Moisture-proof smokeless sulfur-free propellant for fireworks and preparation method thereof

A technology for propellant and fireworks, which is applied in directions such as explosives, can solve problems such as the danger of firecracker propellants, and achieve the effects of being suitable for large-scale production, easy to obtain raw materials and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

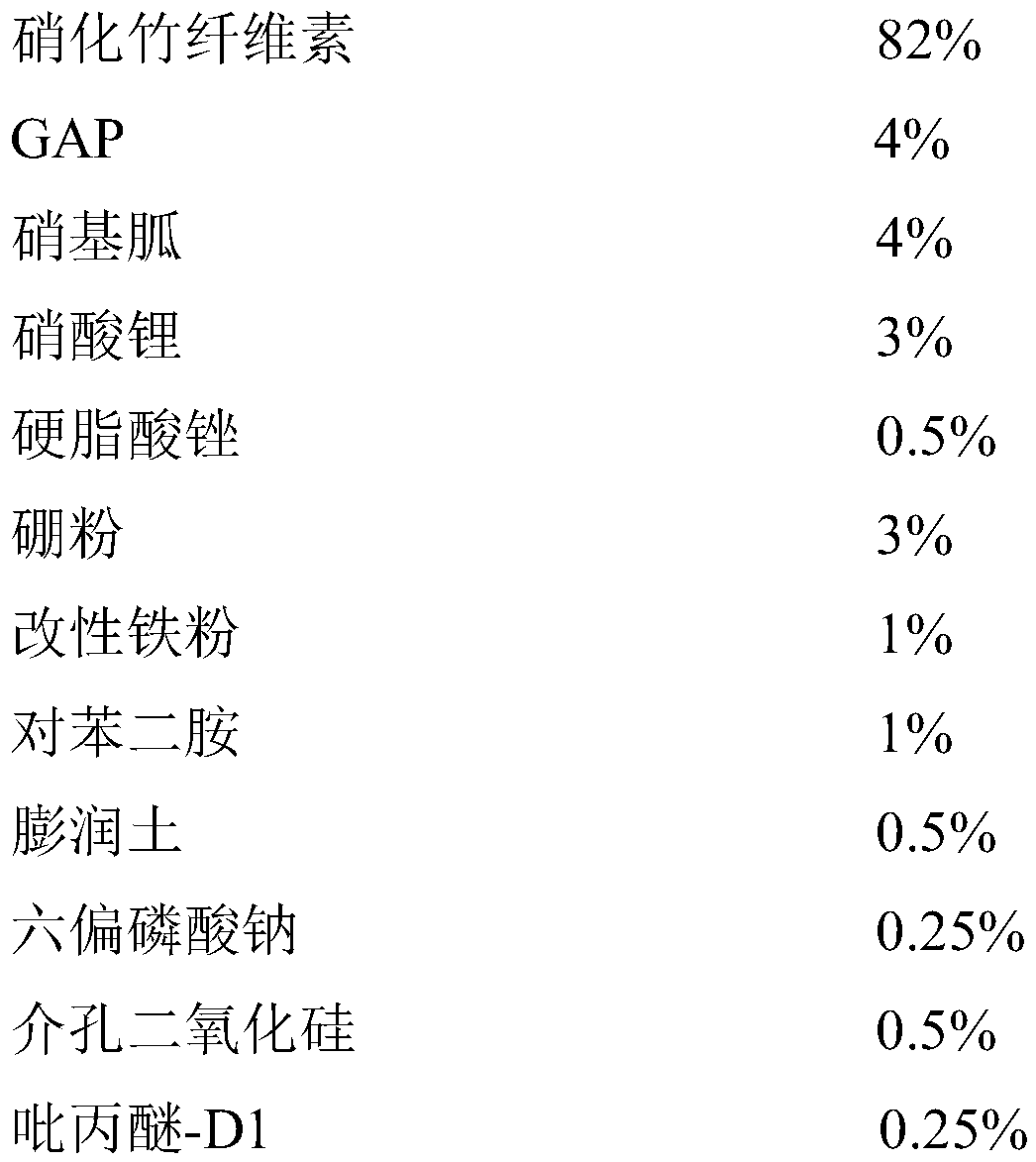

[0034] A moisture-proof smokeless and sulfur-free propellant for fireworks, the formula of which is as follows:

[0035]

[0036] A method for preparing a moisture-proof smokeless and sulfur-free propellant for fireworks, comprising the steps of:

[0037] Step 1, weigh 0.3g shellac and 15g iron powder (350 mesh) by mass ratio 1:50, dissolve shellac in 80mL n-amyl alcohol solvent, obtain the shellac solution that concentration is 0.47%, add iron wherein After ultrasonication for 1 hour at room temperature in an ultrasonic water bath, transfer to an oil bath at 40°C, and after stirring for 3 hours, add 320 mL of precipitant cyclohexane dropwise, complete the dropwise addition in 20 minutes, continue stirring for 40 minutes and then stop , after standing at room temperature, filter, wash the filter residue with cyclohexane for 3 times, transfer to a blast oven and dry at 80°C for 6 hours to obtain modified iron powder;

[0038] Step 2, weigh 8.2g nitrobamboo cellulose, 0.4g G...

