Round chaff type large-scale high-temperature heat flux sensor

A heat flow sensor, a large-scale technology, applied in the direction of electrical radiation detectors, etc., can solve the problems such as the inability to meet the requirements of long-term work, the difficulty of maintaining a constant temperature of the heat sink body, and the inability to achieve large-scale measurement, so as to reduce the transfer and avoid direct Contact, the effect of slowing the rate of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

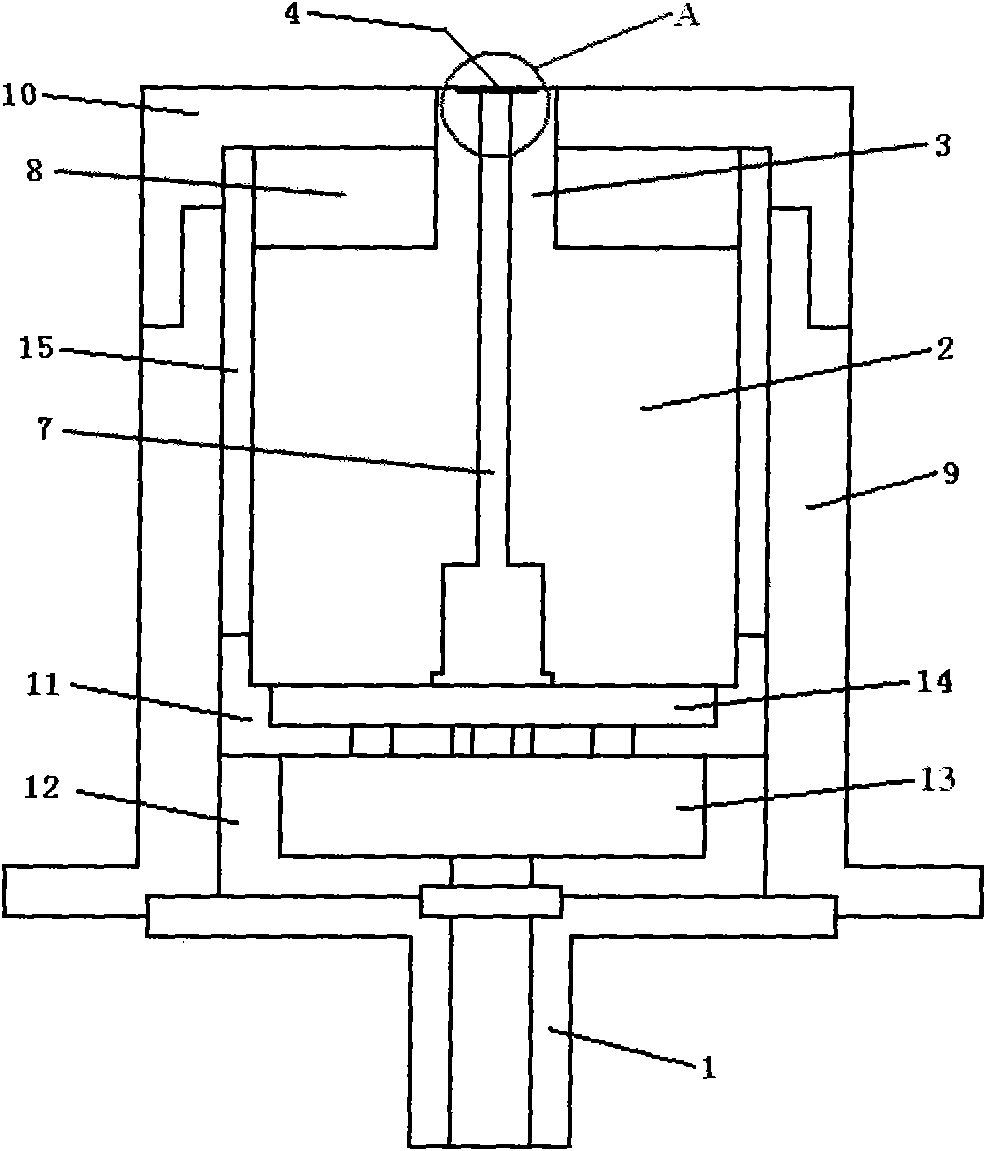

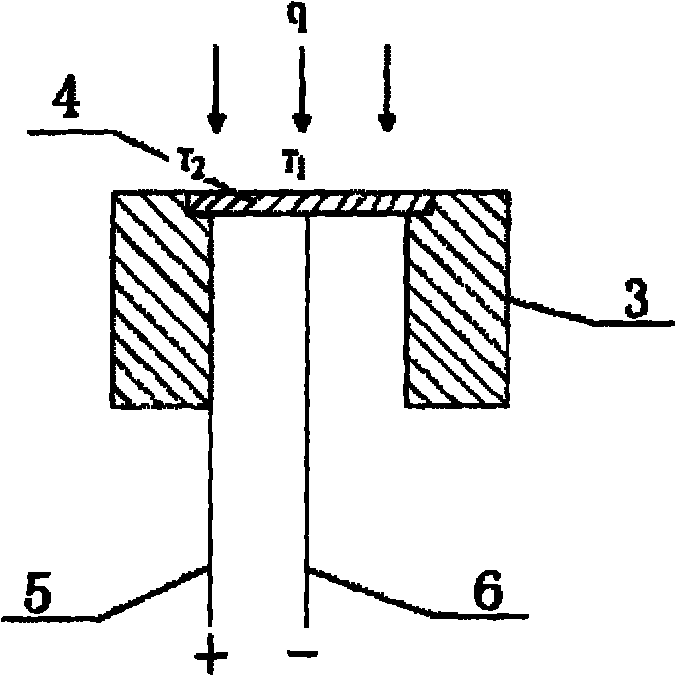

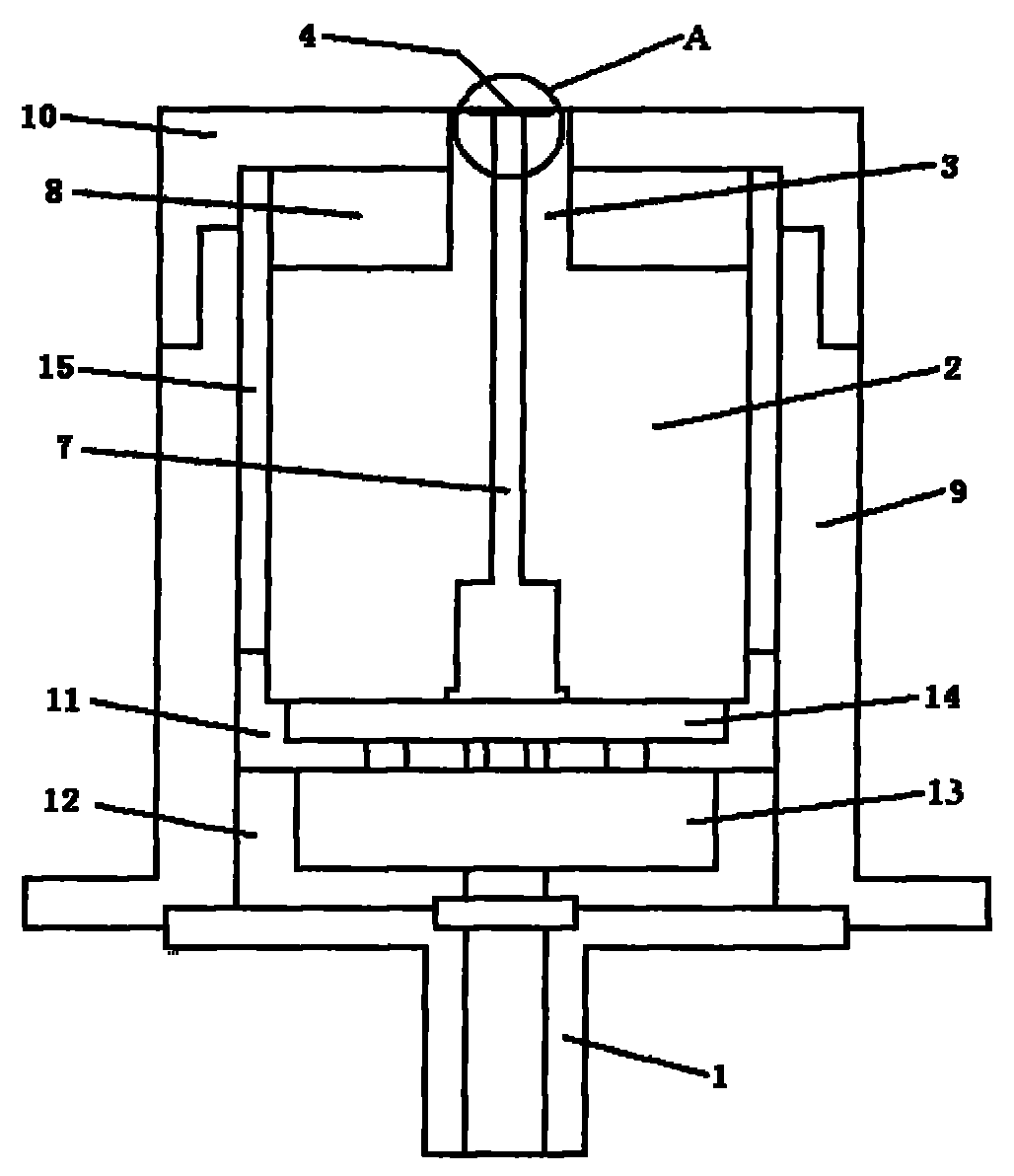

[0014] Such as figure 1 , 2 As shown, the round foil type large-range high-temperature heat flow sensor includes a shell equipped with a bottom cover 1 and a heat sink body placed in the shell. The heat sink body is composed of a main body 2 and a columnar boss 3 arranged at the top center of the main body 2. The top of the outer shell is provided with a through hole for inserting the cylindrical boss 3 on the top of the heat sink body. A round foil 4 is embedded on the cylindrical boss 3 on the top of the heat sink body. The center and edges of the round foil 4 are respectively welded with leads 5, 6. The round foil 4 and the two leads 5 and 6 constitute a thermocouple, and the heat sink body 2 and its top cylindrical boss 3 penetrate through with a channel 7 for leading the leads 5 and 6 out, and the top cylindrical boss of the heat sink body 3 The outer jacket is provided with an insulating ring 8, and the insulating ring 8 is placed between the heat sink body 2 and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com