Antistatic, smokeless and sulfur-free propellant for fireworks, and preparation method thereof

An anti-static and propellant technology, applied in explosives processing equipment, explosives, offensive equipment and other directions, can solve the problems of poor storage stability, large amount of toxic fumes, general anti-static effect, etc., to achieve good stability and preparation technology. Simple, good antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

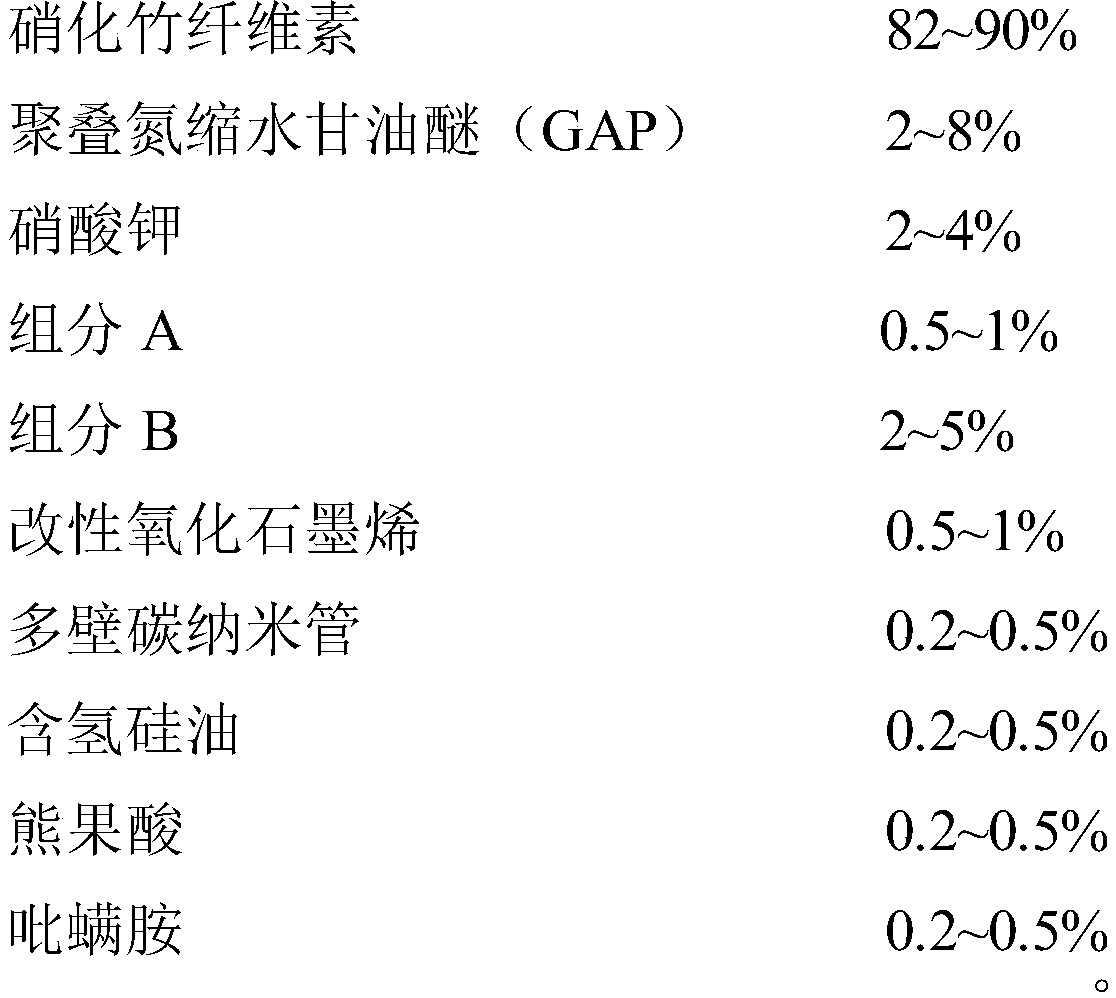

[0031] An antistatic smokeless and sulfur-free propellant for fireworks, the mass percentage of each component is as follows:

[0032]

[0033] The specifications of the beryllium powder in the components are: the average particle size is 1um, the purity is >99.9%, and the specific surface area is 12.0 (m 2 / g), the bulk density is 1.2(g / cm 3 )

[0034] A preparation method of an antistatic smokeless and sulfur-free propellant for fireworks, comprising the steps of:

[0035] Step 1. Weigh 1.5g of graphene oxide, 0.1g of ethylenediaminetetraacetic acid disodium salt, 0.1g of trisodium citrate dihydrate, 0.15g of daidzein according to the mass ratio of 15:1:1:1.5, and the graphite oxide Graphene was added to 30mL methanol solution, and after ultrasonication at 3°C for 40 minutes, a graphene oxide suspension with a concentration of 5.94% was obtained, which was transferred to a reaction kettle, and ethylenediaminetetraacetic acid disodium salt and trisodium citrate dihydra...

