Drawer slide rail and its manufacturing method

A manufacturing method and slide rail technology, which are applied to drawers, furniture parts, household appliances, etc., can solve the problems of inapplicable manufacturing cost requirements, large width of non-fixed parts, and low stress on the installation surface, so as to reduce processing errors. , The effect of improving processing quality and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described below with reference to the accompanying drawings.

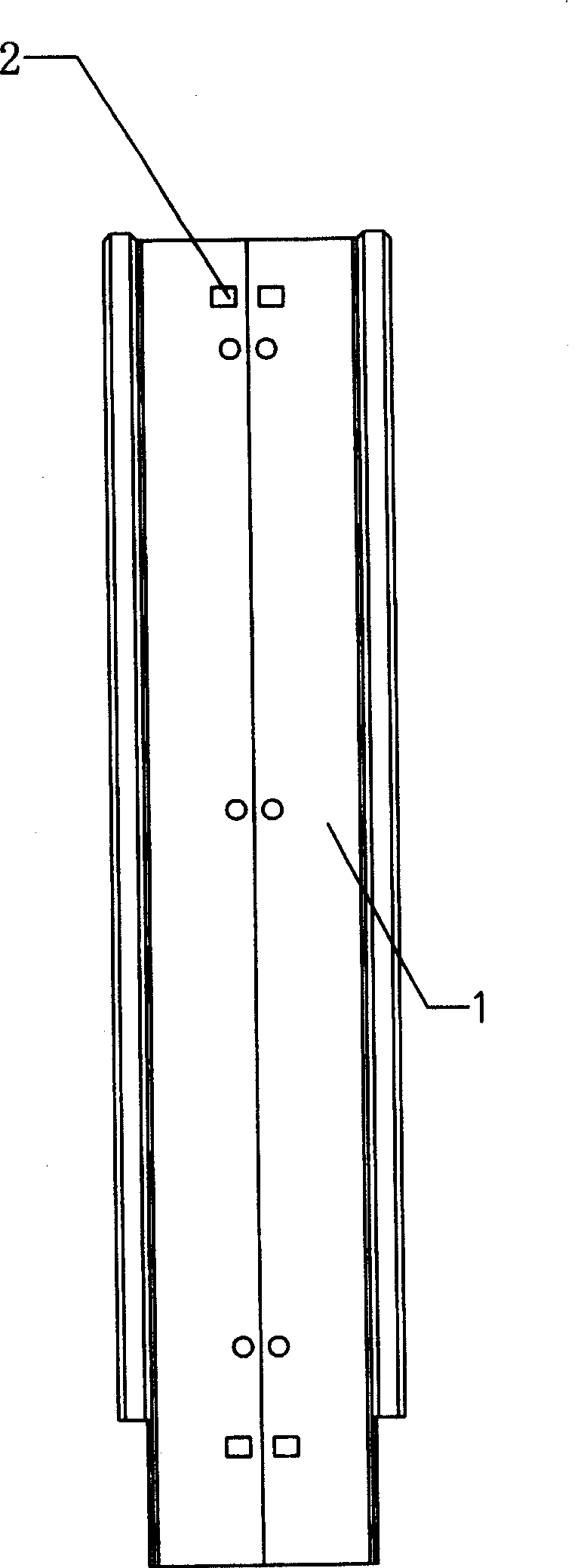

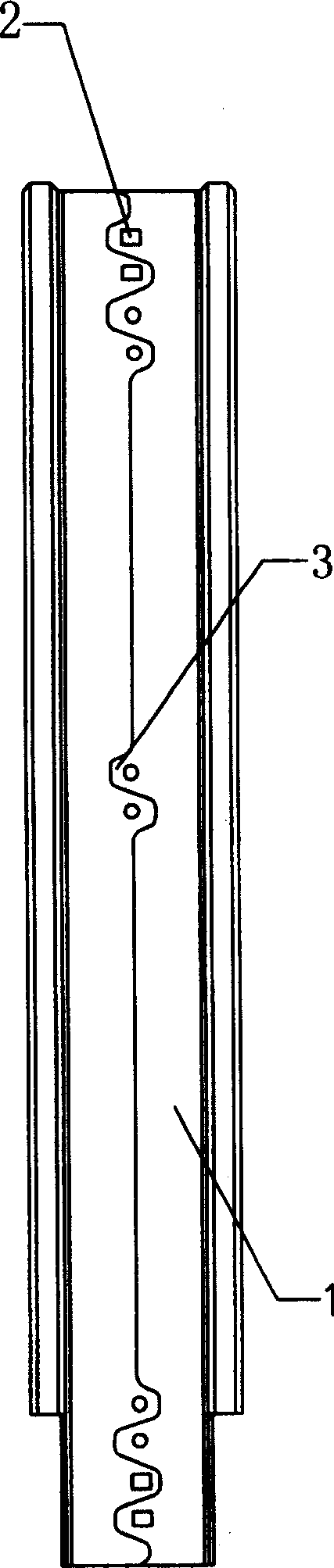

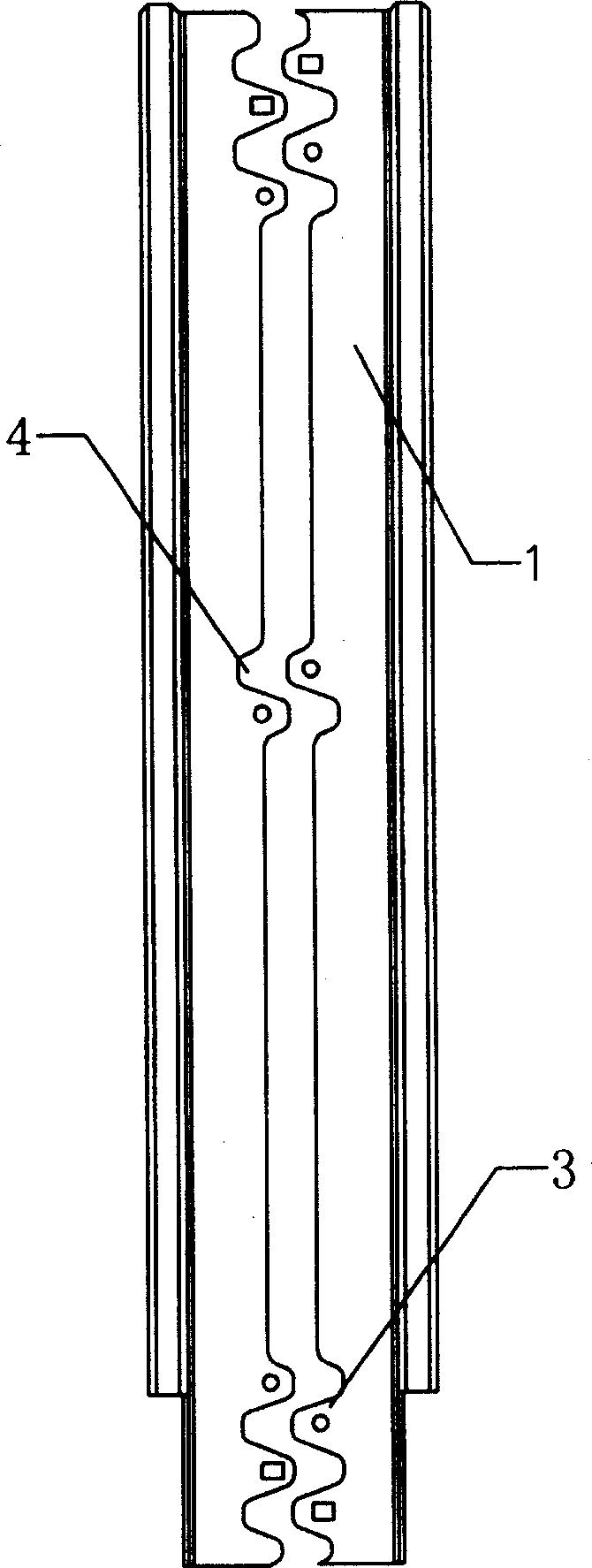

[0022] according to figure 2 As shown in Figure 3, the drawer slide rail of the present invention includes a vertical plate and two pull plates 1, the vertical plate is installed on the inside of the table, the pull plate 1 is sleeved in the vertical plate, and can slide along the vertical plate, and the other end passes through the vertical plate. Screws, nails or rivets secure the drawer. One of the pull plates 1 is provided with a lug 3 for fixing. In order to facilitate the installation of the lug 3, the edges of the lug 3 are rounded. The lug 3 is provided with a mounting hole 2 , and the other pull plate 1 is provided with a recess 4 matching with the lug 3 . In order to ensure the stability of the installation of the pull plate 1 , there are at least two sets of lugs 3 and recesses 4 on any pull plate 1 , and the lugs 3 and recesses 4 are arranged at bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com