Method capable of obtaining flexible graphene current collectors in batches

A technology of flexible graphite and current collectors, which is applied in the direction of graphene, chemical instruments and methods, electrode carriers/current collectors, etc., can solve problems such as low production efficiency, complicated processes, and complicated procedures, so as to ensure surface smoothness and process pressure Small, uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

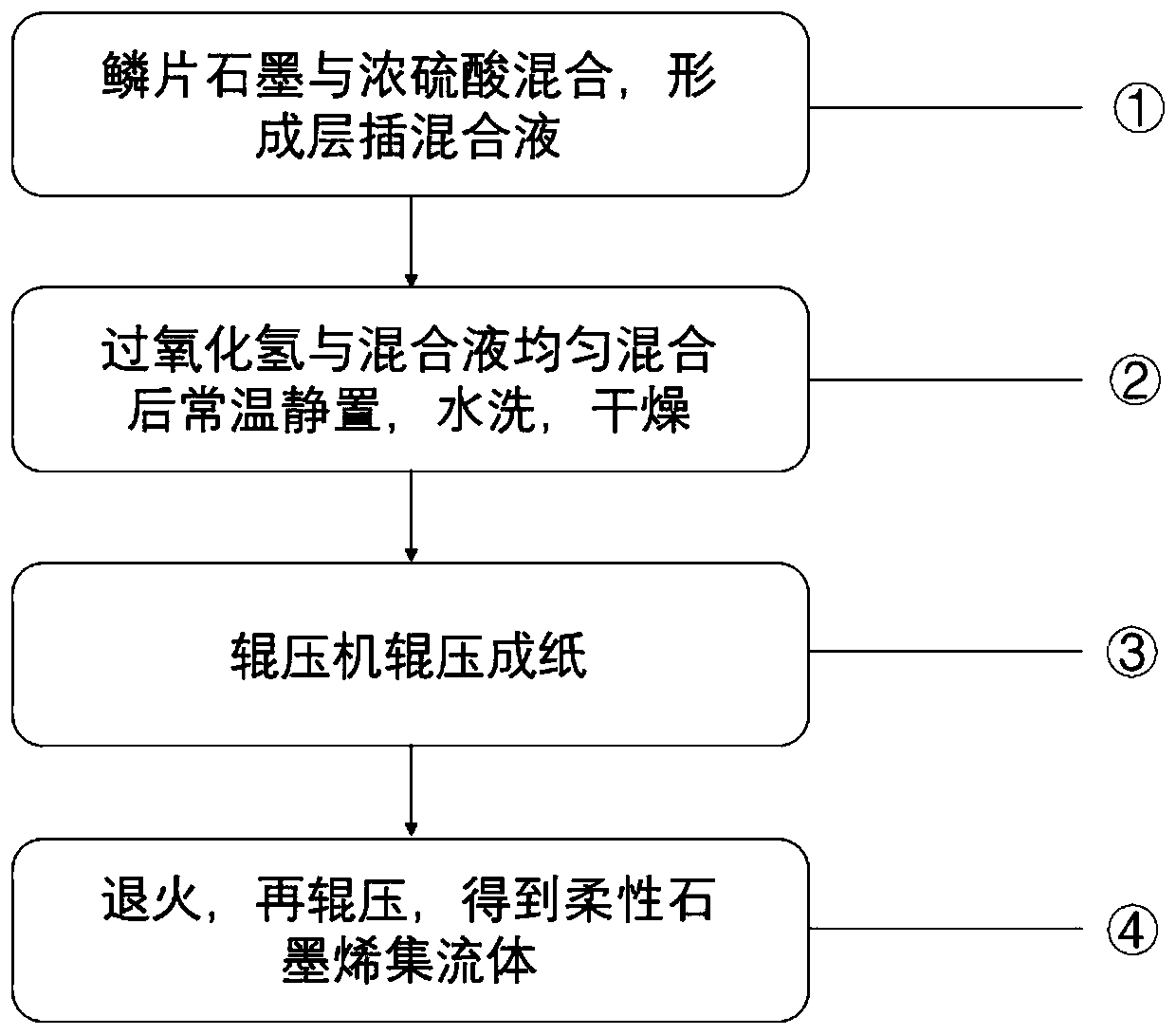

[0034] A method for preparing a flexible graphene current collector includes the following steps:

