High-strength high-ductility biodegradable Zn-Mn-Mg series zinc alloy and preparation method thereof

A zn-mn-mg, biodegradable technology, applied in the field of composition design and preparation and processing of medical materials, can solve the problem of not providing data on the yield strength of zinc alloys, and achieve the effects of low cost, brittleness inhibition, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

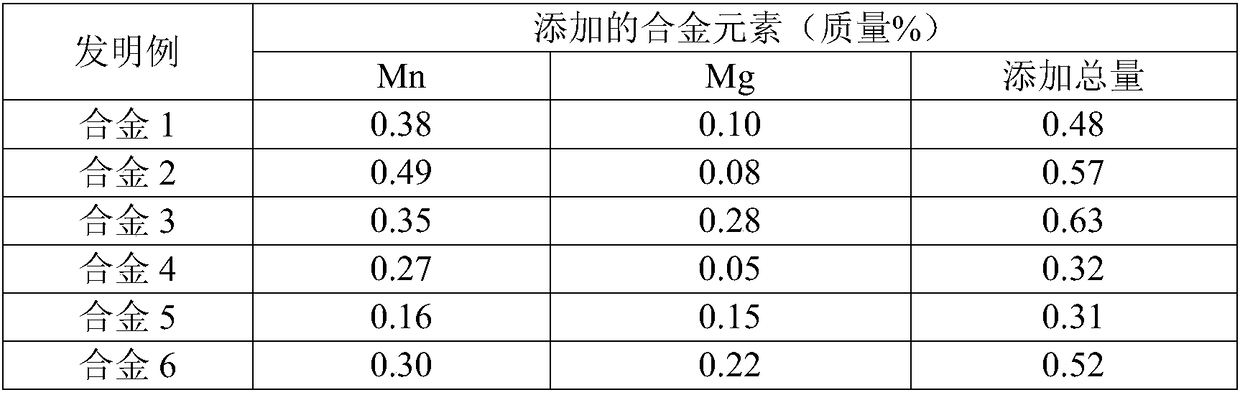

[0063] Composition, Preparation, Microstructure and Properties of High Strength and High Plasticity Zn-Mn-Mg Ternary Zinc Alloy.

[0064] The chemical composition of the zinc alloy is shown in Table 1-1, and the balance is Zn. The preparation process of the alloy is: vacuum directional solidification→extrusion. Using high-purity Zn blocks and high-purity Mn and Mg powders as raw materials, the vacuum degree of vacuum directional solidification is 2×10 -4 Pa, the heating temperature is 700°C, the standing time is 10 minutes, the cooling medium is liquid metal, and the pull-down speed is 50 μm / s.

[0065] The extrusion is carried out at 230° C., the extrusion speed is 2 mm / min, and the extrusion ratio is 16.

[0066] Samples were cut from the extruded rods of the zinc alloy to be tested for electrochemical corrosion, immersion corrosion, cytotoxicity and tensile mechanical properties at room temperature.

[0067] The preparation method of the electrochemical corrosion sample ...

Embodiment 2

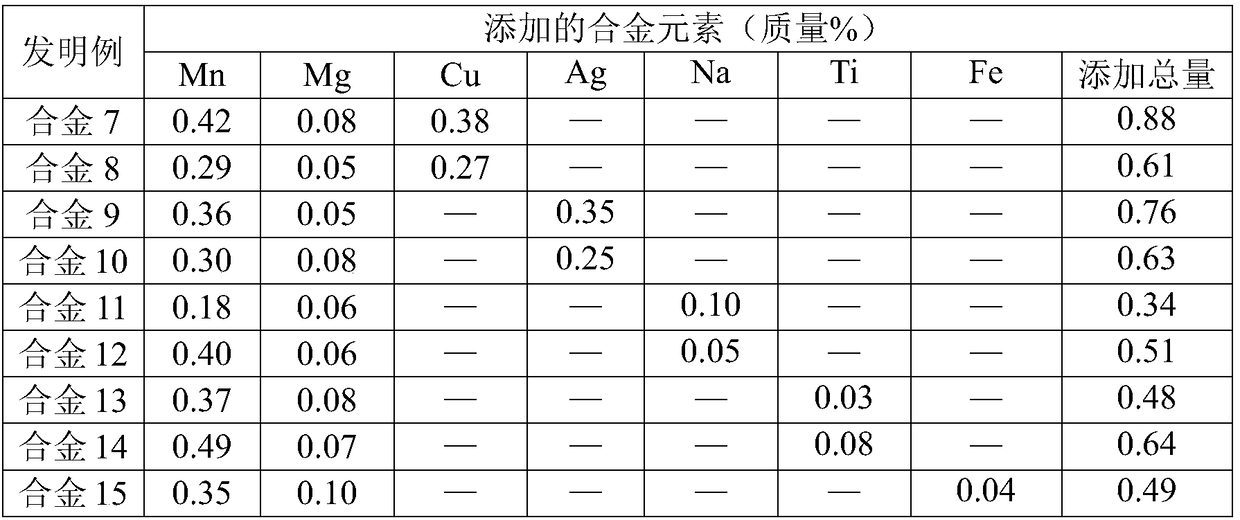

[0079] Composition, Preparation, Microstructure and Properties of High Strength and High Plasticity Zn-Mn-Mg Quaternary Alloys.

