Rapid-curing GAP-based explosive

A rapid curing and explosive technology, applied in the direction of explosives, explosives processing equipment, non-explosive/non-thermal agent components, etc., can solve the problems of low curing rate, long curing time, and affecting the performance of cured products, so as to achieve low viscosity of the slurry, The effect of short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

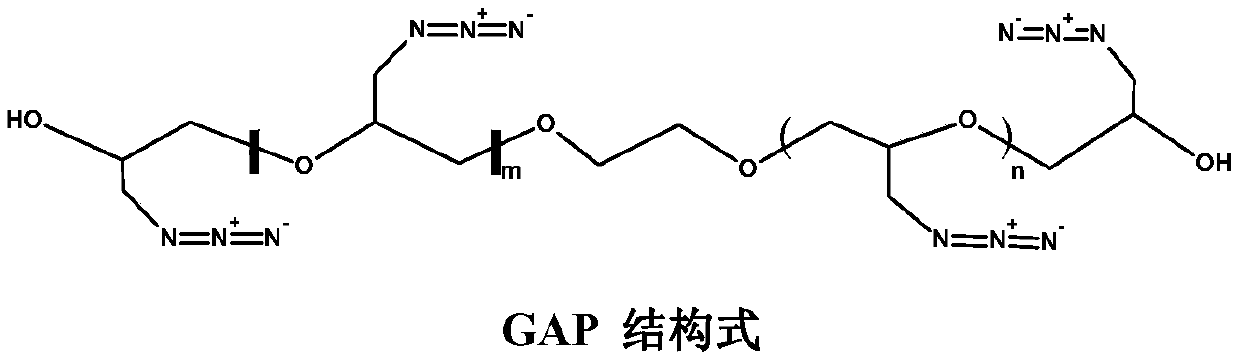

Image

Examples

Embodiment 1

[0015] The present invention is implemented with reference to the following mass percentage composition: 11.11% GAP, 1.38% dipropynyl succinate, 5.50% glyceryl triacetate, 30.00% RDX, 30.00% AP, AL powder 22.00%, triphenylbismuth 0.01 %. Wherein the number average molecular weight of GAP is 3698g / mol, and the N content in GAP is 41.72%.

[0016] Preparation:

[0017] (1) Syrup preparation

[0018] Weigh 55g glyceryl triacetate and place it in a rotary mixer, let stand at 60°C for 10min, add 111.1gGAP, stir in vacuum for 20min, add 300gRDX and stir for 5min, add 300gAP and stir for 5min, add 220g AL powder and stir in vacuum for 60min, add 13.8g butane Acid dipropynyl alcohol ester and 0.1 g triphenyl bismuth were stirred for 15 min to form a uniformly mixed syrup.

[0019] (2) sample preparation

[0020] The slurry was poured into the mold by the vacuum casting process, and the curing time was tested when the hardness remained constant at 60°C, and the performance test was...

Embodiment 2

[0022] The present invention is implemented with reference to the following mass percentage composition: 11.45% GAP, 1.14% dipropynyl succinate, 5.50% glyceryl triacetate, 30.00% RDX, 30.00% AP, AL powder 21.90%, triphenylbismuth 0.01 %. Wherein the number average molecular weight of GAP is 3698g / mol, and the N content in GAP is 41.72%.

[0023] Preparation:

[0024] (1) Syrup preparation

[0025] Weigh 55g glycerol triacetate and place it in a rotary mixer, let stand at 60°C for 10min, add 114.5gGAP, stir in vacuum for 20min, add 300gRDX and stir for 5min, add 300gAP and stir for 5min, add 219gAL powder and stir in vacuum for 60min, add 11.4g butane Acid dipropynyl alcohol ester and 0.1 g triphenyl bismuth were stirred for 15 min to form a uniformly mixed syrup.

[0026] (2) sample preparation

[0027] The slurry was poured into the mold by the vacuum casting process, and the curing time was tested when the hardness remained constant at 60°C, and the performance test was ...

Embodiment 3

[0029] The present invention is implemented with reference to the following mass percentage composition: 11.30% GAP, 1.25% dipropynyl succinate, 5.50% triacetin, 30.00% RDX, 30.00% AP, AL powder 21.94%, triphenylbismuth 0.01 %. Wherein the number average molecular weight of GAP is 3698g / mol, and the N content in GAP is 41.72%.

[0030] Preparation:

[0031] (1) Syrup preparation

[0032] Weigh 55g glycerol triacetate and put it in a rotary mixer, let stand at 60°C for 10min, add 113gGAP, stir in vacuum for 20min, add 300gRDX and stir for 5min, add 300gAP and stir for 5min, add 219.4gAL powder and vacuum stir for 60min, add 12.5g butane Acid dipropynyl alcohol ester and 0.1 g triphenyl bismuth were stirred for 15 min to form a uniformly mixed syrup.

[0033] (2) sample preparation

[0034] The slurry was poured into the mold by the vacuum casting process, and the curing time was tested when the hardness remained unchanged at 60°C, and the performance test was carried out. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com