Chemical strengthening method of hot bending glass, hot bending strengthened glass and electronic equipment

A technology for strengthening glass and electronic equipment, which is applied in the field of materials, can solve problems such as low strengthening effect and difficult ion exchange, and achieve the effects of enhancing the strength of hot-bending glass, strong impact resistance, and enhancing glass strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

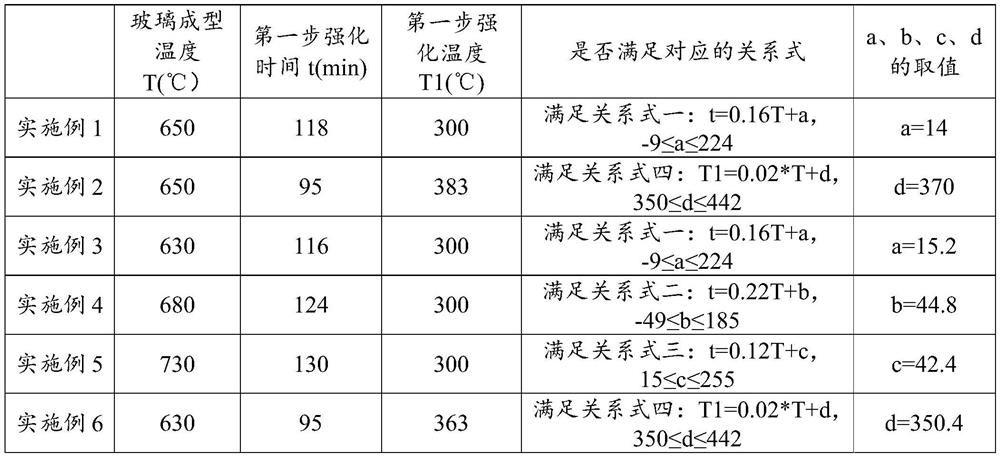

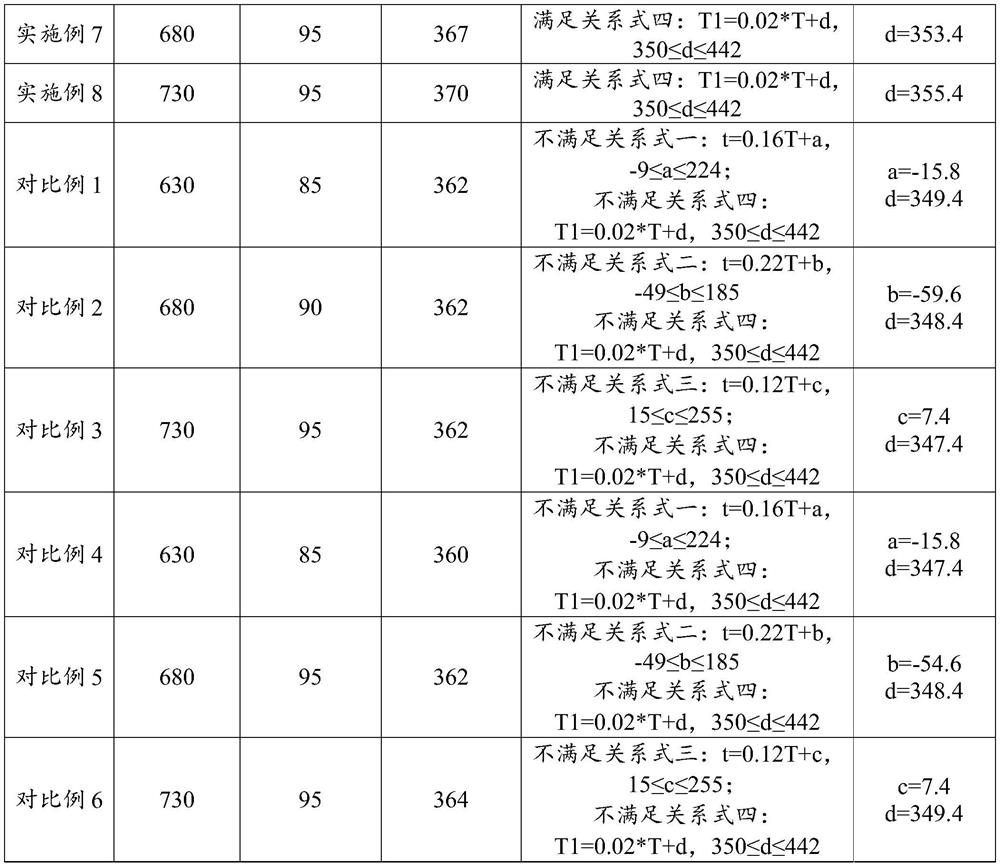

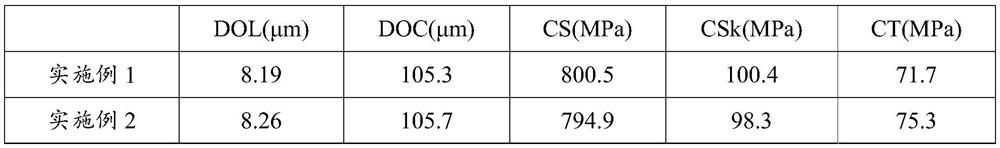

Examples

Embodiment 1

[0039] Put a flat glass preform with a thickness of 0.55mm into a hot bending machine, heat it to 650°C (that is, the temperature for hot bending is 650°C), and keep it warm for 2 minutes. The chemical composition of the flat glass preform is measured in mole percentages, including 35-70% SiO 2 , 15-30% Al 2 o 3 , 1-10% Li 2 O, 5-15% Na 2 O and 3-10% of other ingredients. After cooling to room temperature, the hot bending glass to be strengthened is obtained through CNC processing-edge sweeping-polishing-cleaning and other processes.

[0040] Put the hot bent glass into the preheating furnace for the first preheating, the time of the first preheating is 118min, and the temperature of the first preheating is 300°C.

[0041] After the preheating is completed, the hot bending glass is placed in NaNO with a mass fraction of 38%. 3 and 62% KNO 3 1. In the first molten salt at a temperature of 380° C., the first step of strengthening is carried out, wherein the time of the fi...

Embodiment 2

[0044] Put a flat glass preform with a thickness of 0.55mm into a hot bending machine, heat it to 650°C (that is, the temperature for hot bending is 650°C), and keep it warm for 2 minutes. The chemical composition of the flat glass preform is measured in mole percentages, including 35-70% SiO 2 , 15-30% Al 2 o 3 , 1-10% Li 2 O, 5-15% Na 2 O and 3-10% of other ingredients. After cooling to room temperature, the hot bending glass to be strengthened is obtained through CNC processing-edge sweeping-polishing-cleaning and other processes.

[0045] Put the hot-bending glass into the preheating furnace for the first preheating, the time for the first preheating is 95 minutes, and the temperature for the first preheating is 383°C.

[0046] After the preheating is completed, the hot bending glass is placed in NaNO with a mass fraction of 38%. 3 and 62% KNO 3 1. In the first molten salt at a temperature of 380° C., the first step of strengthening is carried out, wherein the time ...

Embodiment 3

[0049] The difference from Example 1 is that the glass forming temperature is 630° C., and the strengthening time for the first step is 116 minutes. Others are the same as in Example 1, and a strengthened glass is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com