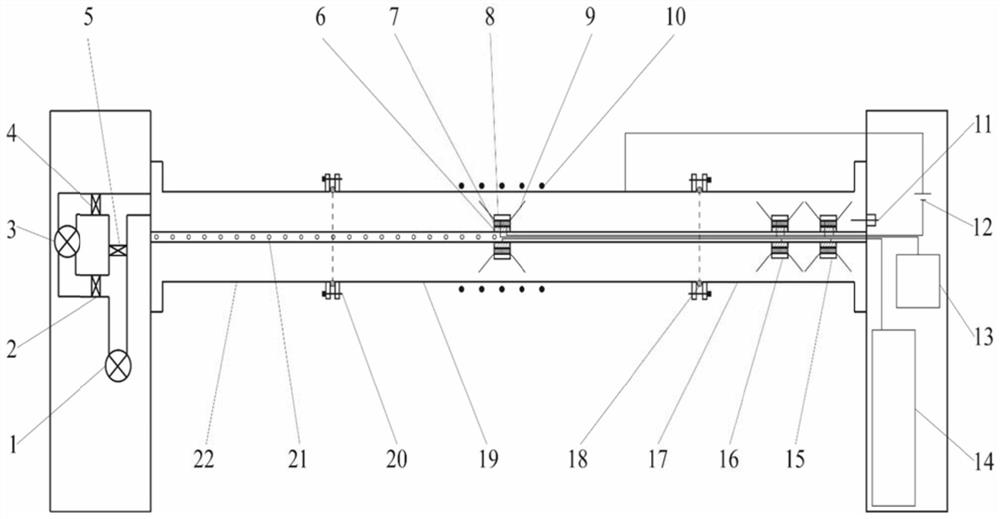

Magnetron sputtering device for coating film on inner wall of pipe with large length-diameter ratio

A magnetron sputtering device and a technology with a large aspect ratio, which is applied in sputtering coating, vacuum evaporation coating, ion implantation coating, etc., can solve the problem of uneven film, non-metallic coating, large amount of toxic solution, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The method of coating the inner wall of the large aspect ratio tube by using the above-mentioned magnetron sputtering device is as follows:

