Method for measuring reaction completeness of powdered aluminium during aluminized explosive explosion process

A technology with complete reaction and measurement method, applied in the direction of material explosiveness, etc., can solve the problems of high test cost, no time scale for measurement results, and inability to characterize the reaction process of aluminum powder in aluminum-containing explosives, so as to achieve the effect of rapid measurement process measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

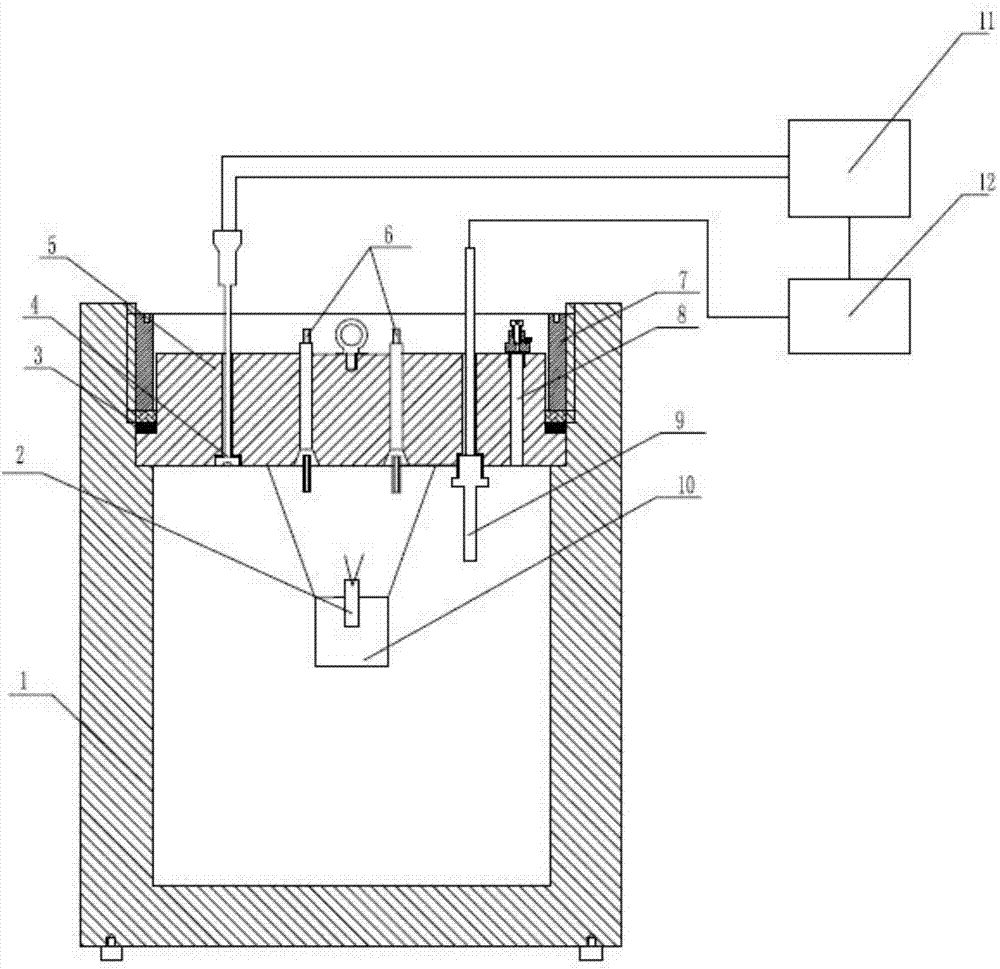

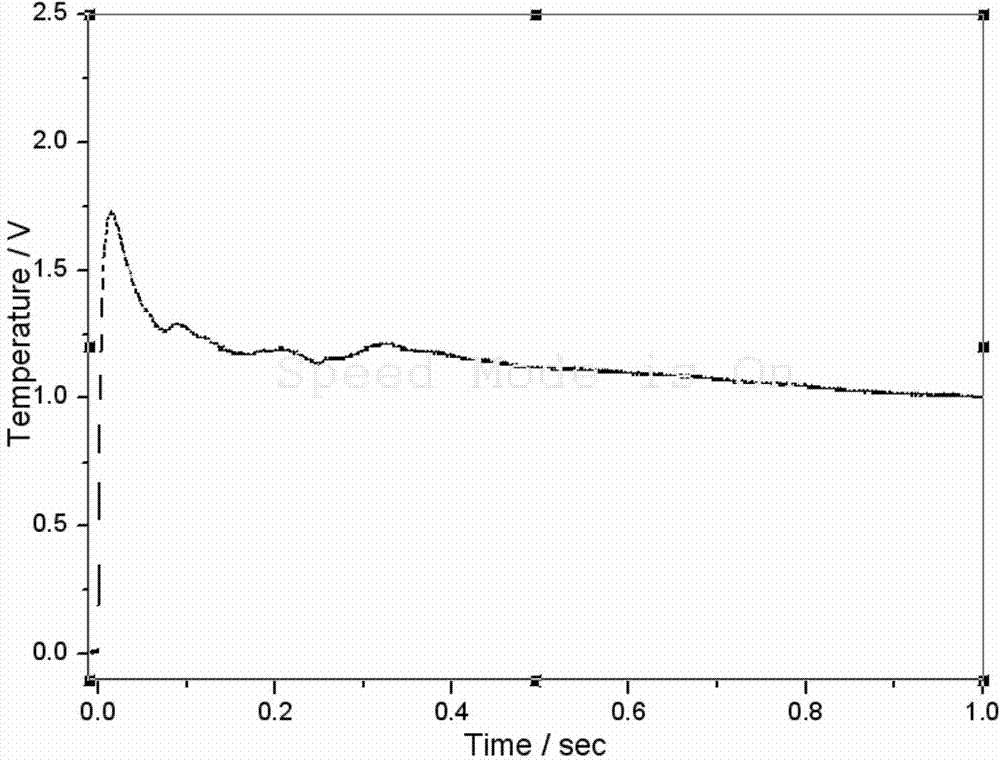

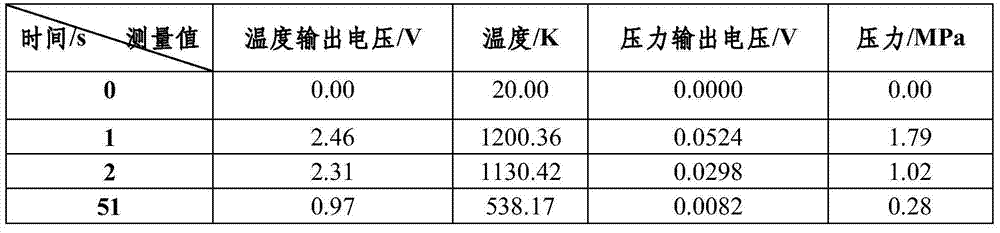

[0036] Following the technical scheme of the present invention, the closed explosive in this embodiment is a steel cylindrical projectile, with a height of 400mm, an outer diameter of 270mm, an inner diameter of 188mm, a wall thickness of 41mm, and an internal volume of 5.8L, and the interior of the projectile is equipped with Lining protective layer. The test condition is vacuum, the size of the sample to be tested is Φ25mm*25g, the resistance of the detonator is 1.0Ω; the temperature sensor adopts high-pressure tungsten rhenium thermocouple, the sensitive surface is 4cm from the center of the sample to be tested, and the magnification is 100 times; the pressure sensor adopts The ultra-high temperature silicon piezoresistive sensor is 20cm away from the center of the sample to be tested. The charge amplifier adopts the YE3818 dynamic strain gauge. The test data is collected by GEN5i of HBM company, the collection frequency is 10K / s, and the collection period is 51s. The formu...

Embodiment 2

[0040] This example gives the same explosive formula as that of Example 1, and the measuring instruments and measuring methods used are exactly the same. The difference is that the aluminum powder used in the explosive formula of this example has different specifications. The sample 1 is 4μ, the sample 2 is 13μ, the sample 3 is 26μ, the sample 4 is a sheet, and the sample 8 is an inert material. The parameter curve of the explosion process is obtained, and the temperature and the converted temperature are collected and converted 1 second after the explosion. The pressure value is shown in Table 2.

[0041] Table 2 1 second measurement results of aluminum-containing explosives with different specifications of aluminum powder after explosion

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com