Surface microstructure based high-accuracy length detection method

A detection method and high-precision technology, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of high detection accuracy, large range, and inability to obtain measurement results on the surface, and achieve high-precision displacement detection. The effect of machining accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

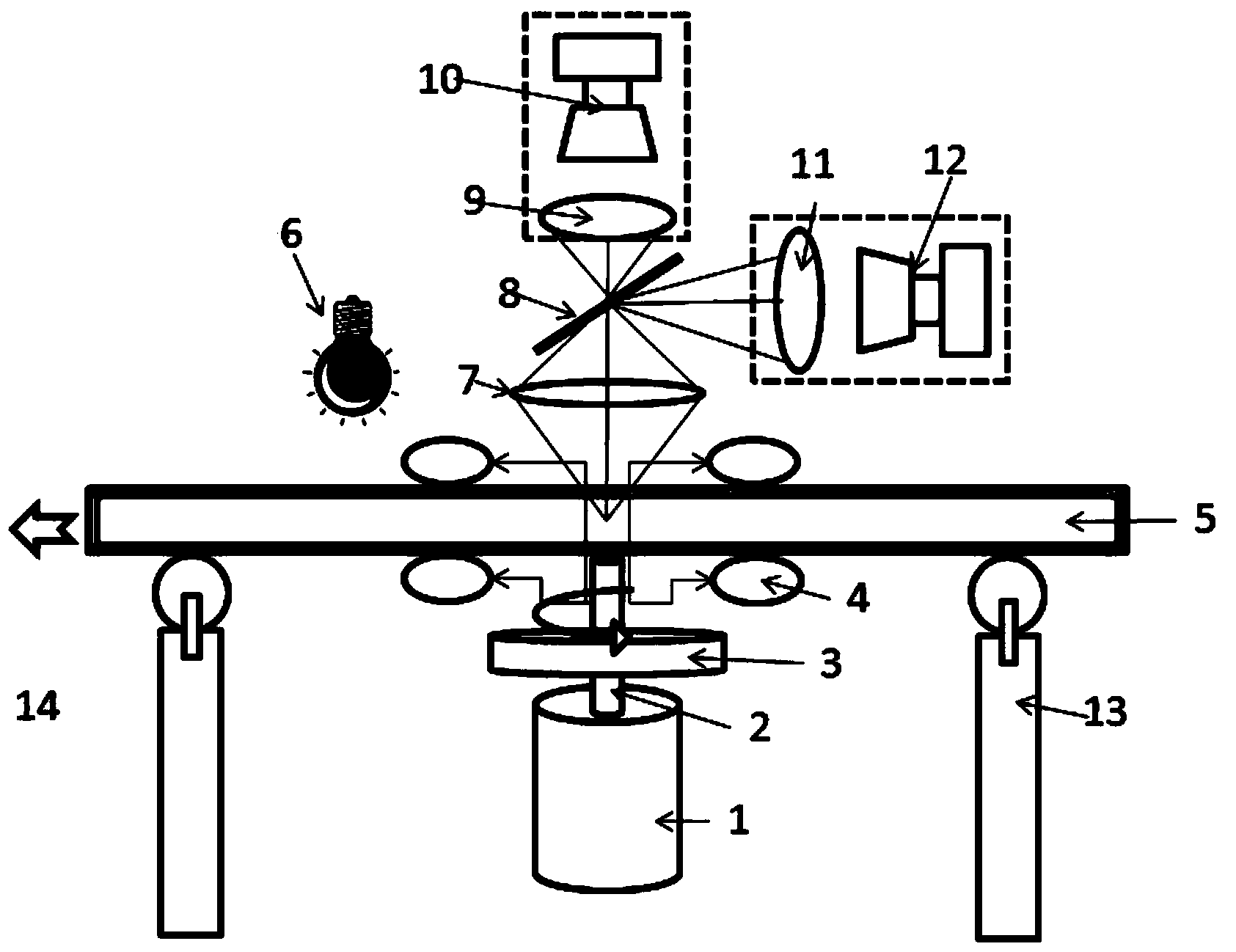

[0015] A high-precision length detection method based on surface microstructure, the specific implementation steps are as follows: figure 1 as shown,

[0016] Step 1, adjust the measuring equipment to be in a horizontal state, turn on the illumination light source 6 above the equipment to be tested, and start the first image acquisition system 10 and the second image acquisition system 12 .

[0017] Step 2, place the object 5 to be measured on the support structure 13, fix and level the object 5 to be measured with four anti-shake driving devices 4 clamped on the sides of the object to be measured. The object 5 to be measured may be a device that requires precise length measurement, such as a grating ruler.

[0018] Step 3, through the images obtained by the high-resolution first image acquisition system 10 and the second image acquisition system 12 located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com