Method for determining relative rate of curing reaction of glycidyl azide polymer adhesive

A technology of glycidyl ether and curing reaction, applied in flow characteristics, measuring devices, instruments, etc., can solve problems such as interference and undetectable heat, and achieve the effects of easy operation, fast and simple data processing, and saving chemical reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In the following, the present invention will be further described in conjunction with the embodiments.

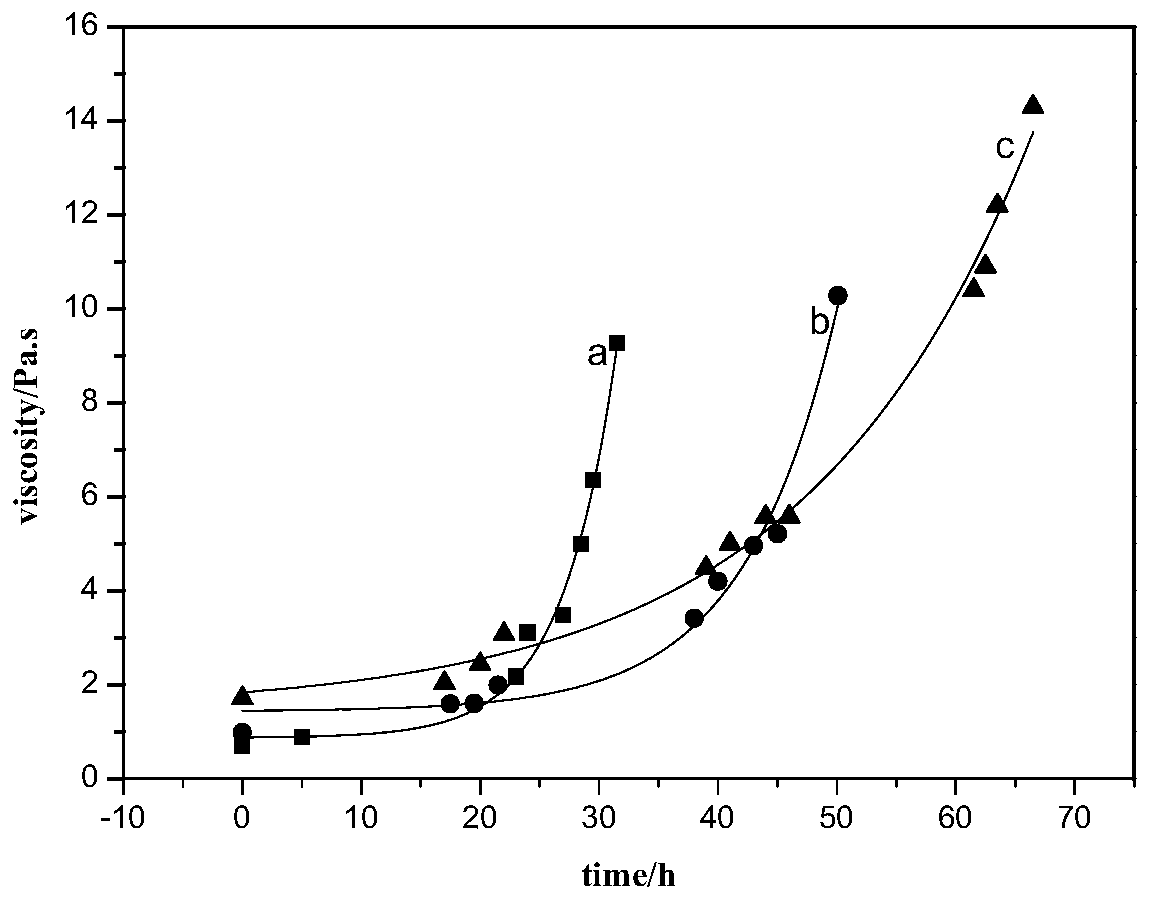

[0031] (1) Weigh 20g each of the three GAP adhesives with different hydroxyl values, put them in three beakers, add 0.06g of the catalyst triphenylbismuth, stir evenly, and the ratio of the amount of isocyanate group to hydroxyl group is 1 :1 accurately add 1.16g, 0.73g, 0.42g toluene diisocyanate respectively to form three curing reaction systems GAP-TDI-1, GAP-TDI-2 and GAP-TDI-3 continue to stir to mix the curing reaction system Evenly, immediately put it into a 50℃ oil bath oven for curing reaction.

[0032] (2) At different time points in the curing reaction process, take out a small amount of samples of the curing system GAP-TDI-1 from the oven, use a rheometer to immediately test the viscosity of the sample, and continue to cure the other two systems in the oven. The same test is performed on the curing system GAP-TDI-2 and the curing system GAP-TDI-3. The freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com