Preparation method of large-size ITO target material

A large-scale, target technology, applied in the field of transparent conductive film targets, to achieve the effect of less initial investment and small size restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

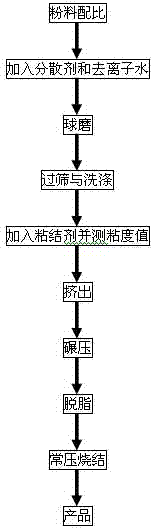

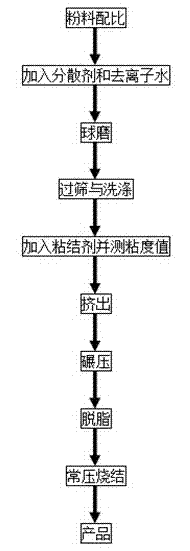

Method used

Image

Examples

Embodiment 1

[0024] (1) Take ITO powder, mix different nano-level ITO powder in proportion (weight percentage), then add 10wt% deionized water of ITO powder and 2wt% dispersant polyethylene glycol (PEG), and then pass Ball mill for 4 hours to pass through a 200-mesh sieve, and finally wash twice with deionized water; the nanoscale of ITO powder is divided into 20nm, 40nm, and 90nm, and the proportion of ingredients can be 20nm:40nm:90nm=4:2: 1, the IITO powders are commercially available with a purity of more than 99.995wt%.

[0025] (2) After filtering the washed ITO powder prepared in step (1), add 8wt% binder polyvinyl alcohol (PVA) of ITO powder dry material, and stir for 1 hour;

[0026] (3) Extrude the mixture obtained in step (2) into a sheet under a pressure of 200MPa, and then repeatedly roll it twice under a rolling pressure of 0.1Pa;

[0027] (4) Place the billet that has passed through step (3) at a temperature of 250°C and keep it warm for 6 hours to degrease;

[0028] (5) S...

Embodiment 2

[0030] (1) Take ITO powder, mix different nano-scale ITO powder in proportion (weight percentage), then add 30wt% deionized water of ITO powder and 10wt% dispersant polyethylene glycol (PEG), and then pass Ball mill for 3 hours to pass through a 200-mesh sieve, and finally wash once with deionized water; the nanoscale of ITO powder is divided into 20nm, 40nm, and 80nm, and the proportion of ingredients can be 20nm:40nm:80nm=3:2: 1, the IITO powders are commercially available with a purity of more than 99.995wt%.

[0031] (2) After filtering the washed ITO powder prepared in step (1), add 2wt% binder polyvinyl alcohol (PVA) of ITO powder dry material, and stir for 2 hours;

[0032] (3) Extrude the mixture obtained in step (2) into a sheet under a pressure of 400MPa, and then repeatedly roll it 4 times under a rolling pressure of 0.05Pa;

[0033] (4) Put the billet after step (3) in the temperature range of 300°C, keep it warm for 3 hours to degrease;

[0034] (5) Send the bla...

Embodiment 3

[0036] (1) Take ITO powder, mix different nano-scale ITO powder in proportion (weight percentage), then add 5wt% deionized water of ITO powder and 1wt% dispersant polyethylene glycol (PEG), and pass Ball mill for 15 hours to pass through a 200-mesh sieve, and finally wash with deionized water for 3 times; the nanoscale of ITO powder is divided into 20nm, 40nm, and 60nm, and the proportion of ingredients can be 20nm:40nm:60nm=2:2: 1, the IITO powder is commercially available with a purity of more than 99.995wt%.

[0037] (2) After filtering the washed ITO powder prepared in step (1), add 20wt% binder polyvinyl alcohol (PVA) of ITO powder dry material, and stir for 3 hours;

[0038] (3) Extrude the mixture obtained in step (2) into a sheet under a pressure of 600 MPa, and then repeatedly roll it 3 times under a rolling pressure of 3 Pa;

[0039] (4) Put the billet after step (3) in the temperature range of 600°C, keep it warm for 4 hours to degrease;

[0040] (5) Send the blan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com