[0035] Mix 1g of 50 mesh flake graphite with 25mL of 98% concentrated sulfuric acid solution by mass percentage for 5min at a stirring rate of 100r / min, and then add 7mL of 30% mass percentage hydrogen peroxide solution at 50r / min Stir at a speed of 30min, mix well and let stand at room temperature for 6 hours to puff and peel, wash to neutrality, and dry at 80℃ for 24 hours to obtain graphene powder; the obtained graphene powder is rolled at a roller press spacing of 20μm 30s into non-self-supporting flexible graphene paper; non-self-supporting flexible graphene paper is annealed in air at 450°C for 1h, and then rolled again at a roller press spacing of 20μm for 30s to obtain the final flexible graphene paper.

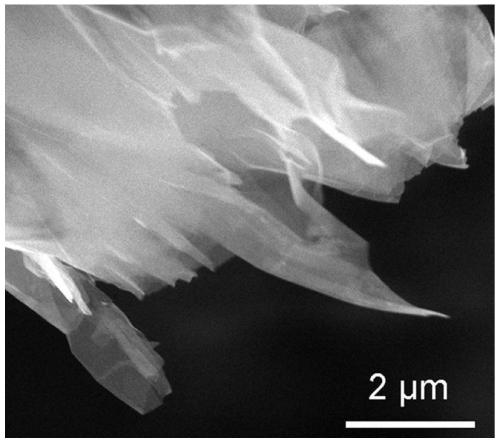

[0036] figure 2 Is the microscopic SEM image of the graphene powder obtained in Example 1, such as figure 2 As shown, it can be seen that after the original graphite is in...

Embodiment 2

[0040] A method for preparing a flexible graphene current collector includes the following steps:

[0041] Mix 1g of 200 mesh flake graphite with 15mL of 98% concentrated sulfuric acid solution for 5min at a stirring rate of 100r / min, then add 5ml of hydrogen peroxide solution with a mass percentage concentration of 30%, and stir for 30min at a speed of 50r / min After mixing uniformly, let stand at room temperature for 6 hours to puff and peel, wash to neutrality with water, and dry at 60°C for 72 hours to obtain graphene powder; the obtained graphene powder is rolled for 10 seconds at a roller press distance of 40 μm. Self-supporting flexible graphene paper; non-self-supporting flexible graphene paper is annealed in air at 450°C for 3 hours, and then rolled again for 10 seconds at a roller press distance of 40 μm to obtain the final flexible graphene paper.

[0042] The conductivity of the resulting graphene paper measured by the four-point resistance test method at room temperatur...

Embodiment 3

[0044] A method for preparing a flexible graphene current collector includes the following steps:

[0045] Stir and mix 0.2g of 50 mesh flake graphite with 5mL of concentrated sulfuric acid solution for 20min at a stirring rate of 100r / min. Then add 3ml of hydrogen peroxide solution with a mass percentage concentration of 30% and stir for 10min at a speed of 50r / min. After mixing uniformly, let stand at room temperature for 12 hours to puff and peel off. After washing to neutrality and drying at 80°C for 24 hours, graphene powder is obtained; the obtained graphene powder is rolled for 20s under a 20μm roller press distance. Supporting flexible graphene paper; non-self-supporting flexible graphene paper is annealed in air at 450°C for 3h, and then rolled again for 20s at a roller press distance of 20μm to obtain the final flexible graphene paper.

[0046] The conductivity of the obtained graphene paper measured by the four-point resistance test method at room temperature is 2.08×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com