Comprehensive testing method of optical performance of deep ultraviolet optical element

A technology of deep ultraviolet and comprehensive testing, which is applied in the direction of testing optical properties, etc., can solve the problems of simultaneous and in-situ measurement of fluorescence spectrum, and the inability to simultaneously measure the change of H2 content in deep ultraviolet optical components, so as to save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

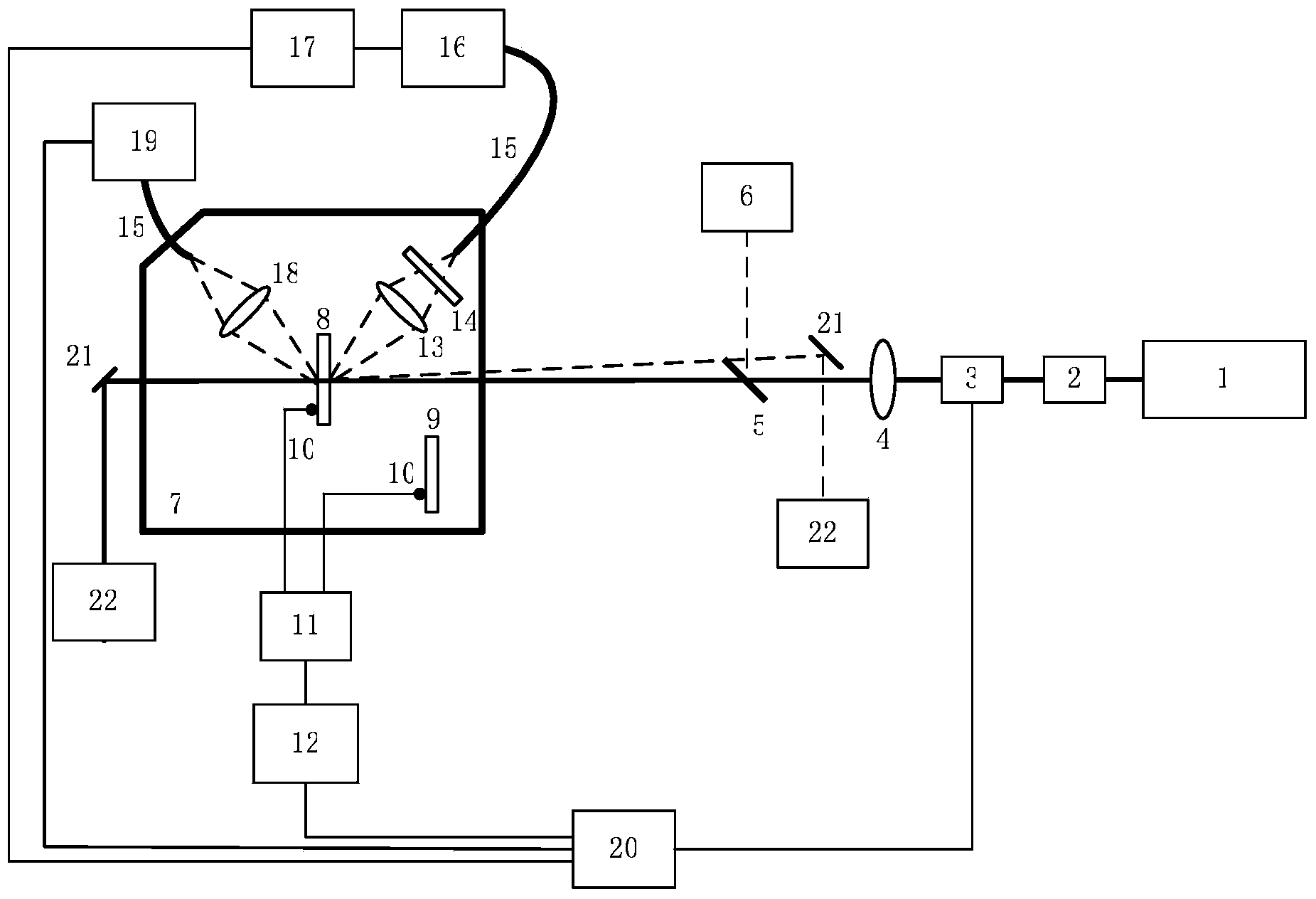

[0027] Such as figure 1 As shown, the present invention uses a coupling optical fiber to couple and transmit a comprehensive test device for Raman scattered light, which consists of a narrow linewidth deep ultraviolet laser light source 1, a beam shaping system 2, an electronically controlled variable optical attenuator 3, a focusing lens 4, and an electric optical shutter 5 , laser power meter 6, adiabatic sample chamber 7, tested sample fixture and tested deep ultraviolet optical element sample 8, reference sample fixture and reference sample 9, sensitive temperature detection unit 10, bridge amplifier circuit 11, A / D converter 12. Fluorescence collection optical system 13, narrow-band optical filter 14, coupling optical fiber 15, monochromator 16, fluorescence photodetection device 17, Raman scattered light collection optical system 18, high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com