A preparation method of polyazide glycidyl ether modified micro-nano zirconium composite particles

A technology of glycidyl ether and composite particles, which is applied in the production of compressed gas, attacking equipment, etc., can solve the problems of high electrostatic spark sensitivity, reduced electrostatic spark sensitivity, dust explosion, etc., and achieves improved safety performance and reduced electrostatic spark sensitivity. , the effect of gas cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

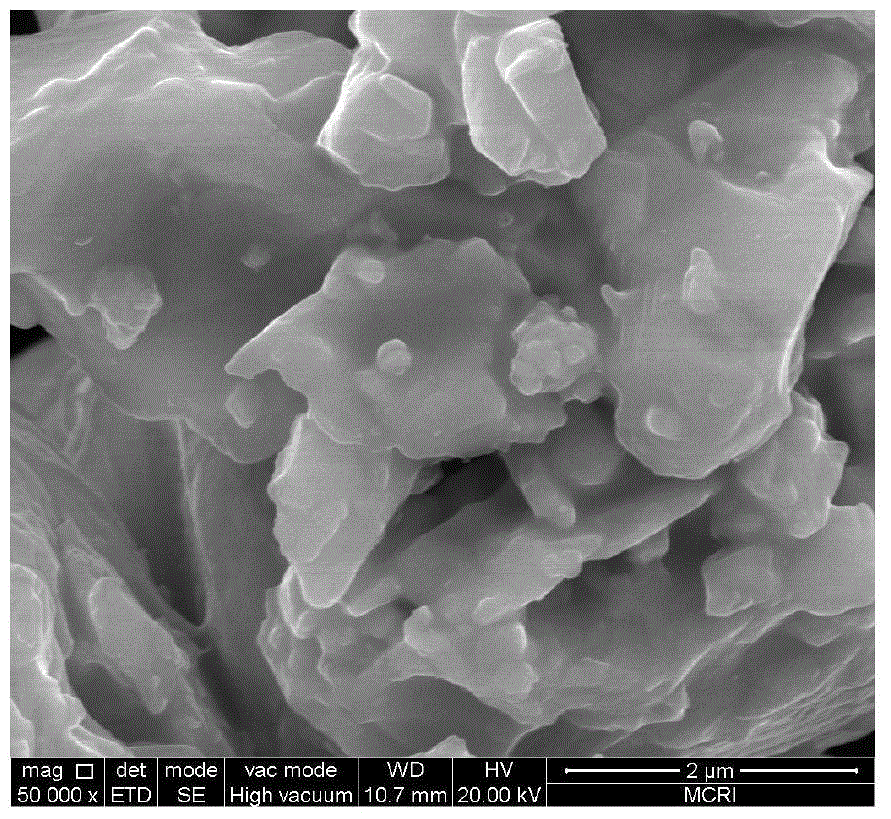

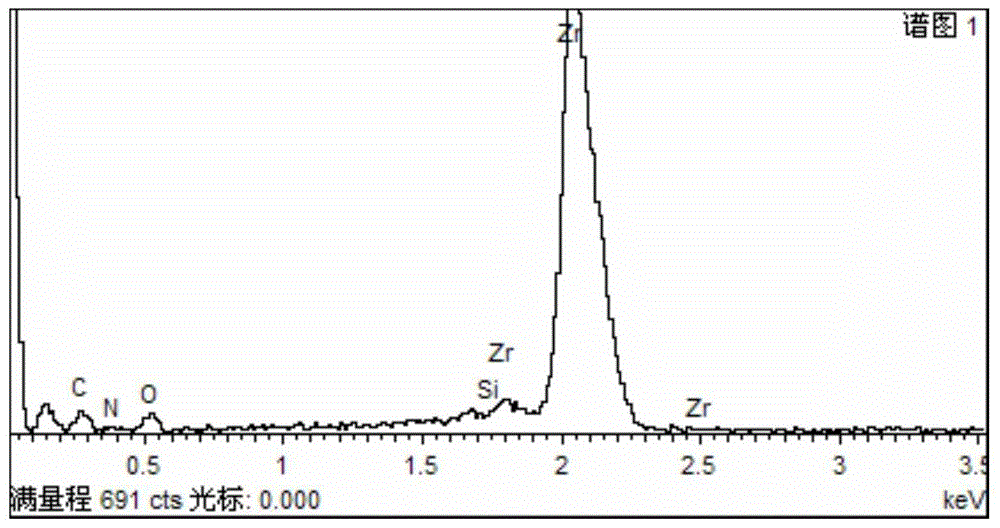

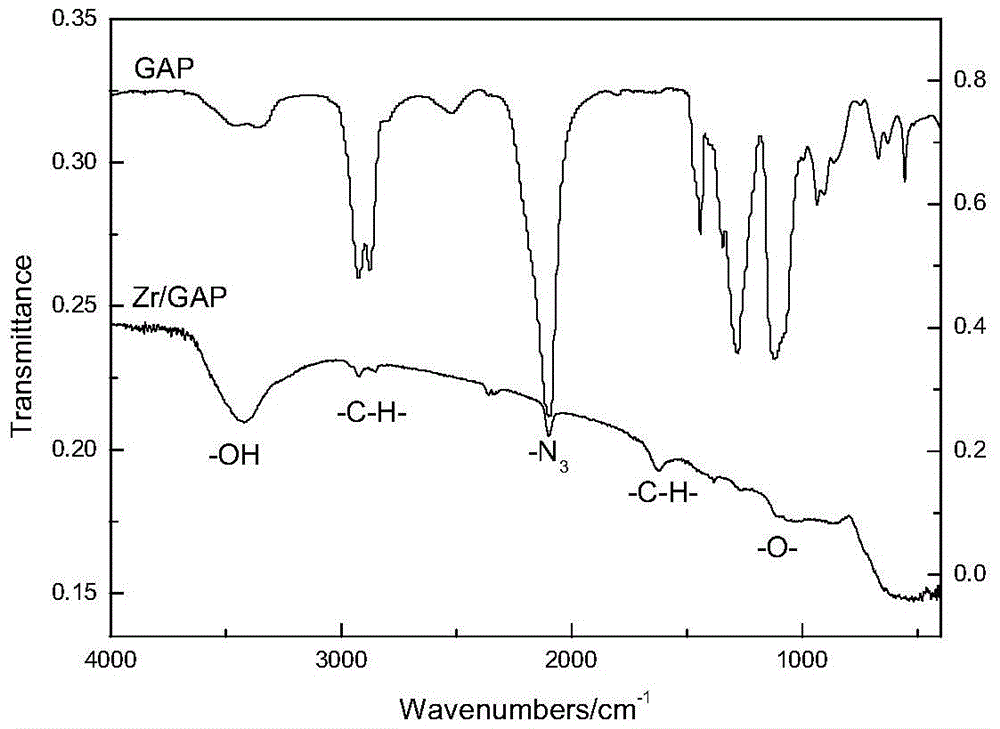

[0031] Weigh 5.0g of zirconium powder with an average particle size of 20μm, add 90mL of absolute ethanol and 10mL of water, ultrasonically disperse for 30min to disperse the zirconium powder evenly, then add 0.25g of silane coupling agent γ-aminopropyltriethoxysilane into the system, disperse and stir at 60°C for 2 hours, let stand, centrifuge, wash and dry in a vacuum oven for 12 hours to obtain pretreated zirconium powder.

[0032] Weigh 1.0 g of glycidyl azide (GAP) in 500 mL of acetone solution and dissolve it completely with ultrasonic waves to prepare a 2.0 g / L GAP solution.

[0033] Weigh 1.0g of pretreated zirconium powder and 125mL of cyclohexane into a three-necked flask, stir ultrasonically for 20min, and after the dispersion is even, slowly drop in 25mL of the above-mentioned GAP with a constant pressure dropping funnel at a rate of 1-2 drops / s. The solution was stirred for 4 hours after the dropwise addition, and the temperature of the reaction process was contro...

Embodiment 2

