Novel spiral chip remover driving device

A technology of transmission device and chip conveyor, which is applied in the direction of transmission device, maintenance and safety accessories, belt/chain/gear, etc. It can solve the problems of unstable transmission, failure of motor water inlet seal, waste of power source, etc., and achieve flexible design , small footprint, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

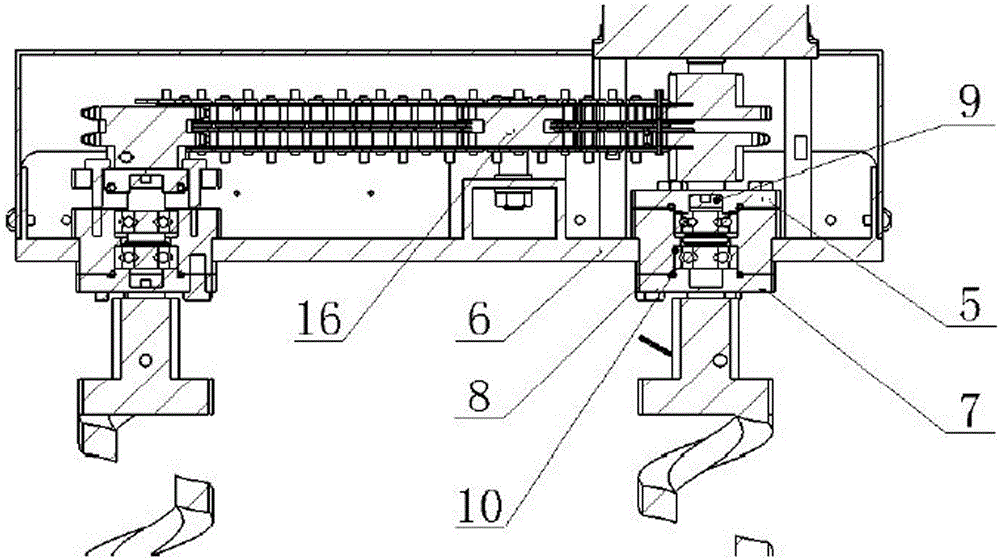

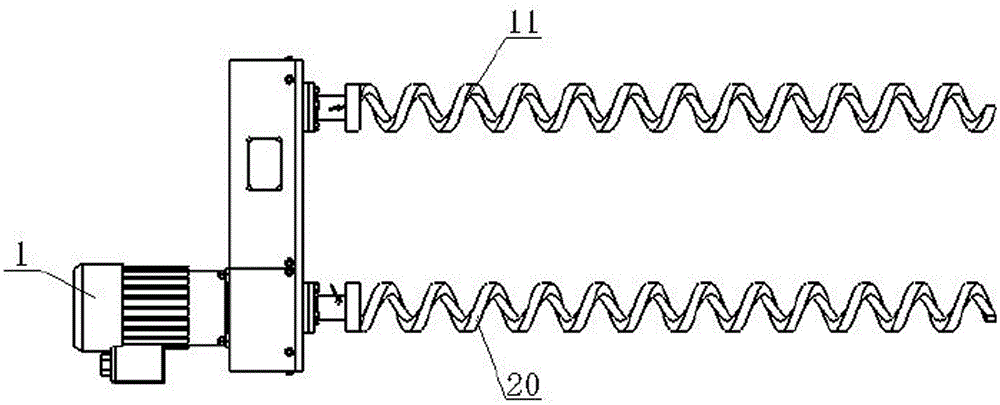

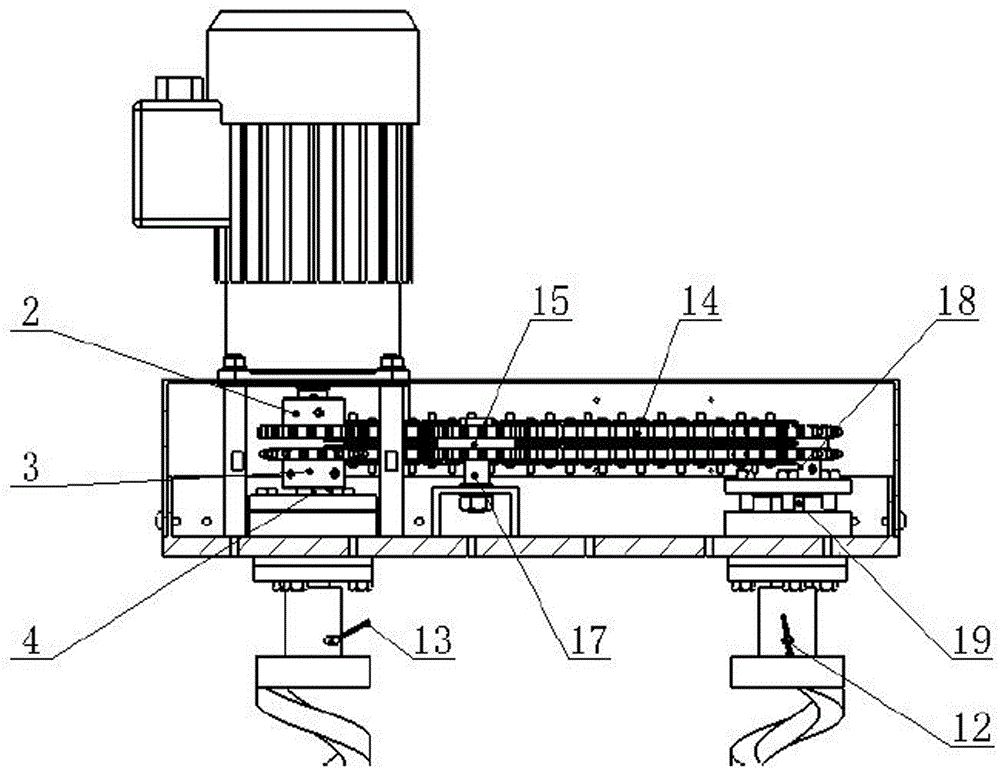

[0020] Such as figure 1 , 2 As shown in , 3, a new type of spiral chip conveyor transmission device according to the present invention includes a drive motor 1, a first driving sprocket 2, a second driving sprocket 3, a transmission shaft 4, a bearing support 6, a first screw Rod 11, pin shaft 12, double row roller chain 14, tensioning wheel 15, tensioning bearing 16, tensioning shaft 17, double tooth driven sprocket 18, driven shaft 19, second screw rod 20, drive The output shaft of the motor is connected with the first drive sprocket through a keyway, the second drive sprocket is arranged side by side with the first drive sprocket, the double-row roller chain is installed on the first and second drive sprocket, the first The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com