Method for producing aluminium by colol extrusion

A manufacturing method and technology of aluminum tubes, applied in the field of cold extrusion of aluminum tubes, can solve problems such as low processing stability, low processing stability, and low processing accuracy, and achieve reduced inventory costs, reduced material costs, and stable processing high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

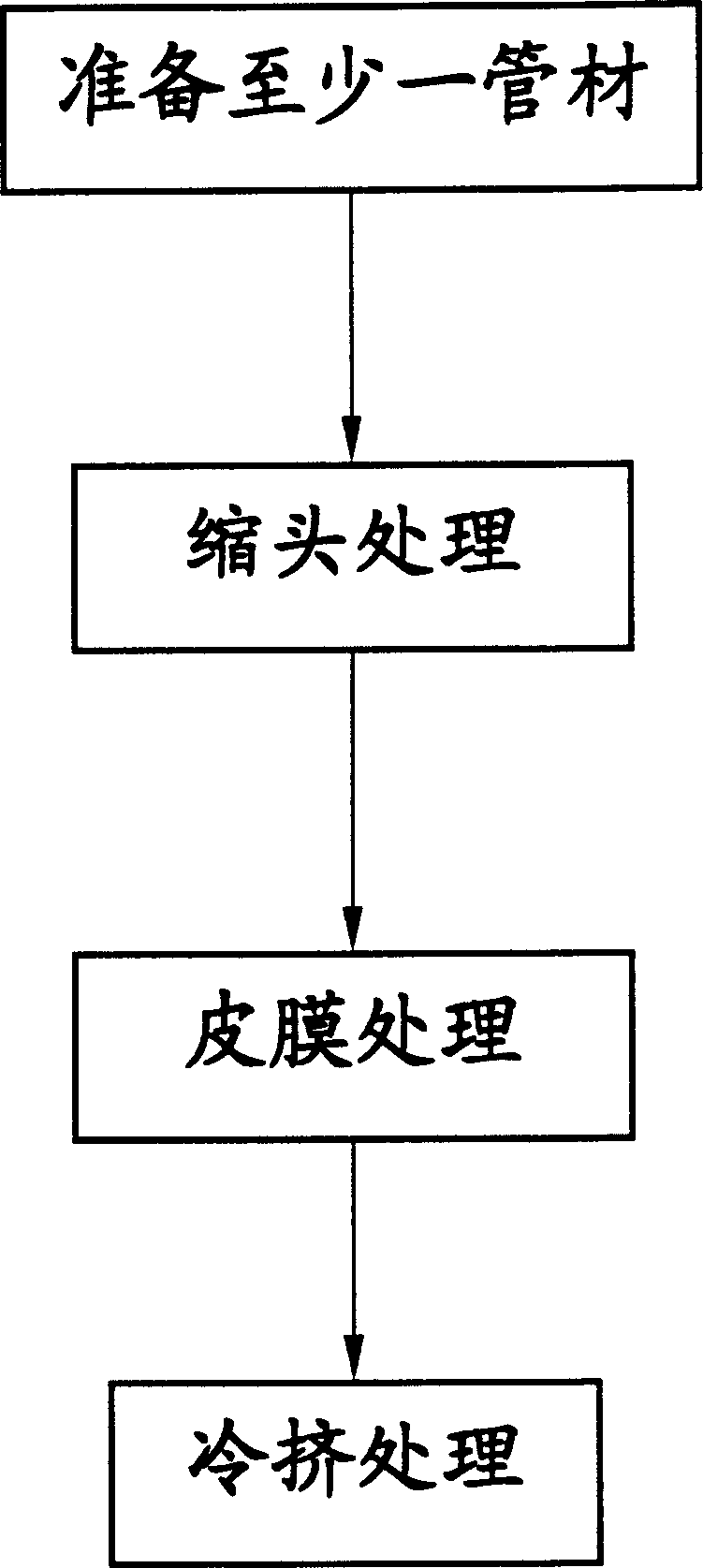

[0035] refer to figure 1 , 2 , 3, 4, a better embodiment of the present invention comprises the following steps:

[0036] 1. Prepare a pipe 10: the pipe 10 is made of heat-treated aluminum alloy, and is formed by extrusion (heated to 550° C.), and the pipe 10 has been subjected to solution treatment and aging hardening after forming.