Embodiment 2

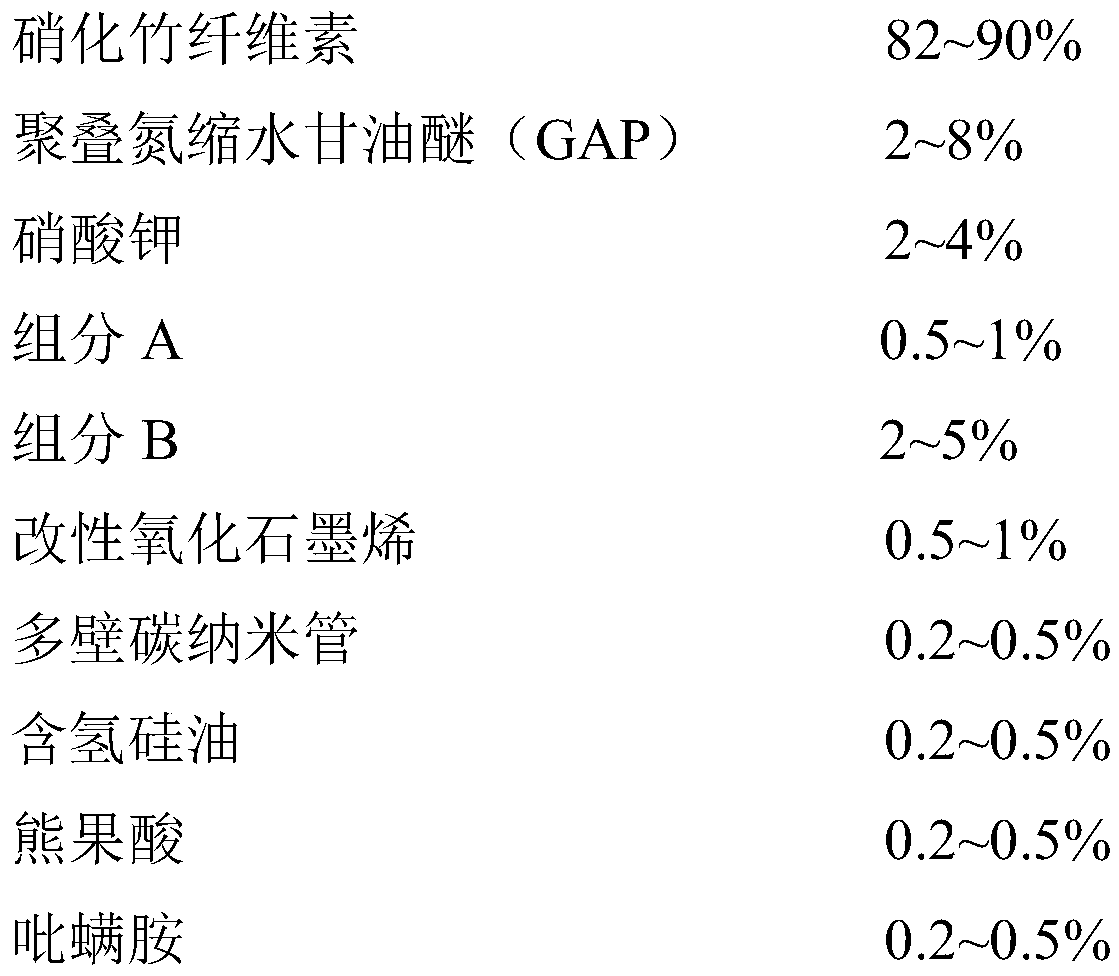

[0046] An antistatic smokeless and sulfur-free propellant for fireworks, the mass percentage of each component is as follows:

[0047]

[0048] The magnesium powder specifications described in the components are: the average particle diameter is 1um, the purity>99.9%, and the specific surface area is 9.0 (m 2 / g), the bulk density is 1.0(g / cm 3 )

[0049] A preparation method of an antistatic smokeless and sulfur-free propellant for fireworks, comprising the steps of:

[0050] Step 1. Weigh 4g of graphene oxide, 0.2g of ethylenediaminetetraacetic acid disodium salt, 0.26g of trisodium citrate dihydrate, and 0.34g of daidzein according to the mass ratio of 2:0.1:0.13:0.17. Add it into 60mL of methanol solution, and after ultrasonication for 40 minutes at 2°C, a graphene oxide suspension with a concentration of 7.77% is obtained, which is transferred to a reaction kettle, and ethylenediaminetetraacetic acid disodium salt, trisodium citrate dihydrate and Daidzein, stirred u...

