Improved mechanical turbocharger

A technology of turbocharger and turbocharger shell, applied in mechanical equipment, machine/engine, engine components, etc., can solve the problems of reduced lubrication performance, wear of gear box internal parts, gearbox oil leakage, etc., to ensure Lubrication performance, the effect of avoiding oil seepage or oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

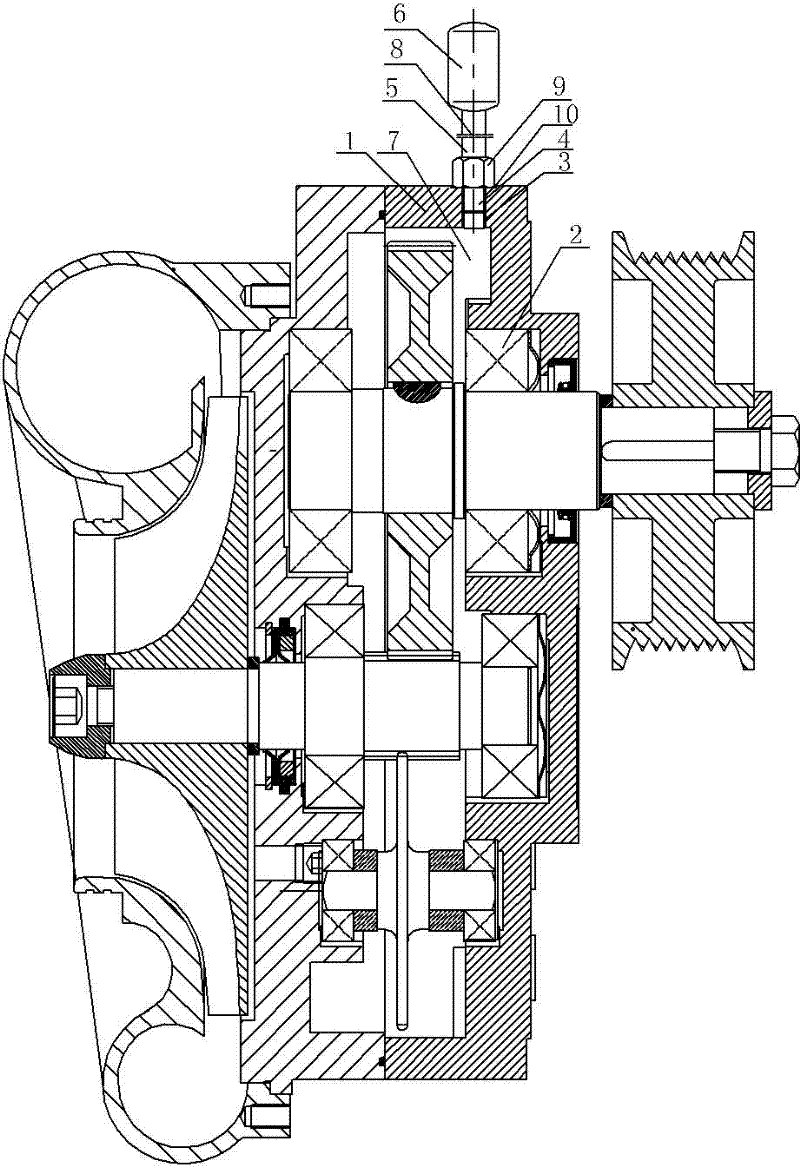

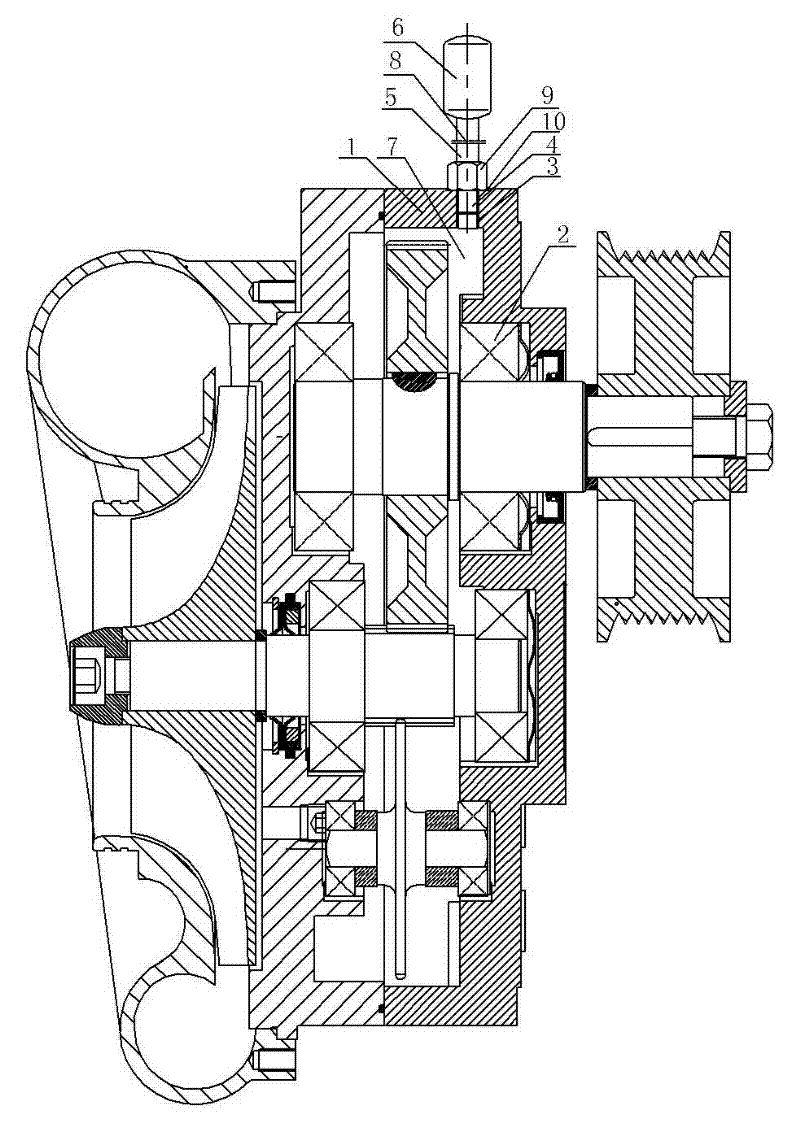

[0008] See figure 1 , the present invention comprises gear box 2, and gear box 2 is installed in turbocharger casing 1, and screw hole 3 is set on turbocharger casing 1, and screw hole 3 is a through hole, and it is connected with the inside of turbocharger. The cavity 7 and the gear box 2 are connected, and the hydraulic pipe joint 4 is installed in the threaded hole 3. The hydraulic pipe joint 4 is connected to the hydraulic pipe 5. The threaded hole 3 is "T" type, and the hydraulic pipe joint 4 is screwed to the hydraulic pipe 5 through the nut 9. The nut 9 falls into the upper end surface 10 of the "T" threaded hole 3, the hydraulic pipe 5 is connected to the respirator 6, and the clamp 8 is set in the middle of the hydraulic pipe 5 (the function of the clamp 8 can adjust the opening of the air circuit). The respirator 6 is a mature technology. The respirator 6 has a built-in filter capable of separating oil and gas and absorbing tiny particles. The mixture rushes to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com