Quickly-cured GAP (Glycidyl Azide Polymer)-based mixture

A rapid curing and mixture technology, applied in the direction of offensive equipment, compressed gas generation, explosives, etc., can solve the problems of low curing rate, long curing time, and affecting the performance of the cured product, and achieve the advantages of small glue viscosity and short curing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

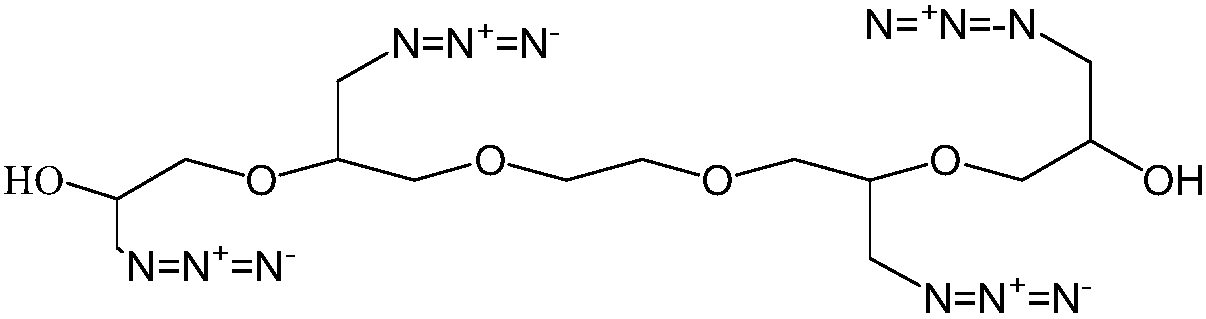

Image

Examples

Embodiment 1

[0014] The present invention is implemented with reference to the following composition by mass percentage: 90% GAP, 9.99% dipropynyl succinate, and 0.01% triphenyl bismuth. Wherein the number average molecular weight of GAP is 3698g / mol, and the N content in GAP is 41.72%.

[0015] Preparation:

[0016] (1) Glue preparation

[0017] Weigh 9.99g of dipropynyl succinate and place it in a rotary mixer, let stand at 60°C for 10 minutes, add 90g of GAP, stir in vacuum for 20 minutes, add 0.01g of triphenylbismuth and stir for 10 minutes to obtain a uniformly mixed glue.

[0018] (2) sample preparation

[0019] The glue solution was poured into the tetrafluoroethylene mold by vacuum pouring process, and cured at 60°C until the hardness remained constant to test the curing time and performance test.

[0020] The curing time of Example 1 was reduced to 20 hours from 60 hours when TDI was used as the curing agent and 72 hours when N-100 was used as the curing agent, and the curing ...

Embodiment 2

[0022] The present invention is implemented with reference to the following composition by mass percentage: 88.89% GAP, 11.10% dipropynyl succinate, and 0.01% triphenyl bismuth. Wherein the number average molecular weight of GAP is 3698g / mol, and the N content in GAP is 41.72%.

[0023] Preparation:

[0024] (1) Glue preparation

[0025] Weigh 11.10g of dipropynyl succinate and place it in a rotary mixer, let stand at 60°C for 10 minutes, add 88.89g of GAP, stir in vacuum for 20 minutes, add 0.01g of triphenylbismuth and stir for 10 minutes to obtain a uniformly mixed glue.

[0026] (2) sample preparation

[0027] The glue solution was poured into the tetrafluoroethylene mold by vacuum pouring process, and cured at 60°C until the hardness remained constant to test the curing time and performance test.

[0028] The curing time of Example 2 is reduced to 18 hours from 60 hours when TDI is used as the curing agent and 72 hours when N-100 is used as the curing agent, and the cu...

Embodiment 3

[0030] The present invention is implemented with reference to the following composition by mass percentage: 91.67% GAP, 8.33% dipropynyl succinate, and 0.01% triphenylbismuth. Wherein the number average molecular weight of GAP is 3698g / mol, and the N content in GAP is 41.72%.

[0031] Preparation:

[0032] (1) Glue preparation

[0033] Weigh 8.33g of dipropynyl succinate and place it in a rotary mixer, let stand at 60°C for 10 minutes, add 91.67g of GAP, stir in vacuum for 20 minutes, add 0.01g of triphenylbismuth and stir for 10 minutes to obtain a uniformly mixed glue.

[0034] (2) sample preparation

[0035] The glue solution was poured into the tetrafluoroethylene mold by vacuum pouring process, and cured at 60°C until the hardness remained constant to test the curing time and performance test.

[0036] The curing time of Example 3 was reduced to 22 hours from 60 hours when TDI was used as the curing agent and 72 hours when N-100 was used as the curing agent, and the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com