Scrap tire rubber bould crusher

A technology of coarse shredders and waste tires, which is applied in the direction of mechanical material recovery, recycling technology, grain processing, etc. It can solve the problems of waste of resources, crushing, and large one-time investment, so as to enhance the working capacity of the machine, realize automatic control, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

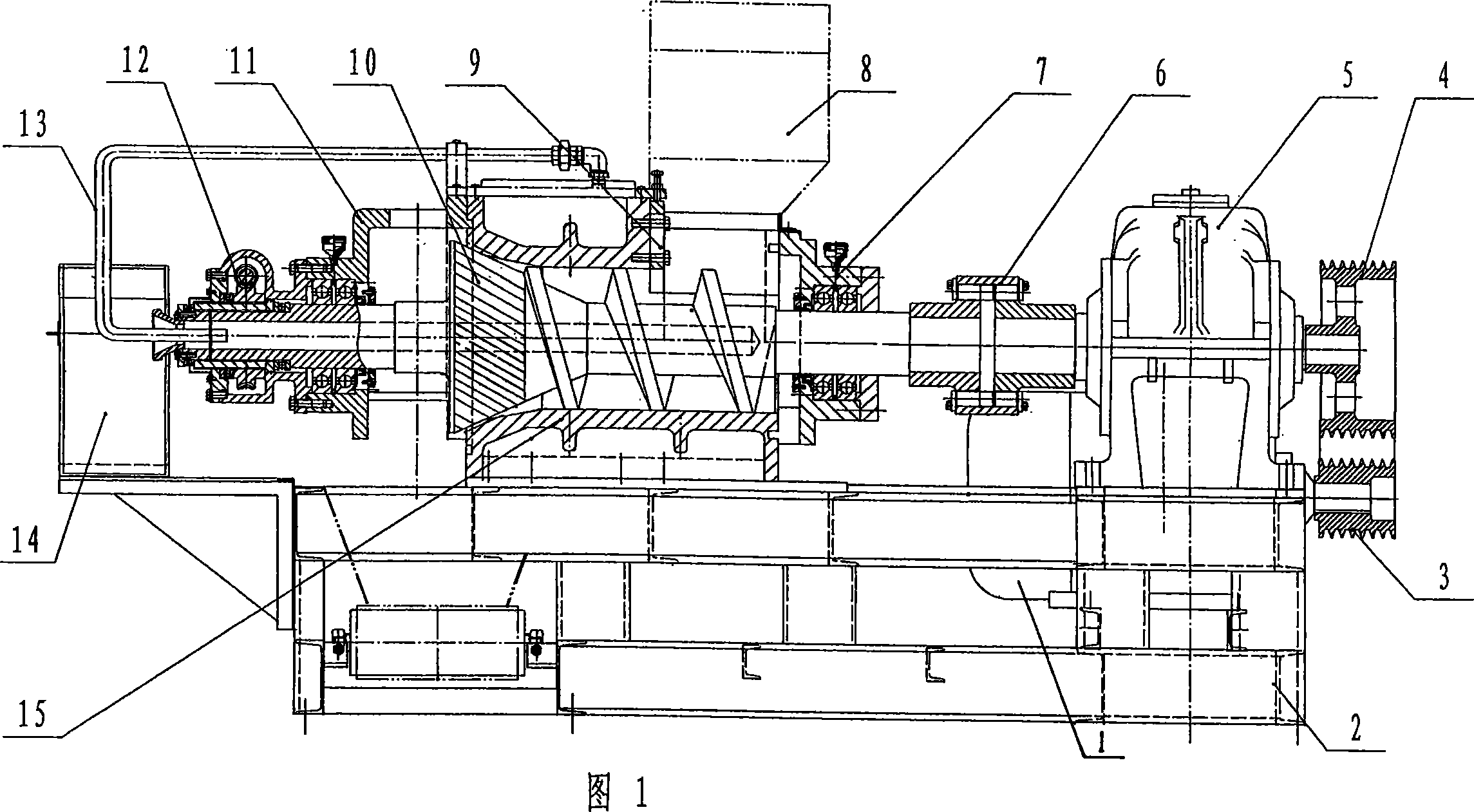

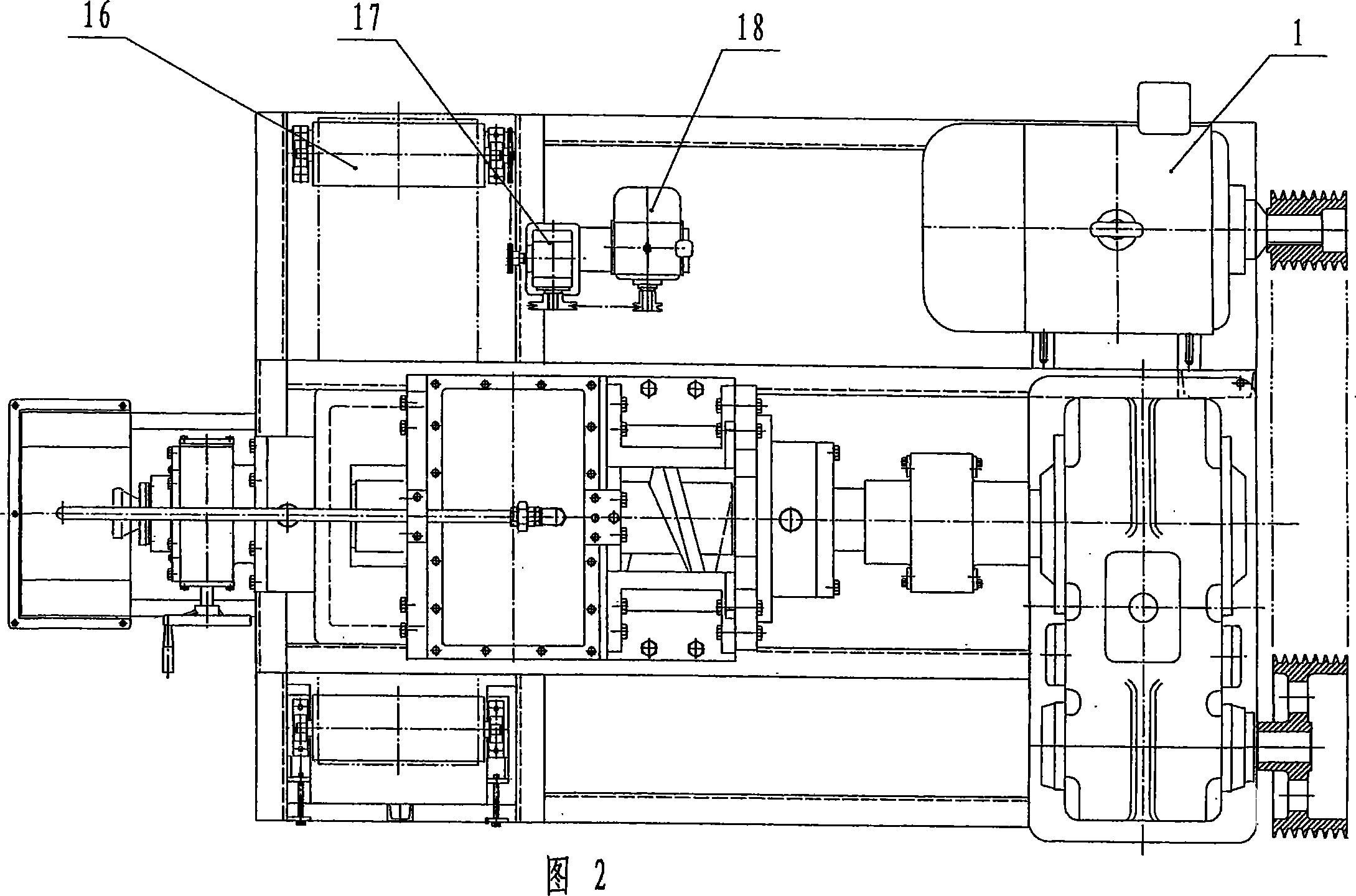

[0009] As shown in Figure 1 and Figure 2, the waste tire rubber coarse shredder is mainly composed of a machine base, a motor, a reducer and a crushing mechanism. 5, the output shaft of the reducer 5 is connected to the working rotor 10 of the crushing mechanism through the coupling 6, and drives the working rotor 10 to run. The spiral feeding blade and the crushing gear are composed of two parts, and the working rotor 10 cooperates with the inner wall of the crushing chamber 15 to form a spiral pair. The feeding port of the pulverizing chamber 15 is provided with a fixed blade 9, the edge of which is arc-shaped, cooperates with the screw feeding blade of the working rotor 10 to form a cutting mechanism, and cuts the waste tire rubber sheet.

[0010] The discharge end of the crushing chamber 15 is provided with a cavity with a discharge port, and a cooling water tank is provided along the periphery of the crushing chamber 15, and the circulating cooling water is input from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com