Tobacco combustion heat measurement apparatus

A technology of measuring devices and combustion devices, which is applied in the direction of material heat development, etc., can solve problems such as difficult to accurately measure tobacco combustion heat, poor repeatability, and inability to simulate the oxygen-poor combustion environment of cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

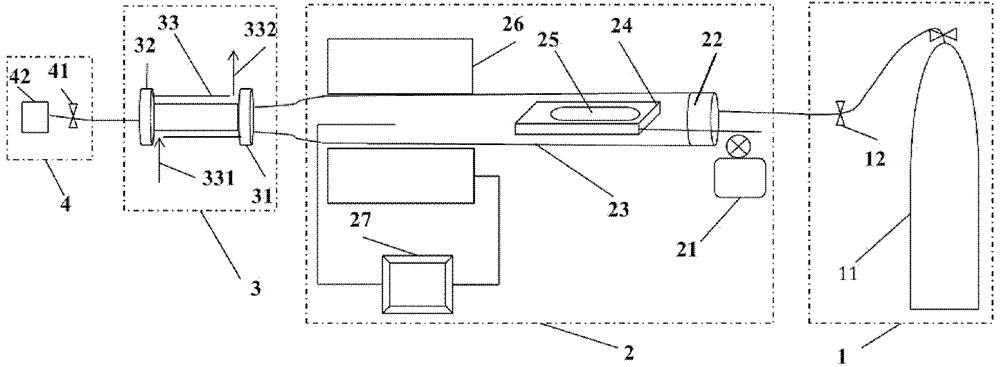

[0031] Embodiment 1: as figure 1 As shown, the device disclosed in the present invention includes a gas supply device 1 , a combustion device 2 , a filter device 3 and an analysis device 4 . The combustion device 2 is used to provide a stable supply of tobacco samples and a stable temperature field; the air supply device 1 is used to provide stable air with an adjustable flow rate for the combustion device 2; the filter device 3 is directly connected to the air outlet of the combustion device for purification The gas produced by combustion avoids pollution to the analysis device 4; the analysis device 4 is connected after the filter device 3, and is used to test the volume content of oxygen in the effluent gas.

[0032] When testing the heat of combustion of cigarettes, according to the theoretically calculated air supply rate and tobacco sample supply rate, set relevant parameters, by controlling the supply rate of tobacco samples in the combustion device 2 and the gas flow r...

Embodiment 2

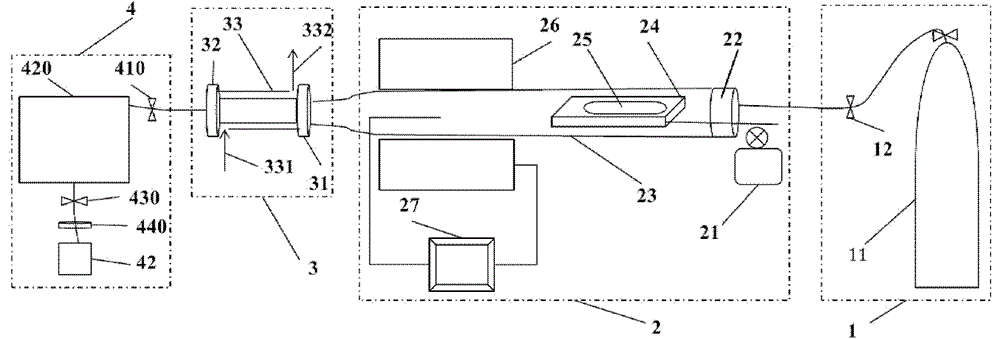

[0035] Embodiment 2: as image 3 As shown, the off-line measurement device of this embodiment includes a gas supply device 1 , a combustion device 2 , a filter device 3 and an analysis device 4 . Wherein, the specific structure and connection sequence of the combustion device 2 , the air supply device 1 and the filter device 3 are the same as those in Embodiment 1, and will not be repeated here.

[0036] Described analytical device 4 comprises the gas collection bag 420 that communicates with second stage filter through the first pipeline, and the oxygen analyzer 42 that communicates with gas collection bag through the second pipeline; The control valve 410 is provided with a second control valve 430 and a purifier 440 on the second pipeline. The gas collection bag 420 is used to collect gas from the combustion device 2 . The purification device is used to remove the particles and moisture in the gas in the gas bag to avoid pollution to the oxygen analyzer.

[0037] When te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com