Embodiment 2

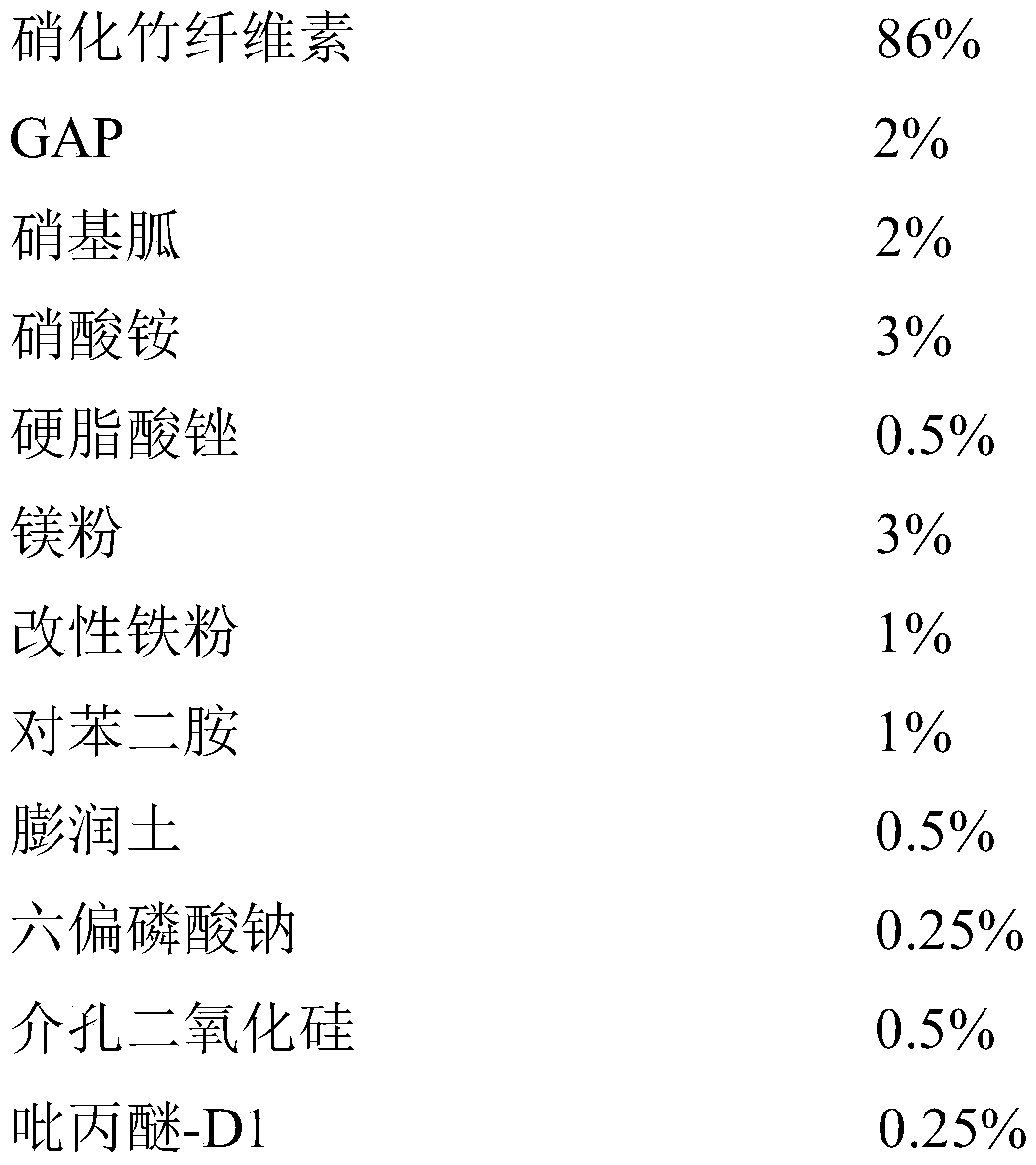

[0049] A moisture-proof smokeless and sulfur-free propellant for fireworks, the formula of which is as follows:

[0050]

[0051] A method for preparing a moisture-proof smokeless and sulfur-free propellant for fireworks, comprising the steps of:

[0052] Step 1. Weigh 1g shellac and 60g iron powder (350 mesh) according to the mass ratio of 1:60, dissolve shellac in 250mL n-amyl alcohol solvent to obtain a shellac solution with a concentration of 0.50%, and add iron powder thereto After ultrasonication for 1 hour at room temperature in an ultrasonic water bath, transfer to an oil bath at 40°C, and after stirring for 3 hours, add 1L of precipitating agent cyclohexane dropwise, continue stirring for 40 minutes after 25 minutes, and then stop. After standing at room temperature, filter, wash the filter residue with cyclohexane for 3 times, transfer to a blast oven and dry at 80°C for 6 hours to obtain modified iron powder;

[0053] Step 2: Take by weighing 43g nitrobamboo cel...

Embodiment 3

[0064] A moisture-proof smokeless and sulfur-free propellant for fireworks, the formula of which is as follows:

[0065]

[0066] A method for preparing a moisture-proof smokeless and sulfur-free propellant for fireworks, comprising the steps of:

[0067] Step 1, weigh 0.2g shellac and 7.5g iron powder (350 mesh) according to mass ratio 2:75, dissolve shellac in 80mL n-amyl alcohol solvent, obtain the shellac solution that concentration is 0.31%, add wherein For iron powder, after ultrasonication for 1 hour at room temperature in an ultrasonic water bath, transfer it to an oil bath at 40°C, stir for 3 hours, add 350 mL of precipitant cyclohexane dropwise, finish adding dropwise in 20 minutes, continue stirring for 40 minutes Stop, let stand at room temperature and then filter, wash the filter residue 3 times with cyclohexane, transfer to a blast oven and dry at 80°C for 6 hours to obtain modified iron powder;

[0068] Step 2, weigh 17g nitrobamboo cellulose, 0.4g GAP, 0.6g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com