Water-based ink for realizing matte effect of 3D glass as well as preparation method and application of water-based ink

A water-based ink and glass technology, applied in the field of ink, can solve problems such as the influence of 3D glass strength, and achieve the effect of protecting health, reducing pollution and saving usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

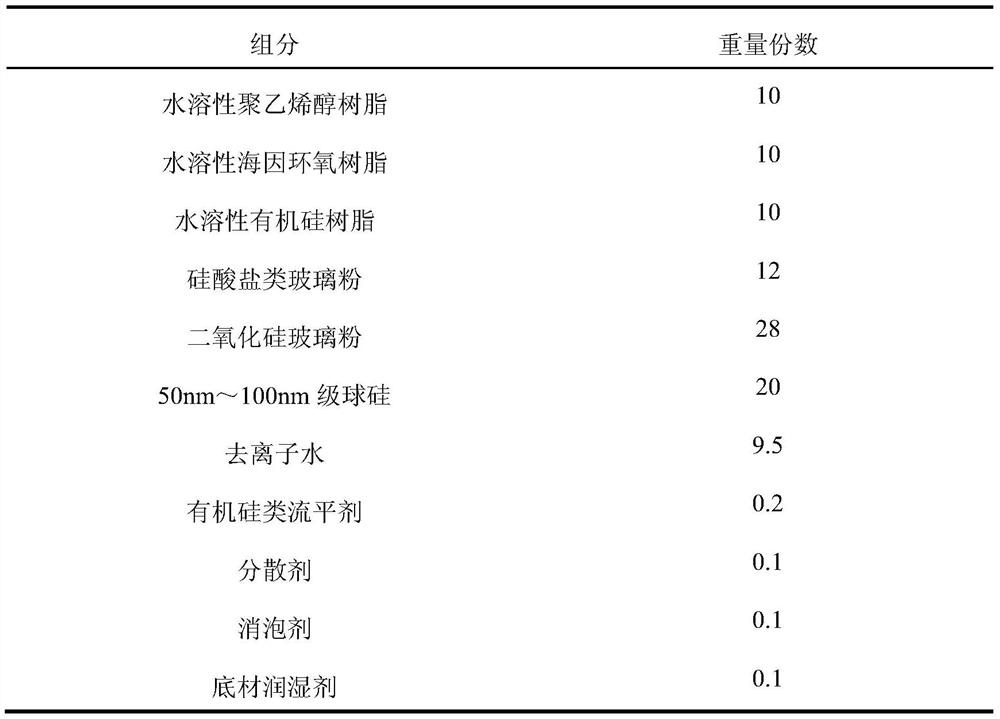

[0035] A preferred embodiment of the present invention provides a water-based ink for realizing the matte effect of 3D glass, which includes: parts by weight, as shown in Table 1.

[0036] Table 1 Example 1 is used to realize the formula of 3D glass matte effect

[0037]

[0038] Weigh them according to the formula dosage in Table 1, and add the materials in Table 1 sequentially while stirring under the condition of rotating speed of 1000r / min. Grind to a fineness of less than 2 μm to obtain a water-based ink for realizing the matte effect of 3D glass.

[0039] Take 20g of water-based ink that has been ground to achieve the matte effect of 3D glass, and print it on the 2D glass substrate with a 350-mesh screen. By adjusting the pressure and angle of the scraper, you can print fine patterns and bake in an oven at 180°C. Bake for 20 minutes to obtain a coating.

[0040] The above-mentioned 2D glass with the coating is subjected to bending treatment at a temperature of 650° ...

