Magnetic reed pipe feeding machine and plug-in machine thereof

A reed tube and feeder technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of pin asymmetry, reed tube lack of positioning and deviation correction, plug-in failure, etc., and achieve the effect of not being easy to process errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to describe the technical content and structural features of the present invention in detail, further description will be given below with reference to the embodiments and the accompanying drawings.

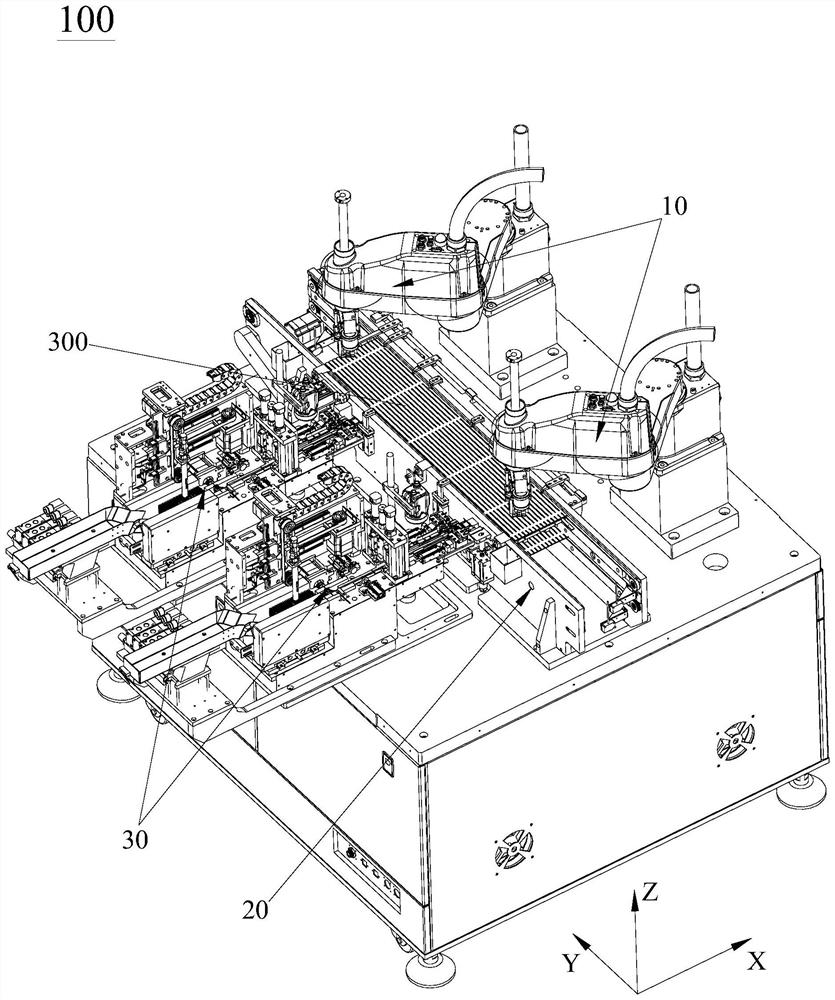

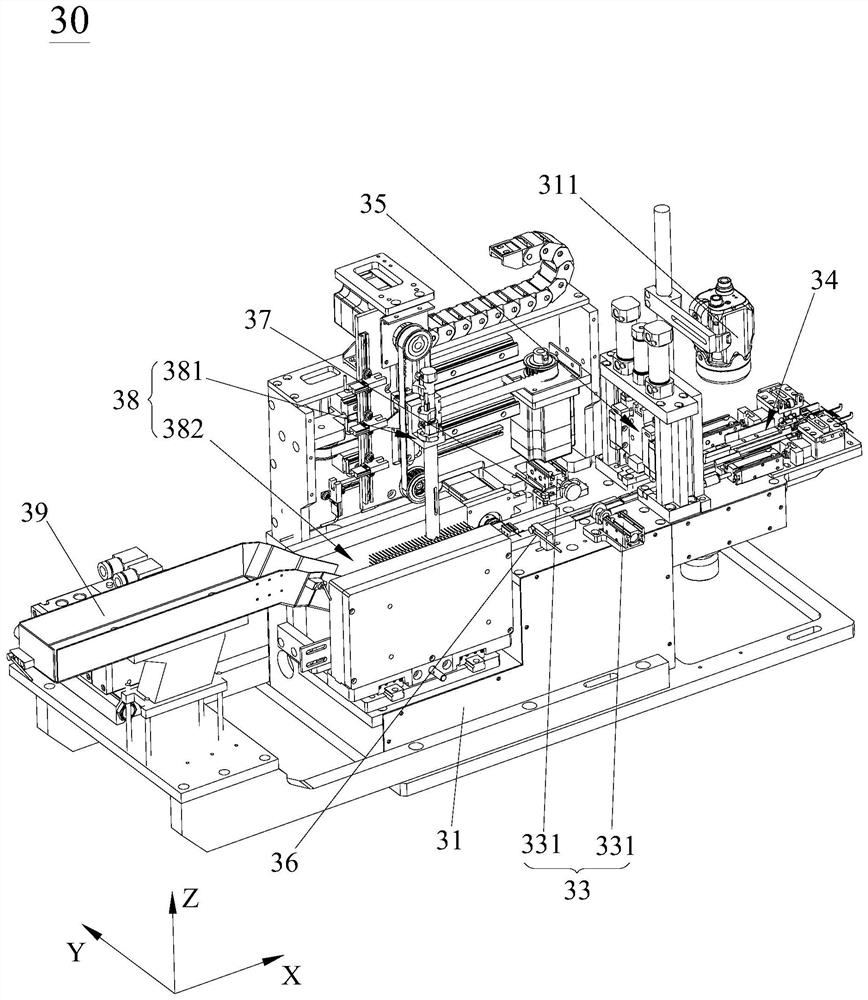

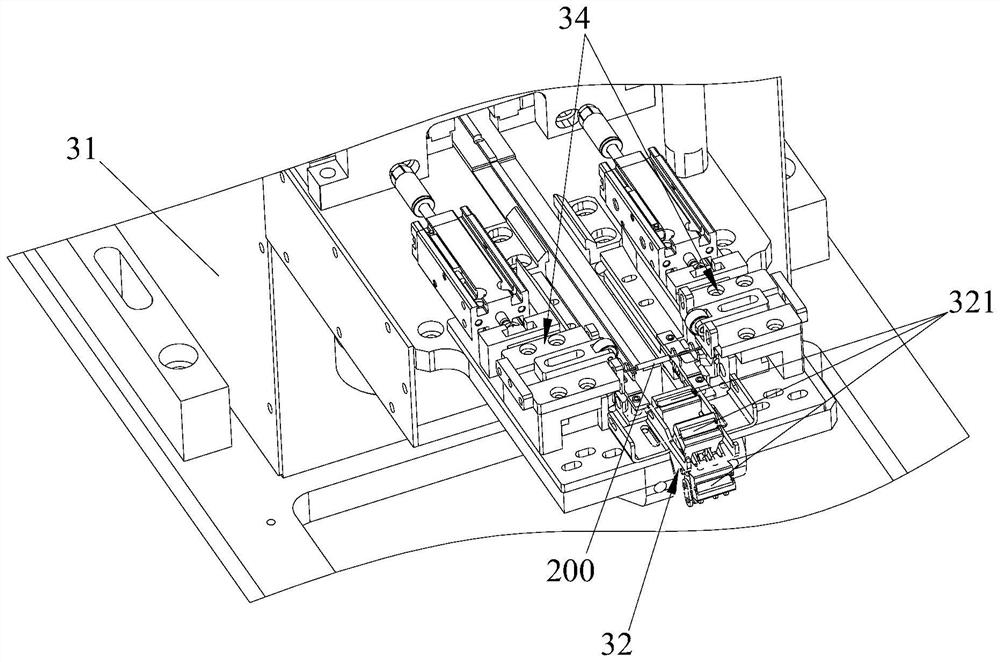

[0033] like figure 1 and figure 2 As shown, the plug-in machine 100 of the present invention includes a material-receiving plug-in robot 10 , a plate conveying line 20 and a reed tube feeder 30 . The reed tube feeder 30 is used for feeding the magnetic reed tube 200 to realize automatic feeding of the magnetic reed tube 200. The magnetic reed tube feeder 30 uses the conveying device 32 (see below for details) to transport the magnetic reed tube. The pipe 200 and the plate conveying line 20 are connected to the rear end side of the conveying device 32 . The board conveying line 20 is suitable for conveying the printed circuit board 300. The reclaiming and inserting robot 10 is installed on the side of the board conveying line 20. The taken out reed switch 200 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com