Preparation method of high-strength and high-plasticity 304 austenitic stainless steel with low martensite content

A technology of austenitic stainless steel and 304 stainless steel, used in the field of metal material strengthening, can solve the problems of harsh process technology, low processing efficiency, and limited wide application, so as to avoid radar tracking, reduce magnetic flux leakage, and increase torsional strain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, the coarse-grained 304 austenitic stainless steel bar is subjected to small-angle cyclic reciprocating torsional deformation treatment.

[0034] Fix one end of the coarse-grained 304 austenitic stainless steel sample, and apply cyclic torsional deformation to the other end (such as figure 1 Shown), the gradient structure 304#1 sample was obtained.

[0035] The process parameters of the gradient structure 304#1 sample are selected as follows: the diameter of 304 austenitic stainless steel is 6 mm, the torsion angle amplitude is 5 degrees, the torsion speed is 9000° / min, the torsion cycle is 200 cycles, and the torsion time is about 14 seconds. The temperature is room temperature 25 degrees.

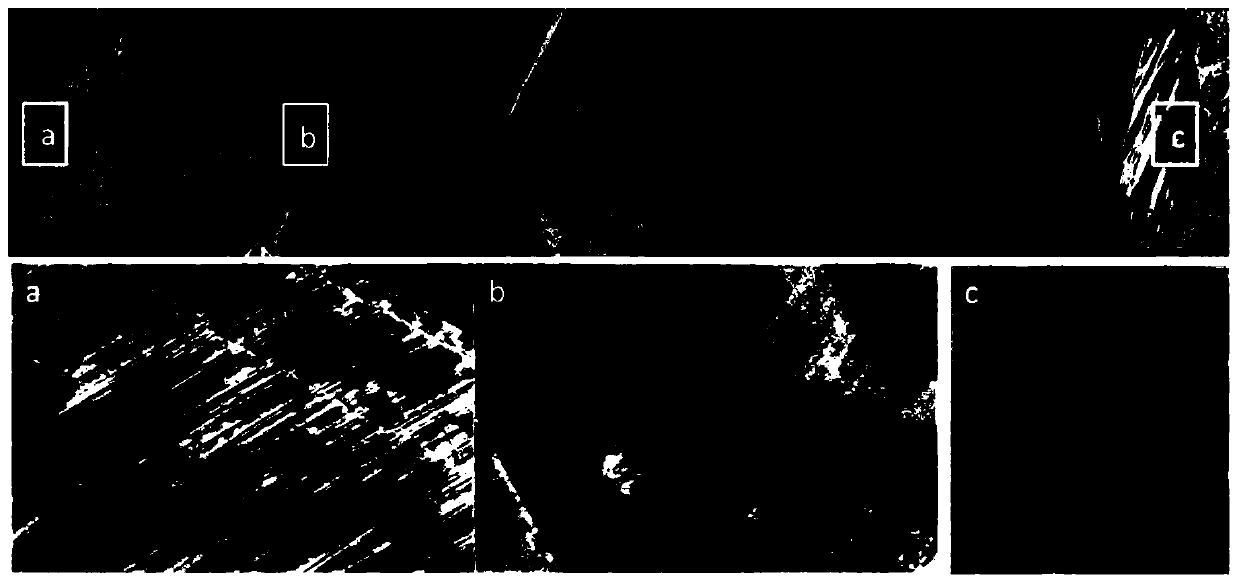

[0036] As the depth from the surface increases, the degree of deformation in the material presents a monotonically decreasing trend, forming a gradient distribution of deformation microstructure ( figure 2 ). However, the microstructure is still austenite and...

Embodiment 2

[0039] In this embodiment, a cyclic torsional deformation treatment is applied to the coarse-grained 304 austenitic stainless steel #2 sample to obtain a 304 #2 sample with a gradient structure.

[0040] The difference from Example 1 is that the process parameters of the gradient structure 304#2 sample are selected as follows: the diameter of 304 austenitic stainless steel is 6 mm, the torsion angle amplitude is 15 degrees, the torsion speed is 9000 ° / min, and the torsion cycle is 200 cycles , the torsion time is about 6 minutes, and the torsion temperature is 25 degrees at room temperature.

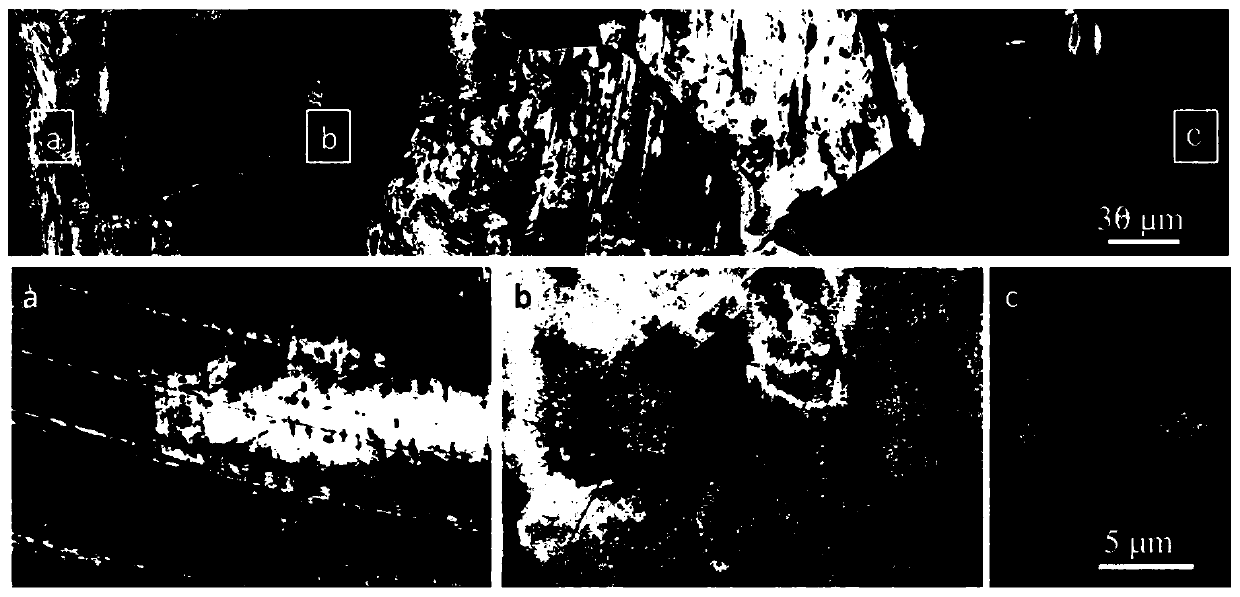

[0041] As the depth from the surface increases, the degree of deformation in the material presents a monotonically decreasing trend, forming a gradient distribution of deformation microstructure ( figure 2 ). The outermost surface is still coarse-grained ( Figure 4 ), there are high-density dislocations distributed inside the coarse grain, a large number of dislocation cells and disl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com