[0036] Weigh 5.0g of zirconium powder with an average particle size of 80nm, add 90mL of absolute ethanol and 10mL of water, ultrasonically disperse for 30min to disperse the zirconium powder evenly, then add 0.25g of silane coupling agent γ-glycidyl etheroxypropyl trimethoxy Add silane to the system, disperse and stir at 60°C for 2 hours, let stand, centrifuge, wash and dry in a vacuum oven for 12 hours to obtain pretreated zirconium powder.

[0037] Weigh 2.5g polyazide glycidyl ether (GAP) in 500mL acetone solution and dissolve it completely with ultrasonic waves to prepare 5.0g / L GAP solution.

[0038]Weigh 1.0g of pretreated zirconium powder and 75mL of cyclohexane into a three-necked flask, and stir ultrasonically for 20min until they are evenly dispersed, then slowly drop in 15mL of the above-mentioned GAP with a constant pressure dropping funnel at a rate of 1-2 drops / s. The solution was stirred for 6 hours after the dropwise addition, and the temperature of the reacti...

Embodiment 3

[0040] Weigh 5.0g of zirconium powder with an average particle size of 40nm, add 90mL of absolute ethanol and 10mL of water, and ultrasonically disperse for 30min to disperse the zirconium powder evenly, then add 0.25g of silane coupling agent γ-(methacryloyloxy)propane Add trimethoxysilane to the system, disperse and stir at 60°C for 2 hours, let stand, centrifuge, wash and dry in a vacuum oven for 12 hours to obtain pretreated zirconium powder.

[0041] Weigh 1.5g polyazide glycidyl ether (GAP) in 500mL acetone solution and dissolve it completely with ultrasonic wave to prepare 3.0g / L GAP solution.

[0042] Weigh 1.0g of pretreated zirconium powder and 45mL of cyclohexane into a three-necked flask, and stir ultrasonically for 20min until uniform dispersion, then slowly drop in 15mL of the above-mentioned GAP with a constant pressure dropping funnel at a rate of 1-2 drops / s. The solution was stirred for 6 hours after the dropwise addition, and the temperature of the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com