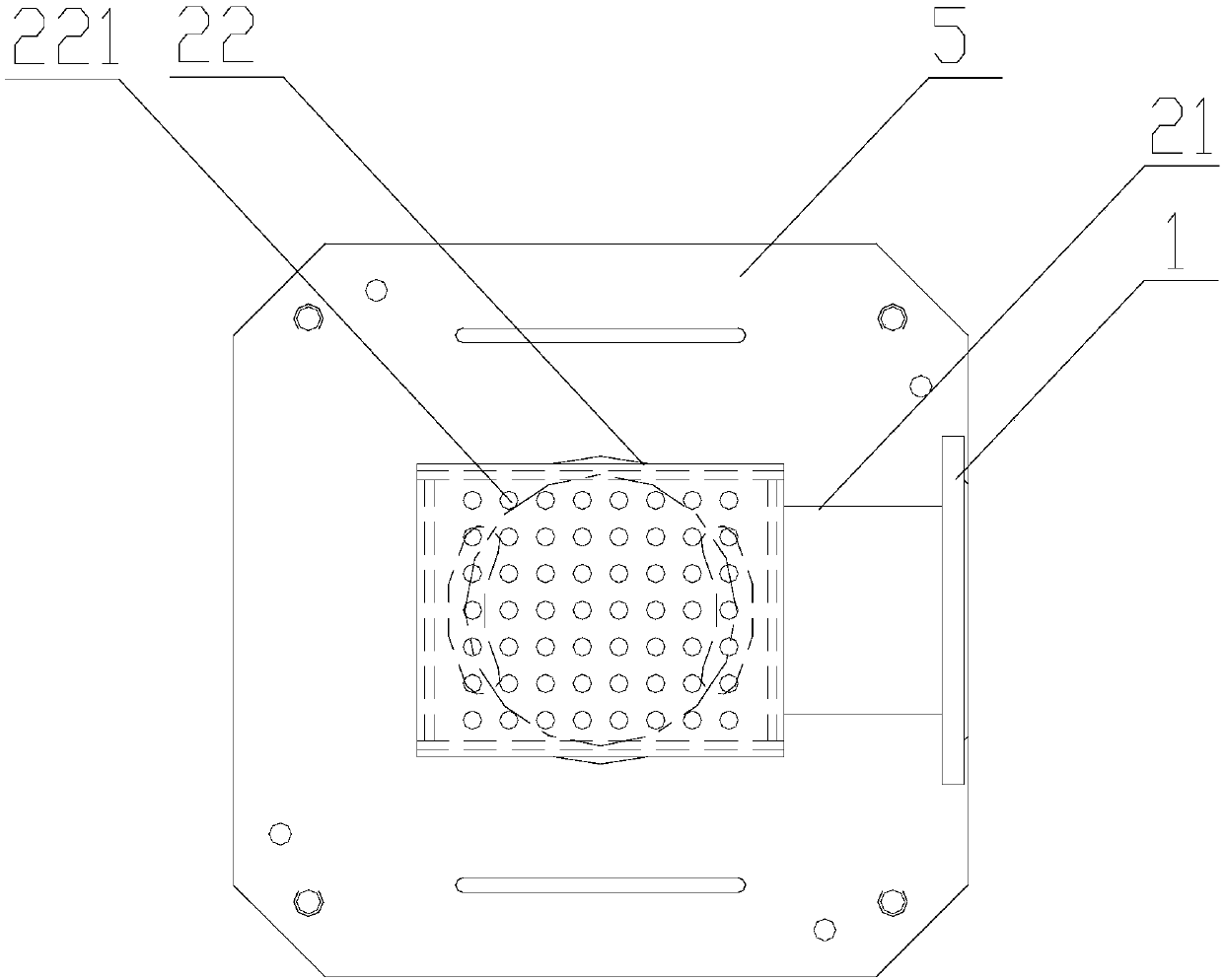

[0033] see figure 1 As shown, the embodiment of the present invention provides an oil return and degassing device, which is arranged in an oil tank of a lubricating oil system. The connecting piece 1 is used to install the oil return and degassing device to the oil return hole on the inner wall of the oil tank, and the connecting piece 1 can be a flange plate, and the flange plate is matched with the oil return hole. The inlet end of the oil return pipe assembly 2 is connected to the connector 1, the sleeve 3 is arranged at the outlet end of the oil return pipe assembly 2, and forms a continuous pipeline with the oil return pipe assembly 2, and a plurality of oil passage holes are opened around the cylinder wall of the sleeve 3 31. The oil passage holes 31 are arranged at intervals along the length direction and the circumferential dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com