[0080] The chemical composition of the zinc alloy is shown in Table 2-1, and the balance is Zn. The preparation process of the zinc alloy is: vacuum directional solidification→extrusion→two-stage heat treatment→cold rolling→drawing. Using high-purity Zn block, high-purity Mn, Mg, Cu, Ag, Fe, Ti powder and high-purity Na block as raw materials, the vacuum directional solidification and extrusion process follows the method provided in Example 1.

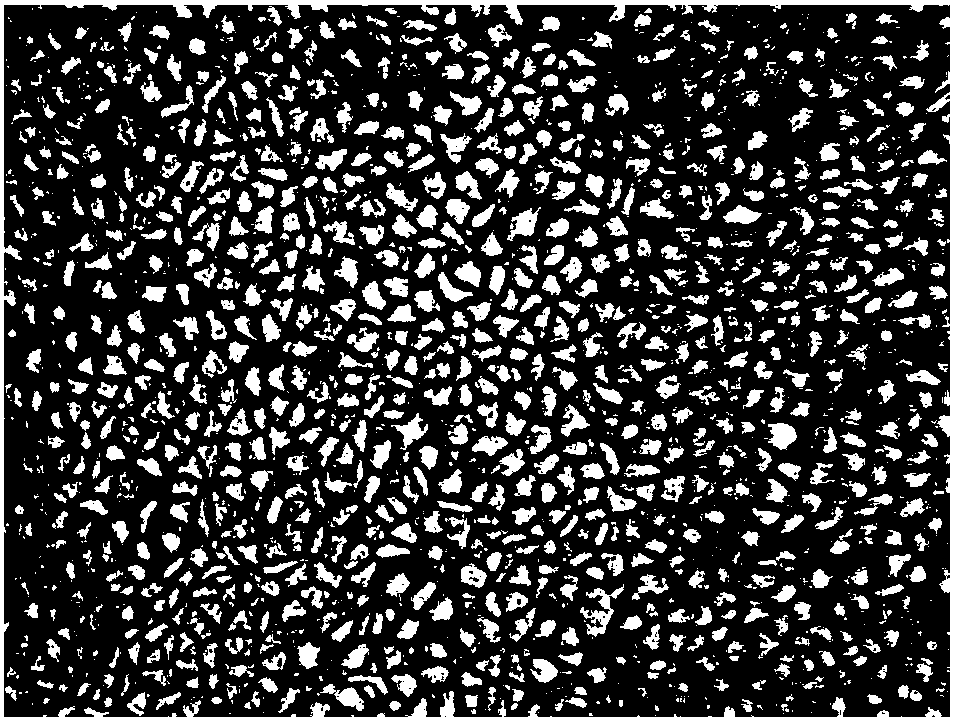

[0081] The first-stage heat treatment regime of the two-stage heat treatment is 380° C. for 3 hours, and the second-stage heat treatment is 120° C. for 20 minutes. Using transmission electron microscope and scanning electron microscope to observe the alloy structure after two-stage heat treatment, micron-sized MnZn with a size of 1-10 μm was observed 13 and Mg 2 Zn 11 Particles and nanoscale MnZn with a ...

Embodiment 3

[0094] Composition, preparation, microstructure and properties of high-strength and high-plasticity Zn-Mn-Mg series quinary alloys.

[0095] The chemical composition of the zinc alloy is shown in Table 3-1, and the balance is Zn. It uses high-purity Zn block and high-purity Mn, Mg, Ca, Sr, Ti, Cu, Ag powder as raw materials. The preparation process of the zinc alloy is: vacuum directional solidification→first extrusion→two-stage heat treatment→second extrusion→annealing (optional).

[0096] The vacuum degree of the vacuum directional solidification is 8×10 -3 Pa, the heating temperature is 750°C, the melt resting time is 8 minutes, the cooling medium is circulating cooling water whose temperature is maintained at 15±1°C, and the pull-down speed is 100μm / s.

[0097] The first extrusion is carried out at 260° C., the extrusion speed is 3 mm / min, and the extrusion ratio is 25.

[0098] The first-stage heat treatment system of the two-stage heat treatment is 380°C for 10 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com