Microporous ceramic heating body

A technology of microporous ceramics and heating elements, applied in the field of atomizers, can solve the problems of low heating efficiency and heating temperature of heating elements, large differences in the uniformity of ceramic surface hole distribution, and affecting the service life of ceramic heating elements, etc., to achieve service life Long, low cost, beneficial to the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

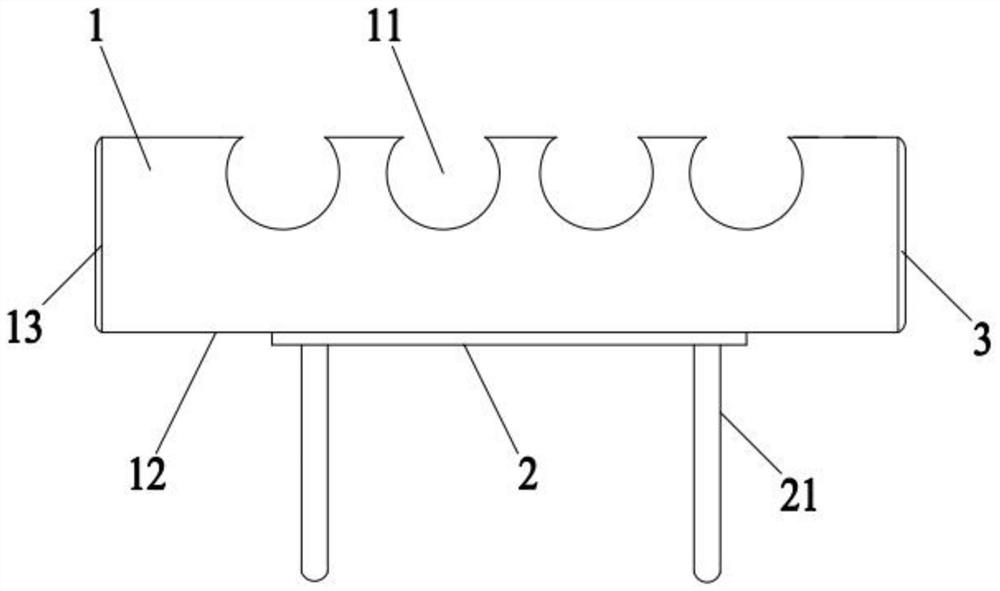

[0034] A microporous ceramic heating element, comprising a porous ceramic body 1 and a heating circuit 2, the top of the porous ceramic body 1 is recessed with a number of oil storage tanks 11, the oil storage tanks 11 are arranged at intervals, the outer surface of the porous ceramic body 1 The surface includes an atomizing surface 12 at the bottom of the porous ceramic body 1 and an oil sealing surface 13 at the side wall of the porous ceramic body 1, the outer surface of the oil sealing surface 13 is coated with a glass glaze layer 3, and the heating circuit 2 is set At the atomization surface 12, the porous ceramic body 1 is made by sintering a porous ceramic material; the two ends of the heating circuit 2 are respectively provided with lead wires 21, and the lead wires 21 are arranged in parallel; The shape of the oil storage tank 11 is a cylindrical tank.

[0035] The porous ceramic material includes the following raw materials in parts by weight: 20 parts of ceramic bon...

Embodiment 2

[0052] A microporous ceramic heating element, comprising a porous ceramic body 1 and a heating circuit 2, the top of the porous ceramic body 1 is recessed with a number of oil storage tanks 11, the oil storage tanks 11 are arranged at intervals, the outer surface of the porous ceramic body 1 The surface includes an atomizing surface 12 at the bottom of the porous ceramic body 1 and an oil sealing surface 13 at the side wall of the porous ceramic body 1, the outer surface of the oil sealing surface 13 is coated with a glass glaze layer 3, and the heating circuit 2 is set At the atomization surface 12, the porous ceramic body 1 is made by sintering a porous ceramic material; the two ends of the heating circuit 2 are respectively provided with lead wires 21, and the lead wires 21 are arranged in parallel; The shape of the oil storage tank 11 is a U-shaped groove.

[0053] The porous ceramic material includes the following raw materials in parts by weight: 25 parts of ceramic bone...

Embodiment 3

[0070] A microporous ceramic heating element, comprising a porous ceramic body 1 and a heating circuit 2, the top of the porous ceramic body 1 is recessed with a number of oil storage tanks 11, the oil storage tanks 11 are arranged at intervals, the outer surface of the porous ceramic body 1 The surface includes an atomizing surface 12 at the bottom of the porous ceramic body 1 and an oil sealing surface 13 at the side wall of the porous ceramic body 1, the outer surface of the oil sealing surface 13 is coated with a glass glaze layer 3, and the heating circuit 2 is set At the atomization surface 12, the porous ceramic body 1 is made by sintering a porous ceramic material; the two ends of the heating circuit 2 are respectively provided with lead wires 21, and the lead wires 21 are arranged in parallel; The shape of the oil storage tank 11 is a wedge-shaped groove.

[0071] The porous ceramic material includes the following raw materials in parts by weight: 30 parts of ceramic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com