Stabilized energetic water-in-oil emulsion composition

a technology of energetic water in oil and composition, applied in the direction of weapons, non-explosive fillers/gelling/thickening agents, explosives, etc., can solve the problems of affecting the performance of emulsions, adding further internal stress to the emulsion, and affecting the composition performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0084]The following example illustrates an emulsion composition of this invention and means for preparing it. This example is intended to be illustrative only and is not intended to limit the scope of the invention. Unless indicated otherwise, all parts are parts by weight and temperatures are in degrees Celsius. All analytical values are by analysis.

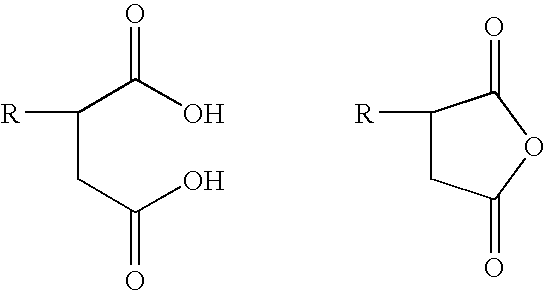

[0085]An aqueous component containing 81.25 parts ammonium nitrate, 19.50 parts tap water and 0.25 parts Zn(NO3)2, is heated with mixing to 71° C. An organic component containing 1.35 parts of a 52% in mineral oil solution of a half-ester salt, half amide ester prepared by reacting polyisobutenyl ({overscore (M)}n) substituted succinic anhydride with diethanol amine (the emulsifier), 0.7 parts sorbitan monooleate (co-emulsifier), 0.5 parts dioctyl adipate, 0.5 parts maleinated polybutadiene (LUCANT 6020H) and 3.35 parts diesel fuel oil is also heated with mixing to 71° C. The aqueous component (96.4 parts) is poured, with mixing over 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com