Embodiment 3

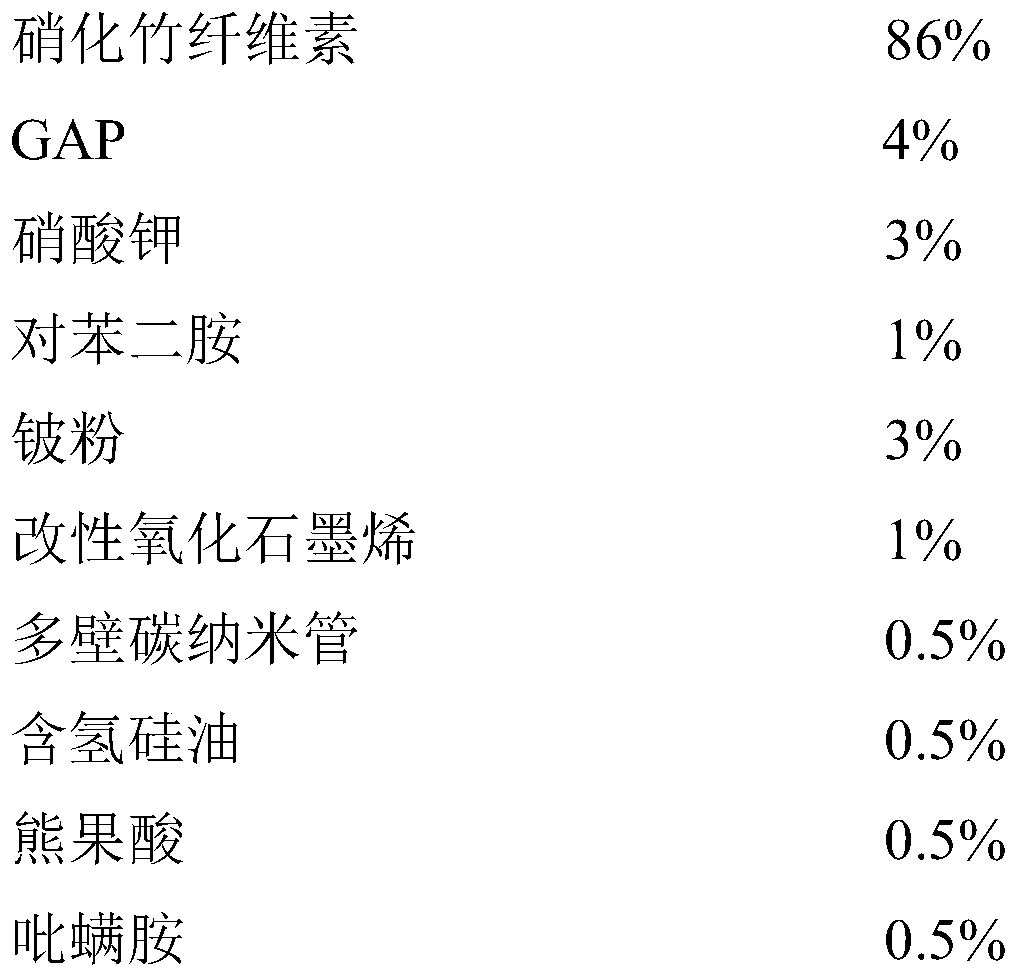

[0061] An antistatic smokeless and sulfur-free propellant for fireworks, the mass percentage of each component is as follows:

[0062]

[0063] The specifications of the aluminum powder in the components are: the average particle size is 1um, the purity is >99.9%, and the specific surface area is 9.0(m 2 / g), the bulk density is 0.73(g / cm 3 )

[0064] A preparation method of an antistatic smokeless and sulfur-free propellant for fireworks, comprising the steps of:

[0065] Step 1. Weigh 5g of graphene oxide, 0.26g of ethylenediaminetetraacetic acid disodium salt, 0.26g of trisodium citrate dihydrate, and 0.5g of daidzein according to the mass ratio of 2.5:0.13:0.13:0.25. Add it into 80mL of methanol solution, and after ultrasonication for 40 minutes at 0°C, a graphene oxide suspension with a concentration of 7.32% is obtained, which is transferred to a reaction kettle, and ethylenediaminetetraacetic acid disodium salt, trisodium citrate dihydrate and Daidzein, stirred un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com