Hub reduction gear combined sealing structure

A wheel-side reducer and combined sealing technology, applied in the field of vehicle transmission, can solve problems such as easy oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

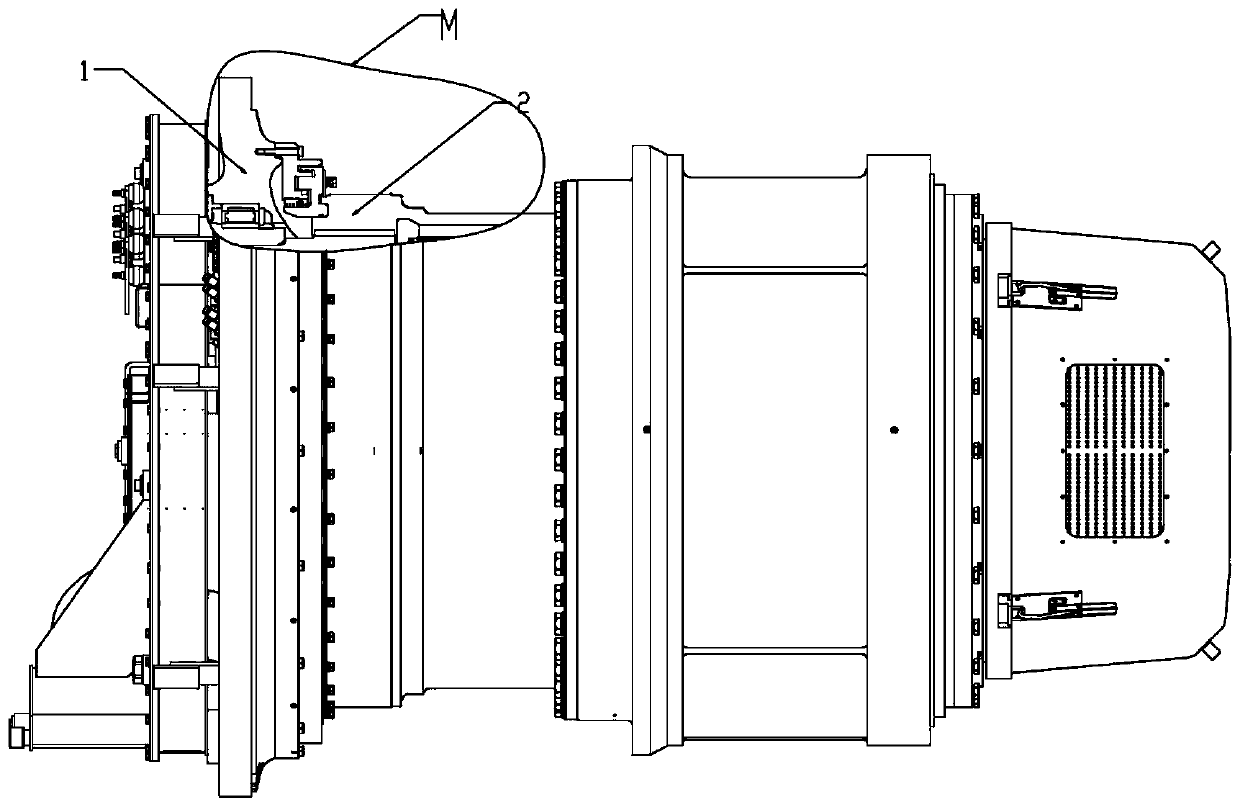

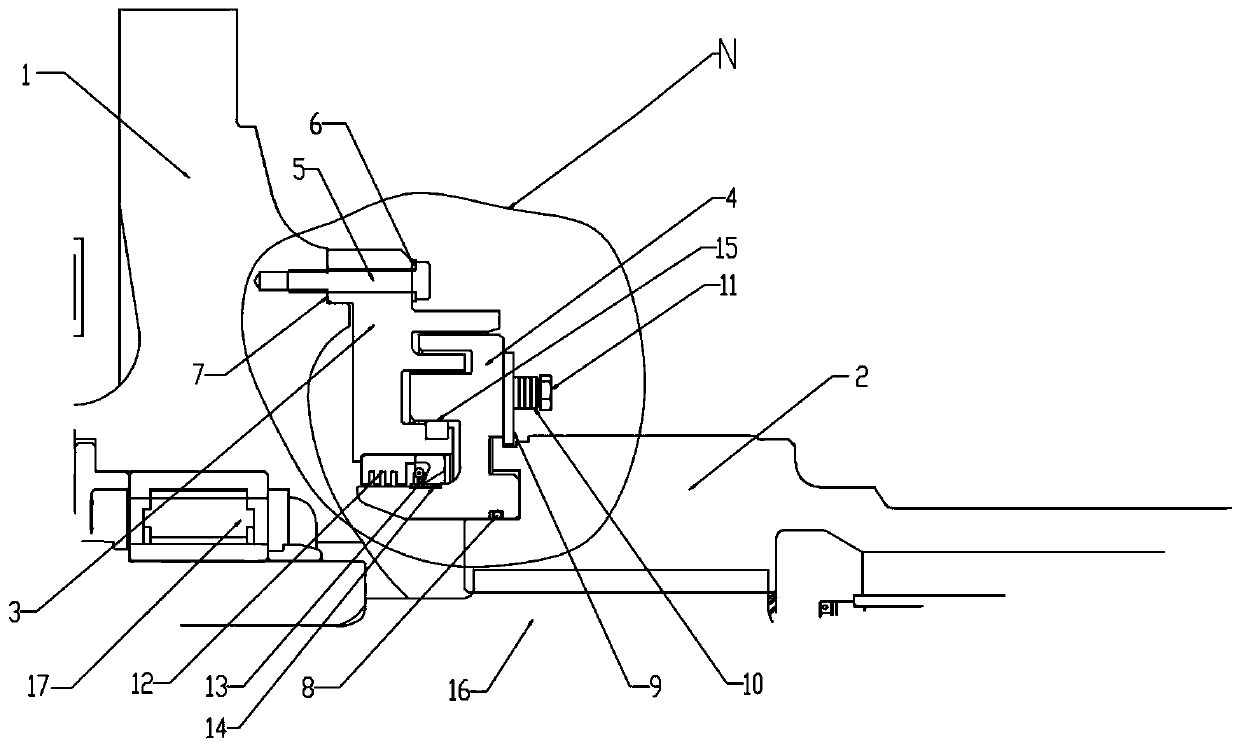

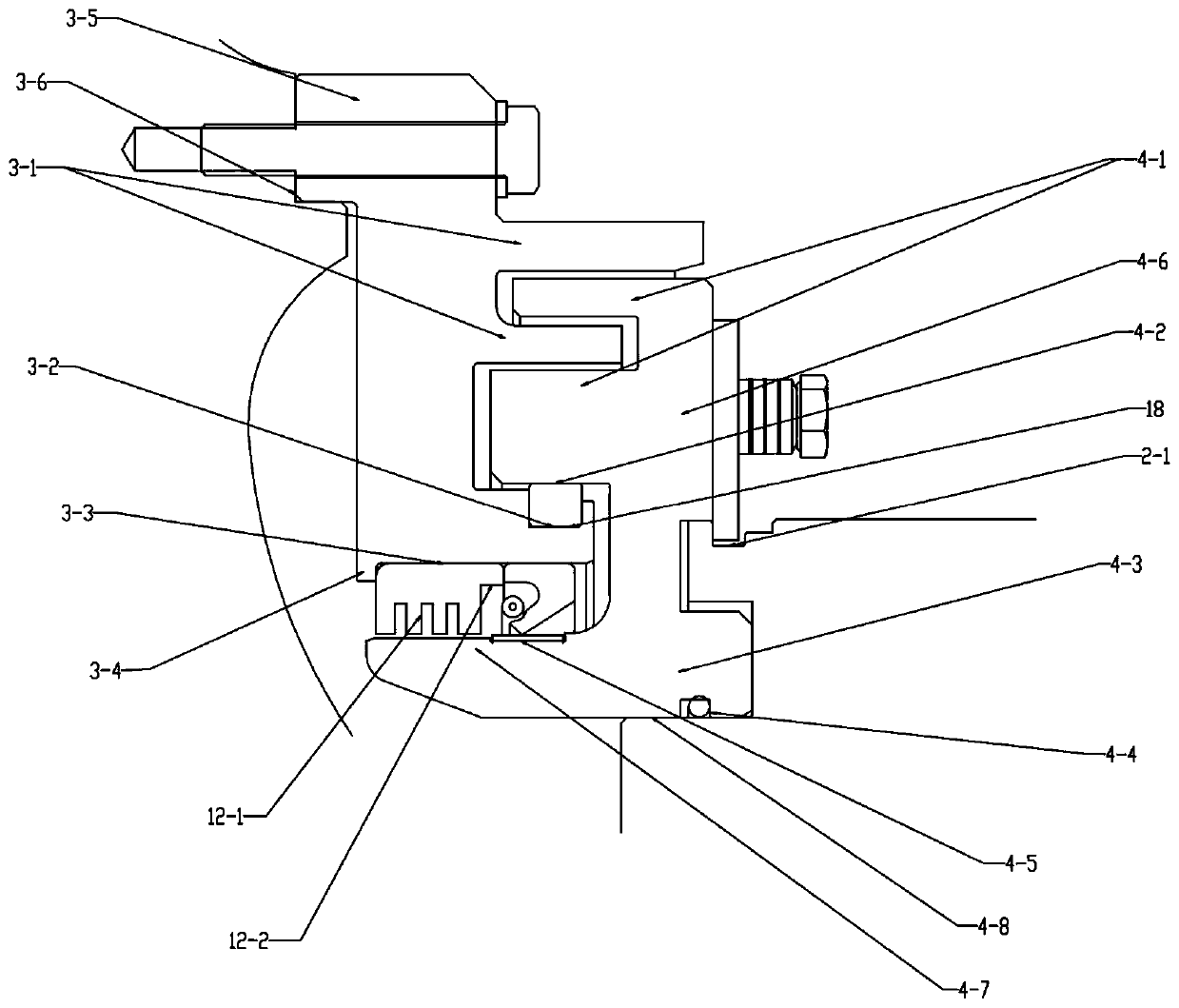

[0019] The combined sealing structure of the wheel reducer in this embodiment is applied in figure 1 The torque output end of the mine wheel side reducer shown is between the frame 1 connected with the rear axle of the vehicle and the torsion shaft 2 connected with the tires of the vehicle. The stationary ring 3 and the moving ring 4 are respectively fixed at the opposite positions of the frame 1 and the torsion shaft 2, specifically as figure 2 and image 3 As shown, the buckle edge 3-5 of the static ring 3 is assembled and fixed with the frame 1 of the wheel reducer through the static ring mounting bolt 5 and the anti-loosening gasket 6, and the inner stop of the buckle edge 3-5 is connected with the frame 1 The transition fit of the outer seam on the top, the assembly surface 3-6 of the static ring 3 and the frame 1—including the end surface and the seam mating surface are coated with end face sealant 7, which is used to prevent lubricating oil from the assembly surface 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com