Sealing device of recoil roller chip removal device

A technology of sealing device and recoil drum, which is applied in the direction of engine sealing, maintenance and safety accessories, mechanical equipment, etc., can solve the problems such as the specific method of the sealing structure is not introduced in detail, and the sealing effect cannot be guaranteed, and achieves flexible design and size. The effect of small restriction and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples.

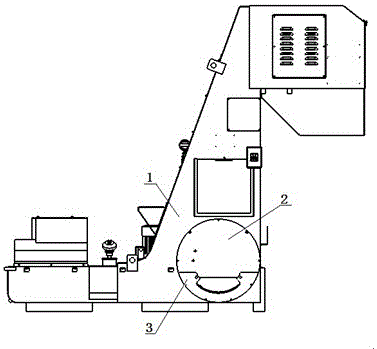

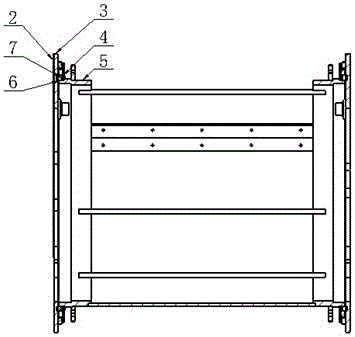

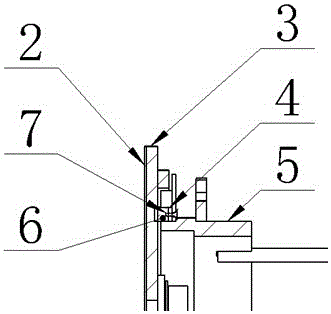

[0029] Such as Figure 1-3 As shown, the sealing device of the recoil drum chip conveyor includes: chip conveyor main body 1, cover plate 2, drum end cover 3, rubber pad 4, drum 5, packing 6, self-tapping screw 7, wherein the chip conveyor main body The deceleration motor on 1 drives the chain plate to run through the meshing transmission of the chain and the sprocket, and the gear teeth on the chain plate and the drum 5 mesh to drive the drum to rotate. The drum end cover 3 is fixedly connected to the chip conveyor main body 1, and the cover plate 2 is fixed on the drum end cover 3. The preferred connection method is bolt connection, that is, the drum cover plate 3 is connected to the chip conveyor main body 1 by bolts. The cover plate 2 is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com