Novel underground mine gel emulsion explosive and preparation method thereof

A technology of emulsion explosives and underground mines, which is applied in the field of explosives, can solve the problems of poor fluidity, affect the pumping effect, and reduce the viscosity of emulsion explosives, achieve stable physical and chemical properties, facilitate automatic pumping, and improve fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

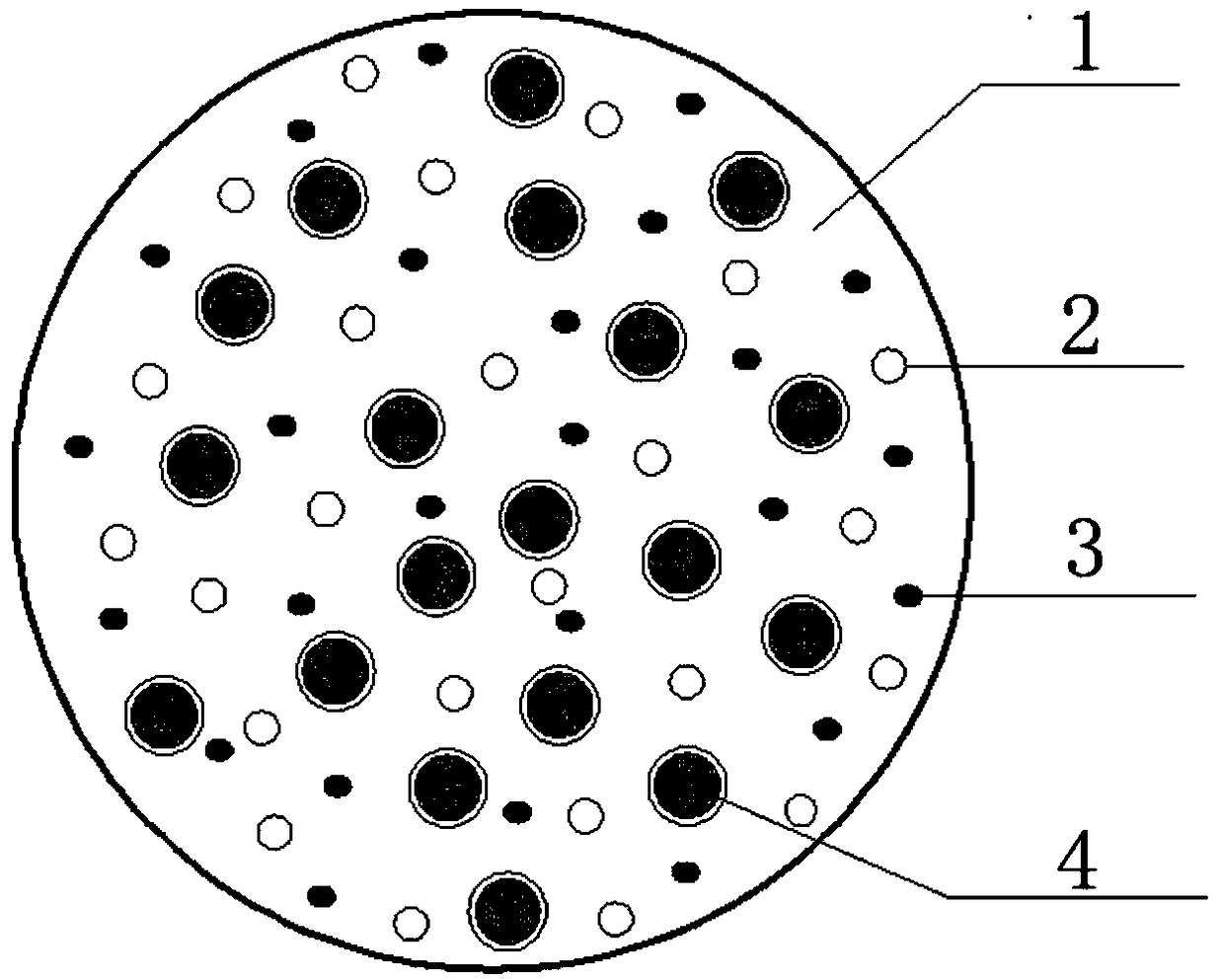

Image

Examples

Embodiment 1

[0031] New colloidal emulsion explosive for underground mining: the colloidal emulsion explosive for underground mining contains 73 parts of ammonium nitrate, 5 parts of sodium nitrate, 5 parts of composite oil phase, 10 parts of water, NaNO 2 0.2 parts, 3 parts of sodium lignosulfonate, 3 parts of sodium polyacrylate, and 0.8 parts of polymethacrylate.

[0032] The preparation method of described novel colloidal emulsion explosive for underground mining comprises the following steps:

[0033] St1: Coating of sodium polyacrylate: Microcapsule method is used to cover sodium polyacrylate with microcapsules made of polymethacrylate, and the average particle size of the microcapsules is controlled at 10-45 microns.

[0034] St2: Preparation of latex matrix: Mix and stir ammonium nitrate, sodium nitrate, composite oil phase, water and sodium lignosulfonate in proportion, and control the production process conditions to prepare a latex matrix with good fluidity.

[0035] St3: Prepa...

Embodiment 2

[0040] New colloidal emulsion explosive for underground mining: the colloidal emulsion explosive for underground mining contains 72 parts of ammonium nitrate, 5 parts of sodium nitrate, 5 parts of composite oil phase, 9 parts of water, 1.2 parts of resin microspheres, sodium polynaphthaldehyde sulfonate 4 parts, Tianqing glue 3 parts, polylaurolactam 0.8 parts.

[0041] The preparation method of described novel colloidal emulsion explosive for underground mining comprises the following steps:

[0042] St1: Coating of Tianqing gum: Microcapsule method is used to coat Tianqing gum with microcapsules made of polylaurolactam, and the average particle size of the microcapsules is controlled at 10-45 microns.

[0043] St2: Preparation of latex matrix: Mix and stir ammonium nitrate, sodium nitrate, composite oil phase, water and sodium polynaphthalene sulfonate according to the mass ratio, and control the production process conditions to prepare a latex matrix with good fluidity.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com