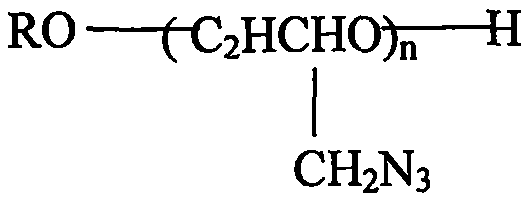

GAP (glycidyl azide polymer) as well as preparation method and application thereof

A technology of glycidyl ether and azidation, which is applied in the field of fuel oil, can solve the problems of poor miscibility of fuel oil, etc., and achieve the effects of reducing exhaust emissions, increasing solubility, and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Keep the temperature of the system at 50-60°C, add 7.4g of butanol to the reactor after nitrogen replacement, and dissolve 0.52g of SnCl in 50ml 4 and 1.14g CF 3 Toluene solution of COOH, 18.5g epichlorohydrin monomer (ECH), heat preservation reaction for 2h. After the reaction was completed, 22.3 g of PECH was obtained after washing with water, distillation under reduced pressure, and filtration. According to GPC analysis, the number average molecular weight Mn=286.

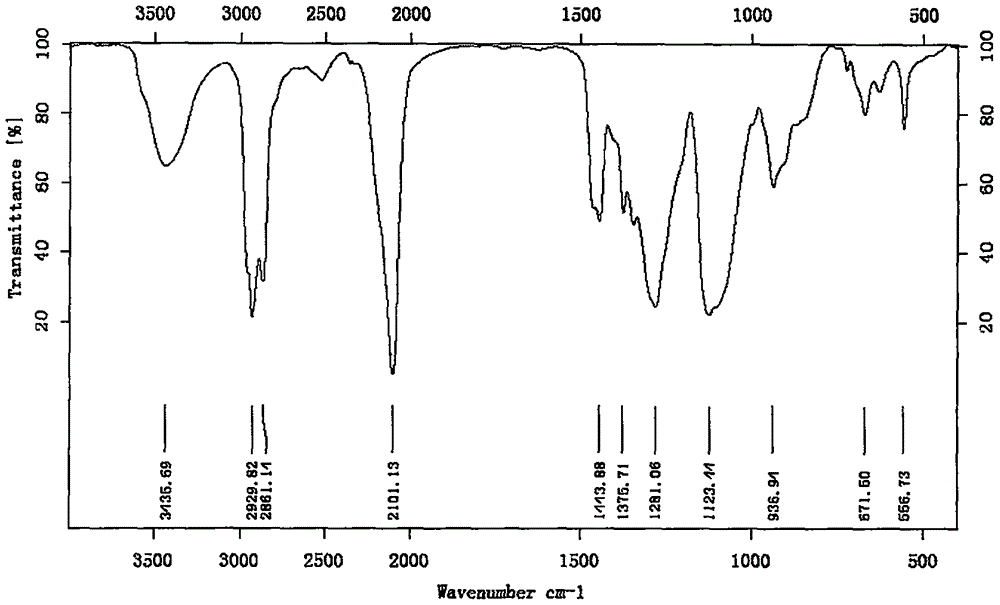

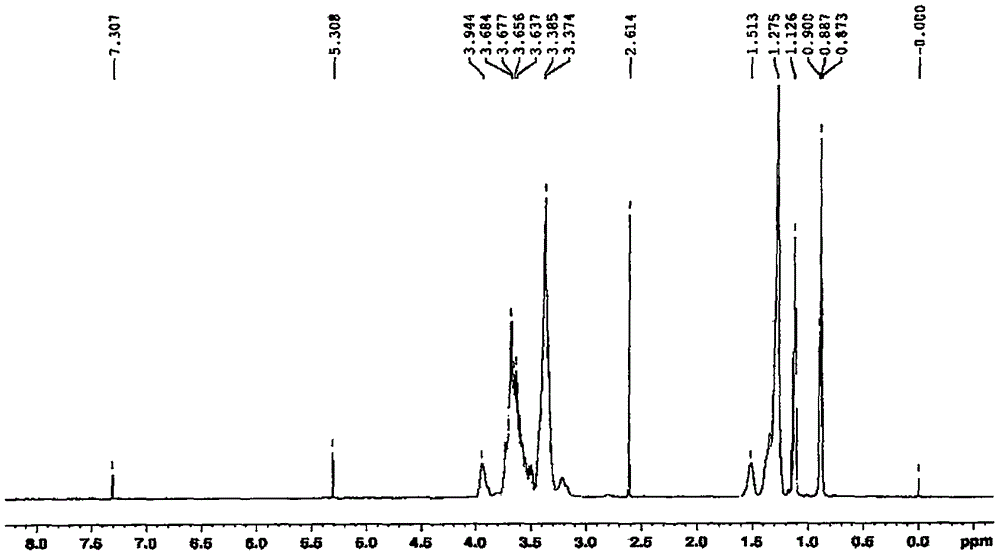

[0025] (2) Add the above 22.3g PECH into the reactor, add the same quality of DMF, add 16gNaN 3 , 0.03g tetrabutylammonium bromide, reacted at 100°C for 10h, after the reaction was completed, washed with water and dried to obtain a light yellow liquid GAP. The infrared spectrum and NMR spectrum of the product are respectively shown in the appendix of the instruction manual. figure 1 And attached figure 2 . After analysis, the product number average molecular weight M n =309; hydroxyl value: 178...

Embodiment 2

[0028] (1) Add 50ml of toluene to the reactor after nitrogen replacement, keep the system temperature at 0-10°C, add 18.6g of dodecanol, 0.52g of BF 3 ·OEt 2 , 46.25g epichlorohydrin (ECH) monomer, continue to react for 5h. After the reaction was completed, 60.7 g of PECH was obtained after washing with water, distillation under reduced pressure, and filtration. According to GPC analysis, the number average molecular weight Mn=642.

[0029] (2) Add the above PECH into the reactor, add the same mass of DMSO, add 40gNaN 3 , 0.06g of lithium chloride catalyst was reacted at 100°C for 10h, after the reaction was completed, 58.4g of light yellow liquid GAP was obtained after washing with water and drying. After analysis, the product number average molecular weight Mn=674; hydroxyl value: 82.7mgKOH / g; N content: 32.04%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com