Process for producing environment-friendly aromatic rubber oil

A high-aromatic and rubber oil technology, which is only applied in the direction of multi-stage serial refining process, can solve the problems of increased carcinogenicity and reduced viscosity of extender oils

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

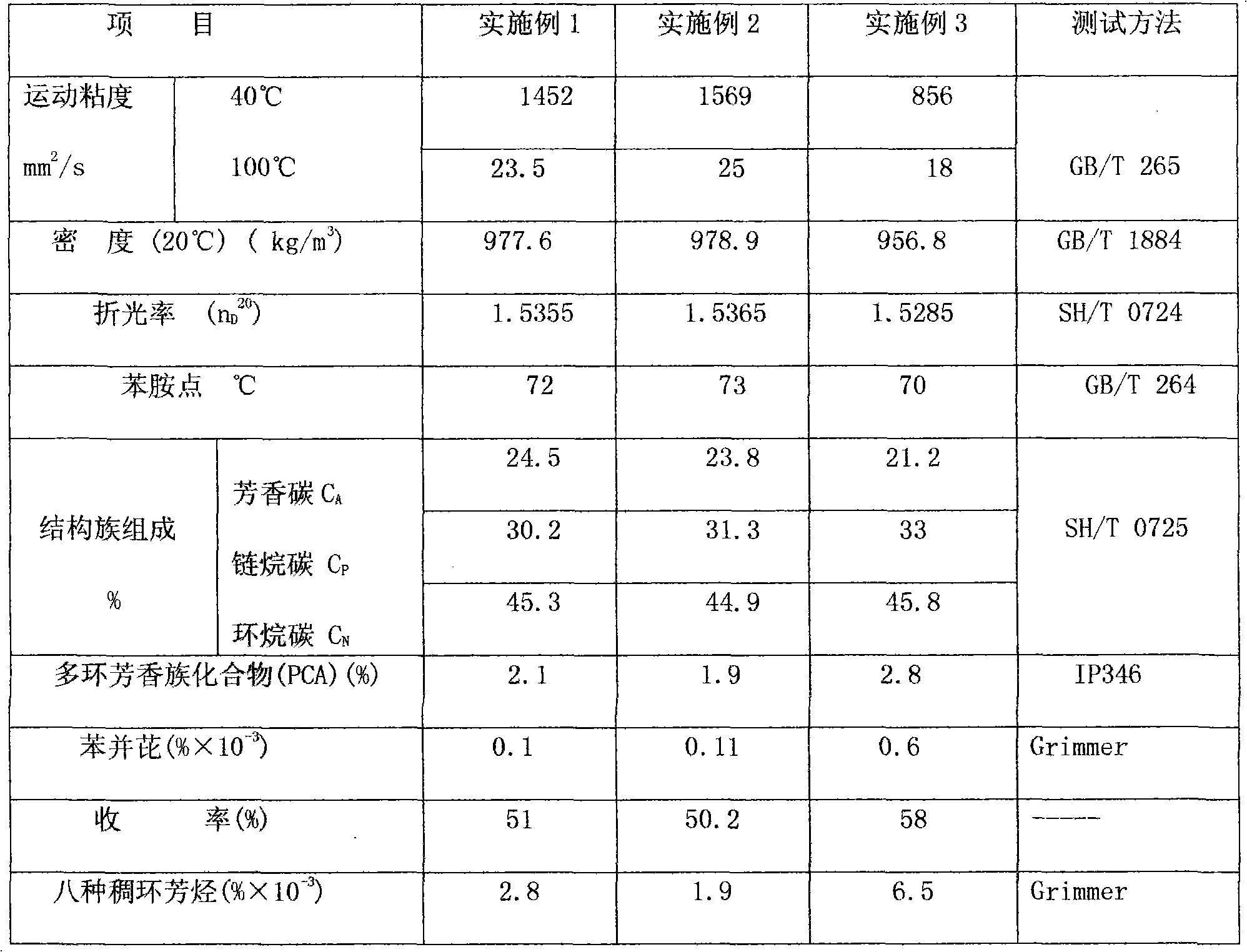

Embodiment 1

[0014] The preparation of embodiment 1 environmental protection high aromatic hydrocarbon rubber oil

[0015] The preparation of environment-friendly aromatic hydrocarbon oil comprises the following steps:

[0016] 1) Take the extracted oil (China Petroleum Liaohe Lubricating Oil Factory) as the raw material and dilute it with cyclohexane. The dilution process needs to be fully stirred until the raw material is completely dissolved, and there is no specific requirement for the dissolution temperature. The selected solvent cyclohexane The mass ratio of the extracted oil to minus three is 0.2:1.

[0017] 2) Primary extraction. Add dimethyl sulfoxide to the above diluent oil for primary extraction. The extraction temperature is 100--110°C. The stirring time is 1 hour. The mass ratio of diluent oil to solvent dimethyl sulfoxide The ratio is 1:2. After standing for 4 hours, it is separated. The lower dimethyl sulfoxide layer after separation is the extract, and the upper layer is ...

Embodiment 2

[0021] The preparation of embodiment 2 environmental protection high aromatic rubber oil

[0022] The preparation of environment-friendly aromatic hydrocarbon oil comprises the following steps:

[0023] 1) Take the extracted oil (China Petroleum Liaohe Lubricating Oil Factory) as the raw material, and dilute with petroleum ether as the solvent. The dilution process needs to be fully stirred until the raw material is completely dissolved, and there is no specific requirement for the dissolution temperature. The selected solvent petroleum ether and the reduced The mass ratio of the three extracted oils is 0.3:1.

[0024] 2) Primary extraction. Add dimethyl sulfoxide to the above diluent oil for primary extraction. The extraction temperature is 100-110°C. The stirring time is 1 hour. The mass ratio of diluent oil to solvent dimethyl sulfoxide is 1:2. Separation after standing for 4 hours. After separation, the lower layer of dimethyl sulfoxide is the extract, and the upper layer...

Embodiment 3

[0028] The preparation of embodiment 3 environmental protection high aromatic hydrocarbon rubber oil

[0029] The preparation of environment-friendly aromatic hydrocarbon oil comprises the following steps:

[0030] 1) Take the extracted oil (PetroChina Liaohe Lubricating Oil Factory) as the raw material, and dilute it with HVI150 (Yanshan Petrochemical) as the solvent. The dilution process needs to be fully stirred until the raw material is completely dissolved, and there is no specific requirement for the dissolution temperature. The selected solvent ring The mass ratio of hexane to the extracted oil is 0.1:1.

[0031] 2) Primary extraction. Add dimethyl sulfoxide to the above diluent oil for primary extraction. The extraction temperature is 100-110°C. The stirring time is 1 hour. The mass ratio of diluent oil to solvent dimethyl sulfoxide is 1:2. Separation after standing for 4 hours. After separation, the lower layer of dimethyl sulfoxide is the extract, and the upper laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com