Automobile composite pipe provided with fluorine-containing outer layer and silicon-containing inner layer

A composite pipe, automobile technology, applied in the direction of hose, pipe, pipe/pipe joint/pipe fitting, etc., can solve the problems of poor adhesion between the adhesive layer and the reinforcement layer, low production efficiency, uneven wall thickness, etc., to ensure The effect of wall thickness consistency and stability, prolonging service life, and reducing failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

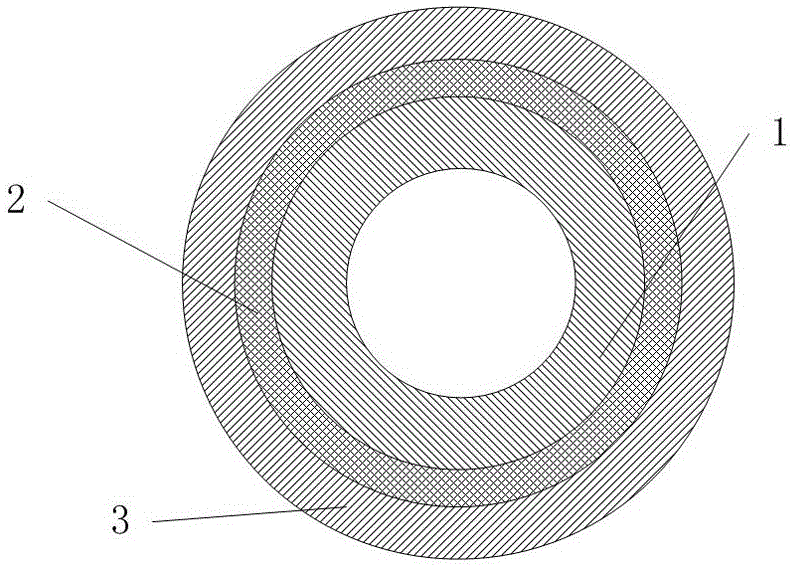

[0025] A fluorine-inner-silicon composite pipe for automobiles, comprising a fluorine-rubber inner layer 1, a reinforcement layer 2 and a silica gel outer layer 3, the inner wall of the automobile-use outer-fluorine-inner-silicon composite pipe is a fluorine rubber inner layer, and the reinforcement layer is coated The outer wall of the inner layer of fluorine rubber, the outer wall of the silicone rubber is covered on the outer wall of the reinforcement layer. In this structure, the inner layer of fluorine rubber is resistant to high temperature, has good air tightness and oil resistance, and can effectively prevent oil and water seepage from the hose.

Embodiment 2

[0027] Same as Example 1, the difference is that the inner layer of the fluororubber is fluororubber, and the fluororubber is vinylidene fluoride fluororubber. In this vinylidene fluoride fluororubber, relative to the The total amount of structural units is 100 mol%, containing 48 mol% to 88 mol% of structural units derived from vinylidene fluoride, and 0 mol% to 10 mol% of structural units derived from tetrafluoroethylene, relative to 100 parts by mass of fluororubber, containing 5 to 50 parts by mass of carbon black; the fluororubber composition contains a crosslinking agent. Using the fluororubber provided by the present invention can further improve the heat resistance, and the mechanical properties at high temperature are also better than other fluororubber molded products.

Embodiment 3

[0029] Same as Example 1, the difference is that the reinforcing layer is made of nano-silver fiber combined with glass fiber blend spinning, and is wound in the inner layer of fluorine rubber in a double helix structure. The reinforcing layer is bonded to the inner layer of fluorine rubber and the silica gel layer through an adhesive composed of triazine thiol and diene rubber in a laminated state. The reinforcing layer can effectively ensure the strength of the inner layer of fluorine rubber, and at the same time be resistant to high temperature and oxidation. The adhesive of the invention can effectively improve the adhesion between layers and avoid separation between layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com