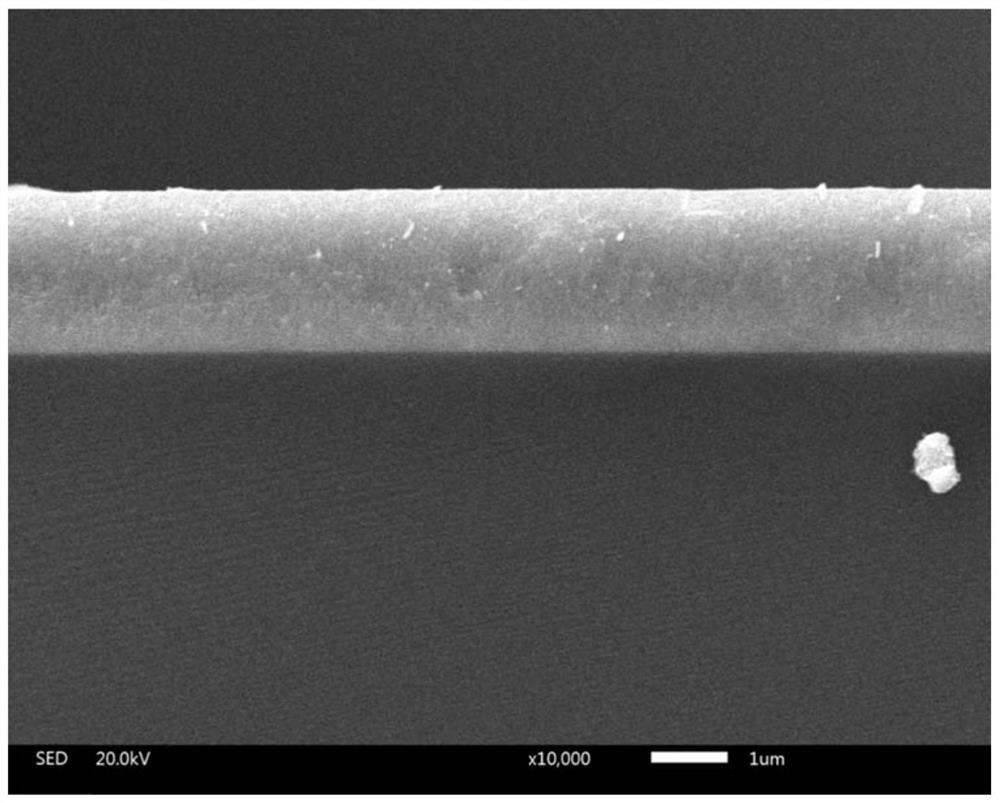

[0048] Coating the inner wall of the pipe fittings with an inner diameter of 40cm and a length of 600cm, and degreasing and decontaminating the inner wall of the pipe fittings before assembly. The target is a metal vanadium target with an outer diameter of 26cm and a purity of 99.99wt%. The axial length of the target along the hollow tube is 15cm, the thickness of the target (difference between inner and outer diameters) is 4cm, and the distance between the target surface and the inner wall of the tube is 7cm. The distance between the pores on the hollow tube is 4cm, and the diameter of the pores is 0.2cm. After the assembly is complete, pump the inside of the fitting to 1×10 -3 Pa background vacuum, turn on the medium frequency induction heating power supply, and heat the tube to 150°C. Argon gas (purity 99.999%) was introduced...

Embodiment 2

[0051] The method of coating the inner wall of a large aspect ratio tube by using a magnetron sputtering device is as follows:

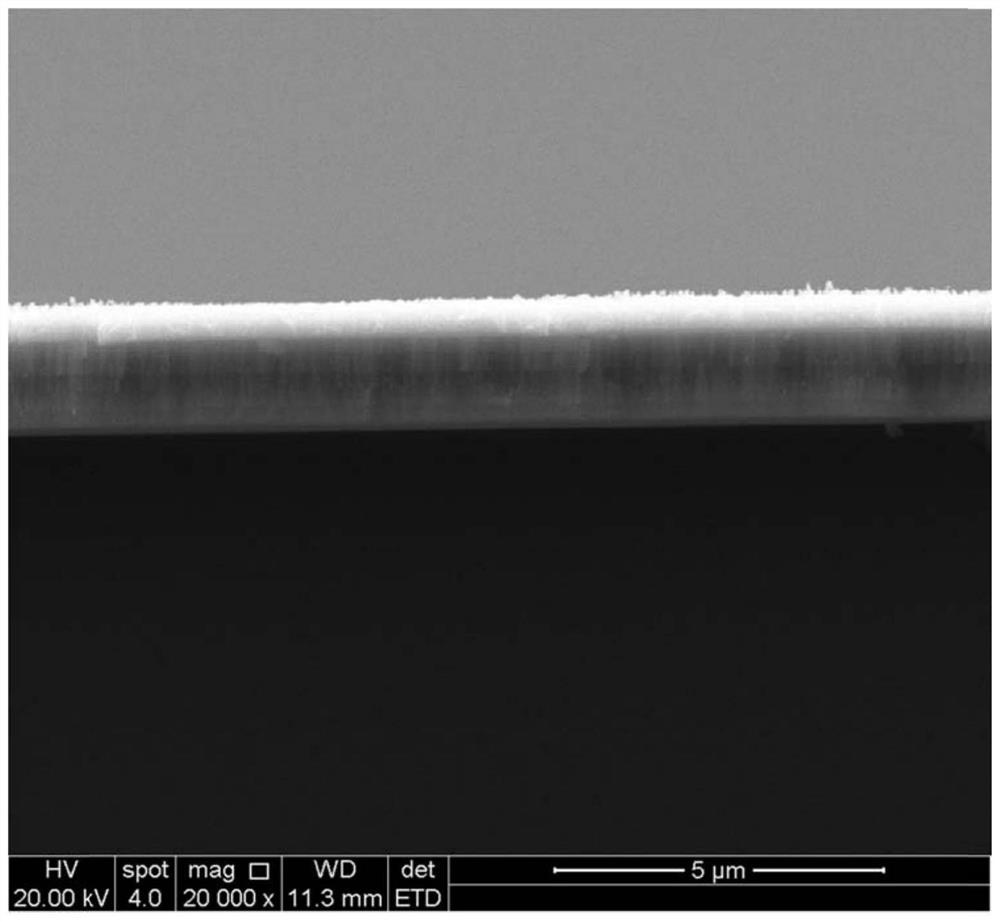

[0052] Multi-layer composite coating is applied to the inner wall of the pipe fittings with an inner diameter of 60cm and a length of 800cm. Before assembly, the inner wall of the pipe fittings is degreased and decontaminated. The target material adopts metal Ti target, TiCr target and TiAl target with an outer diameter of 40cm and a purity of 99.99wt%. The inner walls are 10cm apart. The distance between the pores on the hollow tube is 4cm, and the diameter of the pores is 0.2cm. After assembly, pump down the deposition chamber to 1 x 10 -3 Pa background vacuum degree, turn on the medium frequency induction heating power supply, and heat the pipe fittings to 200°C. Introduce argon gas (purity 99.999%), set the flow rate of argon gas to 100 sccm, and adjust the deposition pressure to 0.4Pa, move the target to the adapter of the power supply end fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com