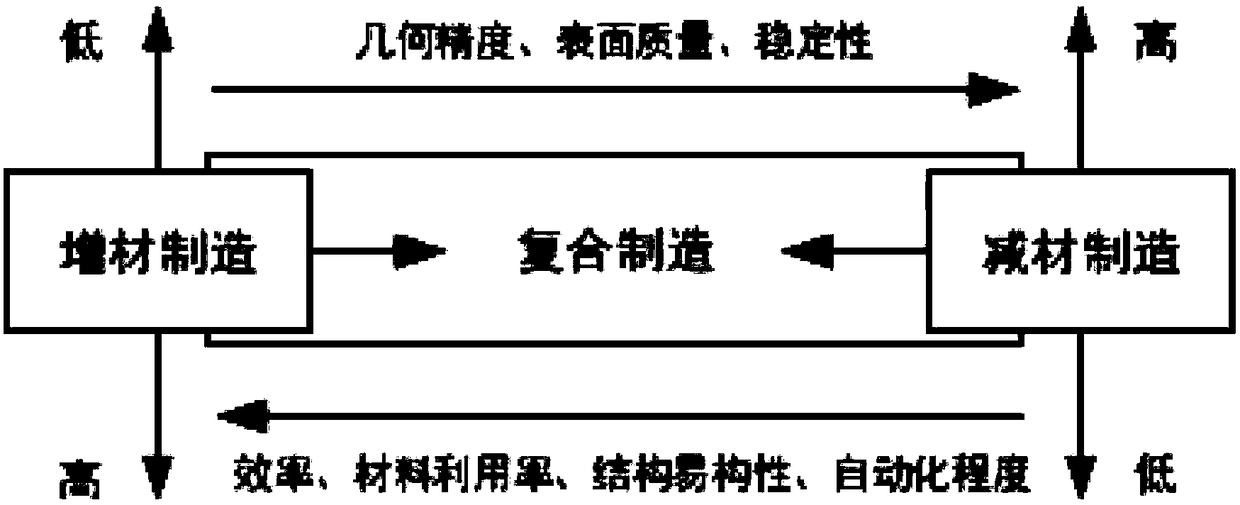

Composite additive, accumulative and subtractive processing device with multi-robot cooperation, and process method

A multi-robot, composite processing technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve problems such as low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

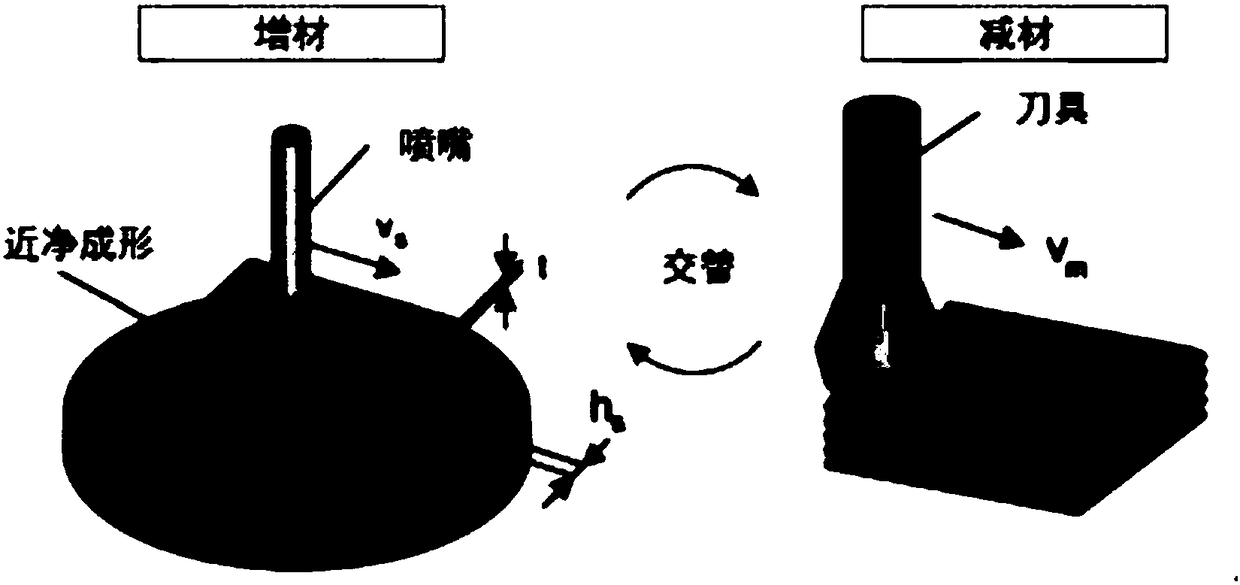

Method used

Image

Examples

Embodiment Construction

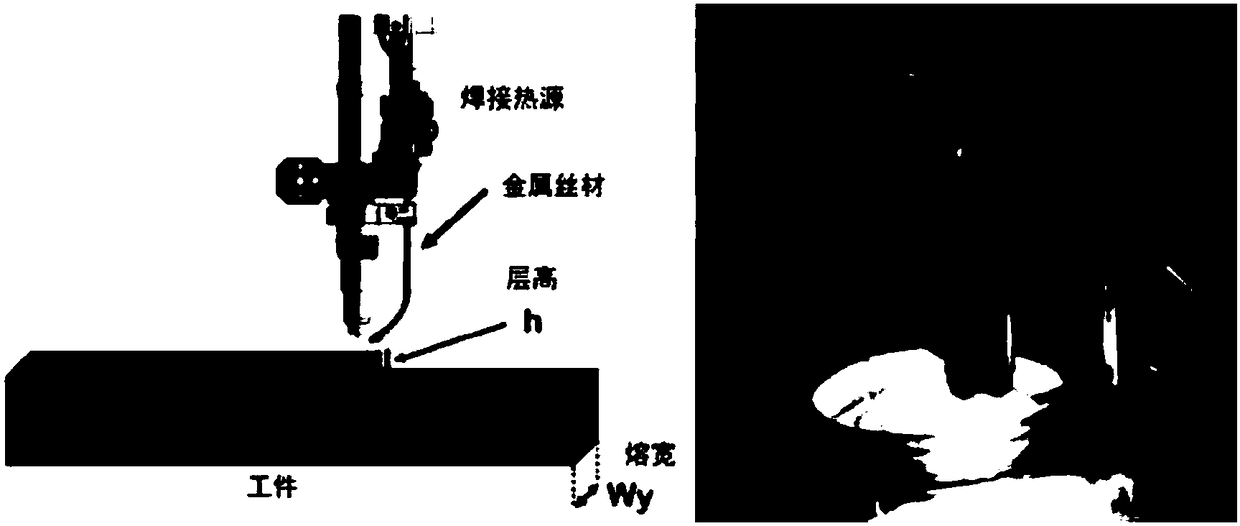

[0073] In this example, Figure 7 Flowchart for the composite machining process of adding and subtracting materials for robots. The processed parts can be scanned or modeled to form the required three-dimensional data. The welding wire additive manufacturing process is a layer-by-layer cladding principle. By adjusting the welding process parameters, the cross-sectional shape of components with different heights and spreading thicknesses can be formed. The welding methods include MAG (melting active gas arc welding), MIG (melting arc inert gas arc welding), and TIG (tungsten inert gas arc welding). ), PA (plasma welding), etc. The arc generated by the welding machine is the heat source, and the STL file required for the sheet is generated under program control through the addition of wire (welding wire), and the manufacturing process of metal parts is gradually formed from line-surface-body according to the three-dimensional digital model.

[0074]Complete the integrated manu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com