Oil way structure of transformer

A technology of transformer and oil circuit, applied in transformer/inductor cooling, transformer/inductor components, transformer/inductor coil/winding/connection, etc., can solve the problem of oil temperature rise, affecting the heat dissipation and insulation of the upper wire cake problems such as life and operation safety, to achieve the effect of saving costs, improving heat dissipation, and being easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

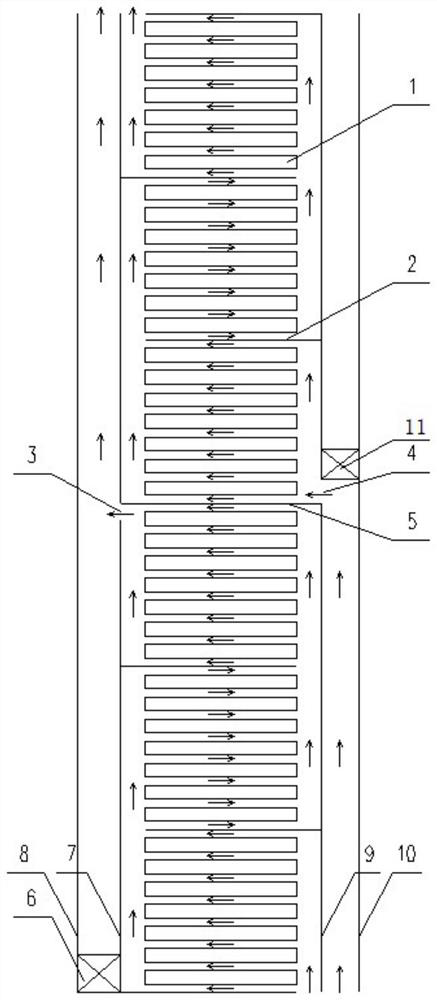

[0019] Such as figure 1 As shown, a transformer oil circuit structure, including coils and wire cakes 1, several coils and wire cakes 1 are arranged sequentially from top to bottom, and oil baffle plates are arranged between several coils and wire cakes 1 2. The oil baffles 2 are arranged alternately on the left and right, so that an S-shaped oil passage is formed on the coil and the wire cake 1. The first oil passage and the second oil passage are arranged on the inner side of the coil and the wire cake 1, and the outer sides of the coil and the wire cake 1 are sequentially arranged. Set the third oil passage and the fourth oil passage, the first oil passage is divided into the lower first oil passage and the upper first oil passage, the lower first oil passage and the upper first oil passage are not connected to each other, the third oil passage is divided into The lower third oil passage and the upper third oil passage, the lower third oil passage and the upper third oil pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com