Embodiment 2

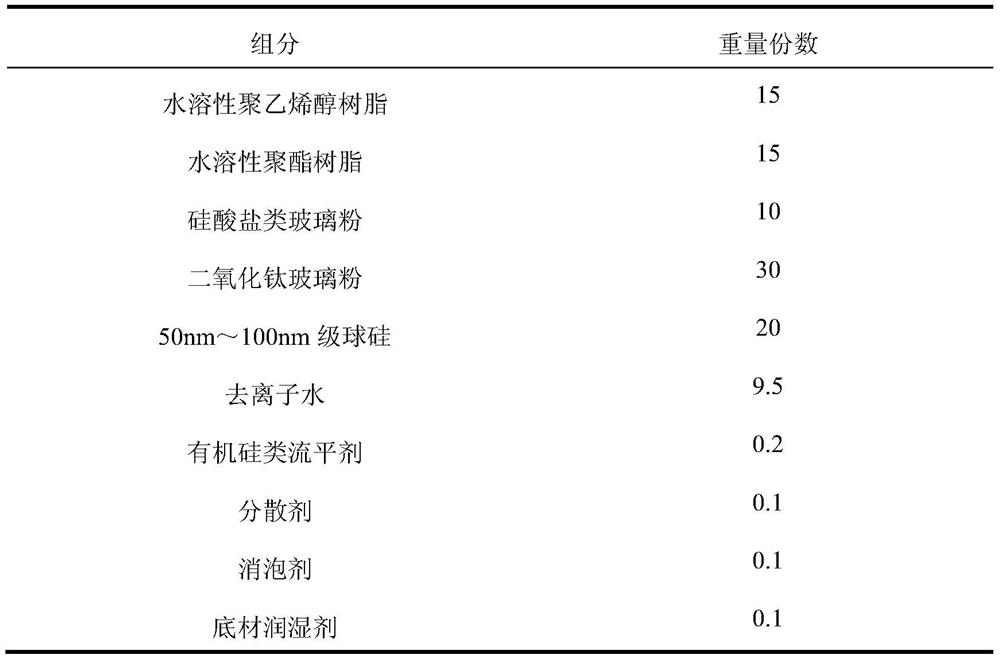

[0042] A preferred embodiment of the present invention provides a water-based ink for realizing the matte effect of 3D glass, which includes: in parts by weight, as shown in Table 2.

[0043] Table 2 Example 2 is used to realize the formula of 3D glass matte effect

[0044]

[0045] Weigh respectively according to the formula dosage in Table 2, under the condition of rotating speed of 1000r / min, add the materials in Table 2 sequentially while stirring, after mixing evenly, disperse for 25min at a rotating speed of 3000r / min, and put it on a sand mill Grind to a fineness of less than 2 μm to obtain a water-based ink for realizing the matte effect of 3D glass.

[0046] Take 20g of water-based ink that has been ground to achieve the matte effect of 3D glass, and print it on the 2D glass substrate with a 380-mesh screen. By adjusting the pressure and angle of the scraper, you can print fine patterns and bake in an oven at 170°C. Bake for 23 minutes to obtain a coating.

[0047]...

Embodiment 3

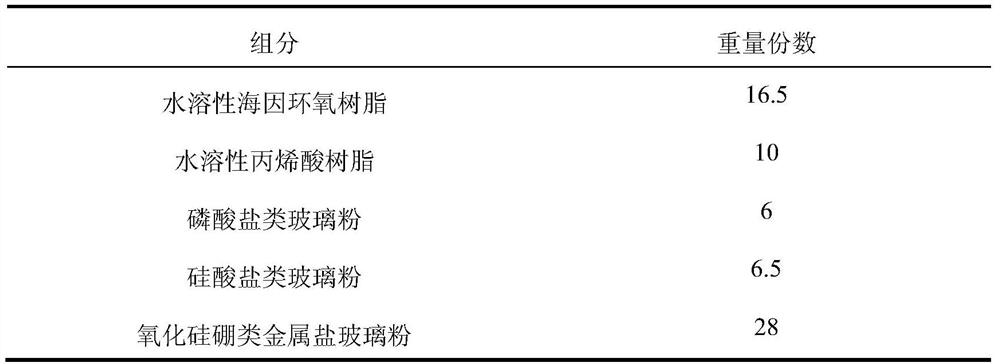

[0049] A preferred embodiment of the present invention provides a water-based ink for realizing the matte effect of 3D glass, which includes: in parts by weight, as shown in Table 3.

[0050] Table 3 Example 3 is used to realize the formula of 3D glass matte effect

[0051]

[0052]

[0053] According to the formula dosage in Table 3, weigh them respectively, under the condition of rotating speed of 1200r / min, add the materials in Table 3 one by one while stirring, after mixing evenly, then disperse for 28min at the rotating speed of 2800r / min, and put them on the sand mill Grind to a fineness of less than 2 μm to obtain a water-based ink for realizing the matte effect of 3D glass.

[0054] Take 20g of water-based ink that has been ground to achieve the matte effect of 3D glass, and print it on the 2D glass substrate with a 360-mesh screen. By adjusting the pressure and angle of the scraper, you can print a fine pattern and bake it in an oven at 170°C. Bake for 20 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com