Aluminum honeycomb type evaporation plate and processing molding method thereof

A technology for processing and forming aluminum alloy plates, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problem of aluminum alloy profile wall thickness, complex structural forming, unstable quality of aluminum alloy evaporation plates, and heat exchange of evaporation plates. Efficiency is not too high, to achieve the effect of not easily forming dead ends, preventing deformation and warping, and improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

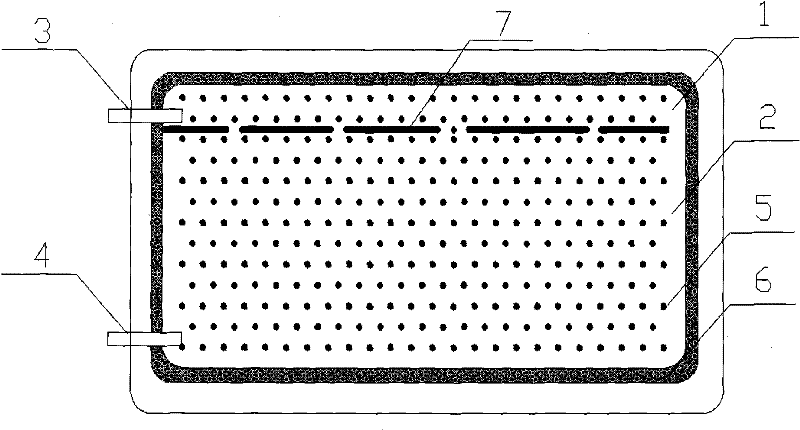

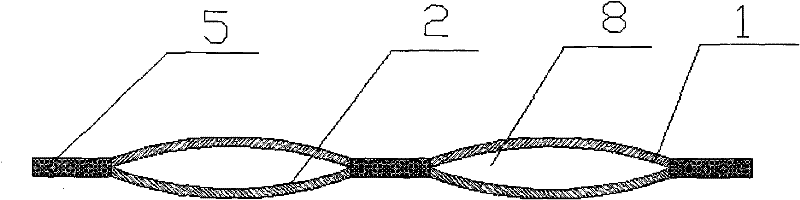

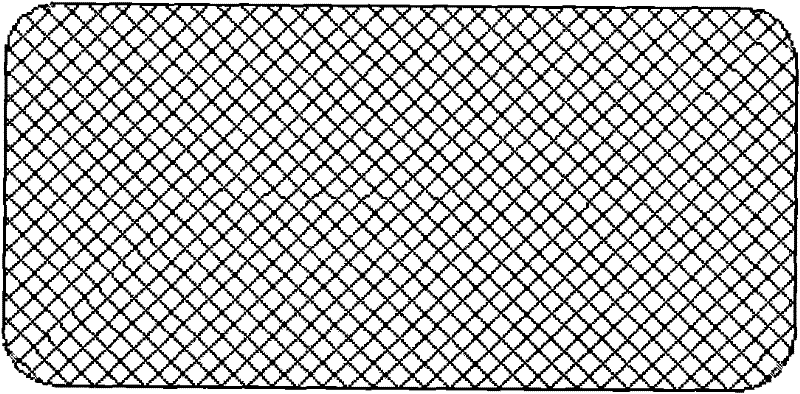

[0052] see figure 1 or figure 2 or image 3 , two 6063 aluminum alloy plates with a length of 1.5m, a width of 0.8m, and a thickness of 1.8mm are processed and processed. Rolling to form micro-patterns on the surface, adopting the method of friction stir welding, welding two aluminum alloy plates with a welding process of 800r / min and welding speed of 150mm / min to form honeycomb solder joints with a total of 880 equidistant points. The length of 4 isolation welds is 1300mm, and the surroundings are sealed and welded together; the aluminum-copper composite inlet pipe and the aluminum-copper composite outlet pipe are sealed and connected with the aluminum alloy evaporation plate body by arc welding; the inflation positioning mold is used, and the high-pressure gas The aluminum alloy evaporating plate is bulged to form a honeycomb evaporating plate with hollow channels and dimple-like corrugations on the surface; then perform other post-welding processes and apply pressure, su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com