Efficient environmentally-friendly oil-well wellhead sealing device

A sealing device, an environmentally friendly technology, applied in the directions of sealing/isolation, wellbore/well components, earth-moving drilling, etc., can solve the problems of environmental pollution, low production efficiency, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

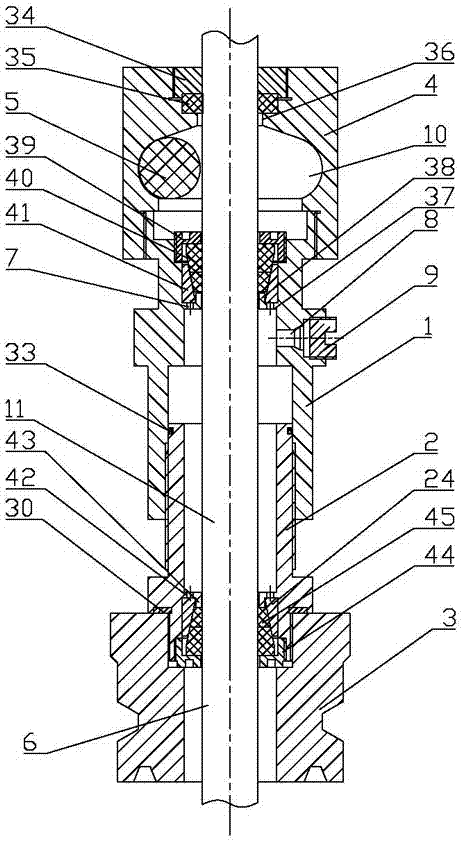

Embodiment 1

[0030] Embodiment one: as attached figure 1 As shown, the high-efficiency and environment-friendly oil well wellhead sealing device includes a blowout prevention device, a packing gland 1, a packing barrel 2 and a base 3, and the blowout prevention device includes a blowout prevention casing 4, a blowout prevention sealing assembly and a blowout prevention ball 5; The spray housing 4, the packing gland 1, the packing tube 2 and the base 3 are fixedly installed together from top to bottom. The lower support ring seat is installed under the lower support ring seat with the lower packing sealing ring sleeve whose top surface is against the lower support ring seat. The upper inner side of the packing gland 1 is fixed with the upper support ring seat, which is installed above the upper support ring There is an upper packing sealing ring sleeve with a bottom seat on the upper support ring seat, pressurized through holes 7 are distributed along the circumference intervals on the bott...

Embodiment 2

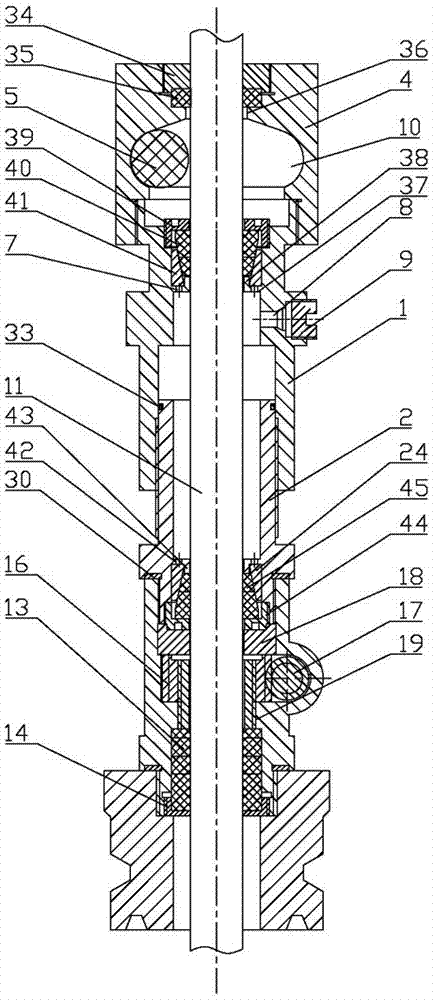

[0031] Embodiment two: as attached figure 2 , 5 , 6, and 7, on the basis of Embodiment 1, a well sealing device is also included, and a well sealing device is provided between the packing tube 2 and the base 3, and the well sealing device includes a well sealing cylinder body 12, a well sealing rubber ring 13 , sealing gland 14, screw gland 15, rotating worm gear 16, worm screw 17 and turbine gland 18, the inner side of the upper end of the sealing casing 12 and the outer side of the lower end of the packing casing 2 are fixedly installed together through threaded connection, the sealing casing The outer side of the lower end of 12 and the inner side of the upper end of the base 3 are fixedly installed together through threaded connection; a sealing gland 14 is fixedly installed on the inner side of the lower end of the sealing cylinder 12, and the inner side of the sealing cylinder 12 corresponding to the position above the sealing gland 14 is fixed. There is an inner ring ...

Embodiment 3

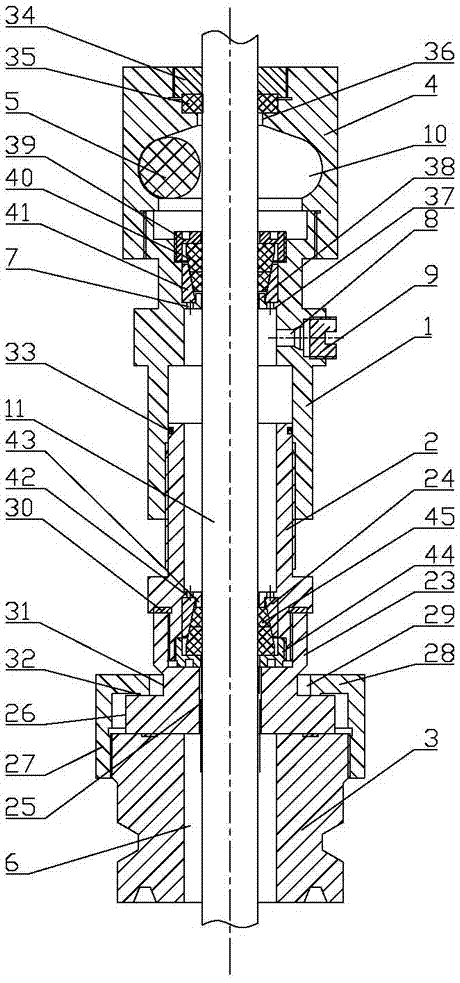

[0032] Embodiment three: as attached image 3 As shown, on the basis of Embodiment 1, a centering plate 23 and a centering gland are also included, and a centering plate 23 is provided between the packing tube 2 and the base 3, and the middle part of the centering plate 23 is provided with a diameter smaller than a seat The disc body through hole 25 of the body through hole 6, the inner side of the upper end of the centering disc 23 is fixedly installed together with the outer side of the lower end of the packing tube 2 through threaded connection, and the outer side of the lower end of the centering disc 23 is provided with an outer seat on the base 3. The ring platform 26; the centering gland includes a centering pressure sleeve 27 and a limit ring cover 28, and the centering pressure sleeve 27 is set on the outside of the outer ring platform 26, and the inner side of the lower end of the centering pressure sleeve 27 and the outer side of the upper end of the base 3 Fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com