[0037] 2. Shrinking treatment: making the diameter of one end of the pipe 10 smaller. This is a common common technology in the art, so it will not be described in detail.

[0038] 3. Film treatment: apply a lubricant on the pipe 10, in this embodiment a liquid lubricant is used.

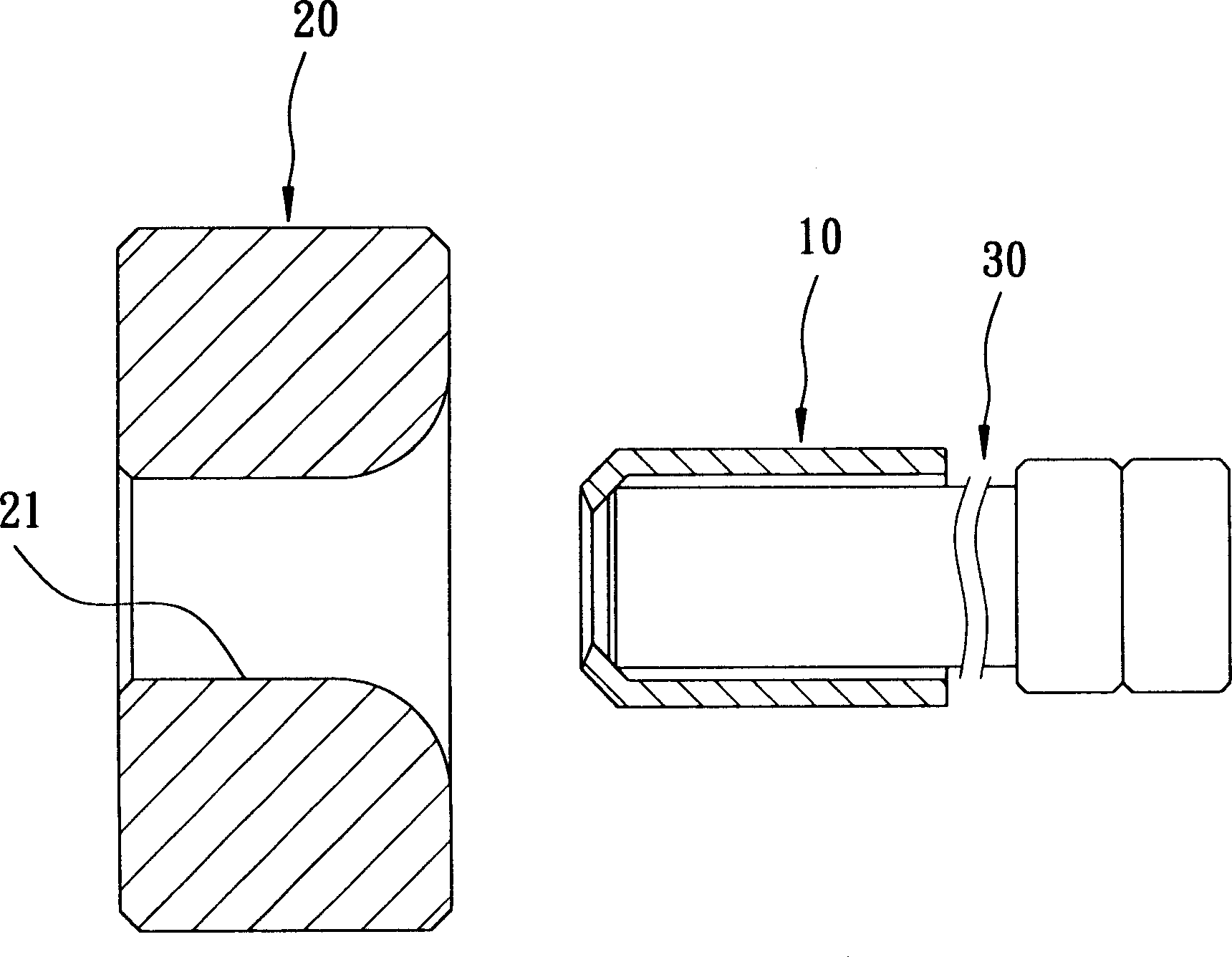

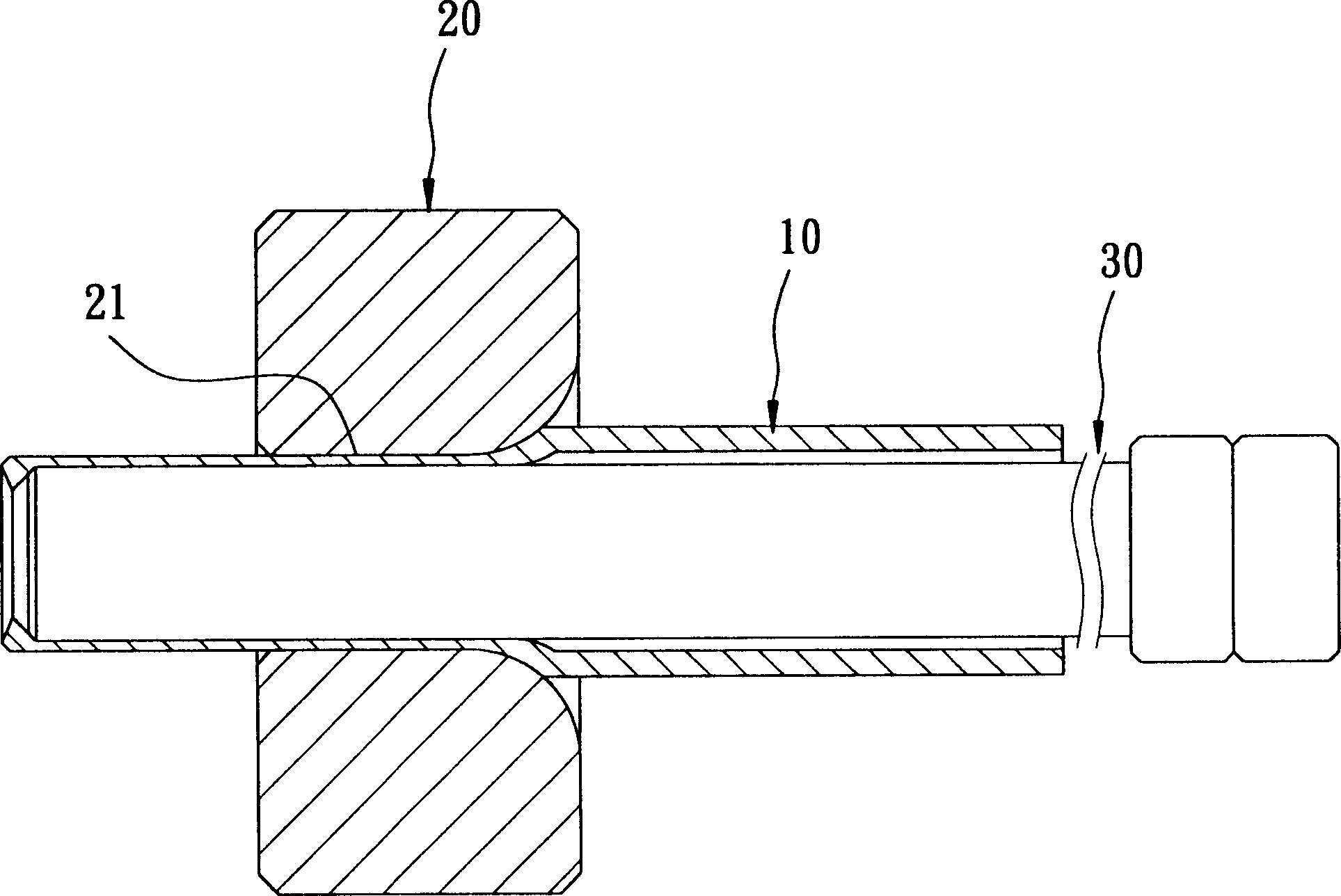

[0039] 4. Cold extrusion treatment: prepare a die 20 and a mandrel 30, and at normal temperature, make the mandrel 30 extend into the pipe 10, and push the end of the pipe 10 that has been shrunk to drive the pipe 10 through the pipe. The mold eye 21 of the eye mold 20 is so that the pipe material 10 can be formed into a required aluminum pipe 40 after demoulding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com