Welding method for conducting build up welding through stellite alloy

A welding method and special alloy technology, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problem of easy crack or brittle crack, avoid crack or brittle crack, long service life, reduce stress and strain rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

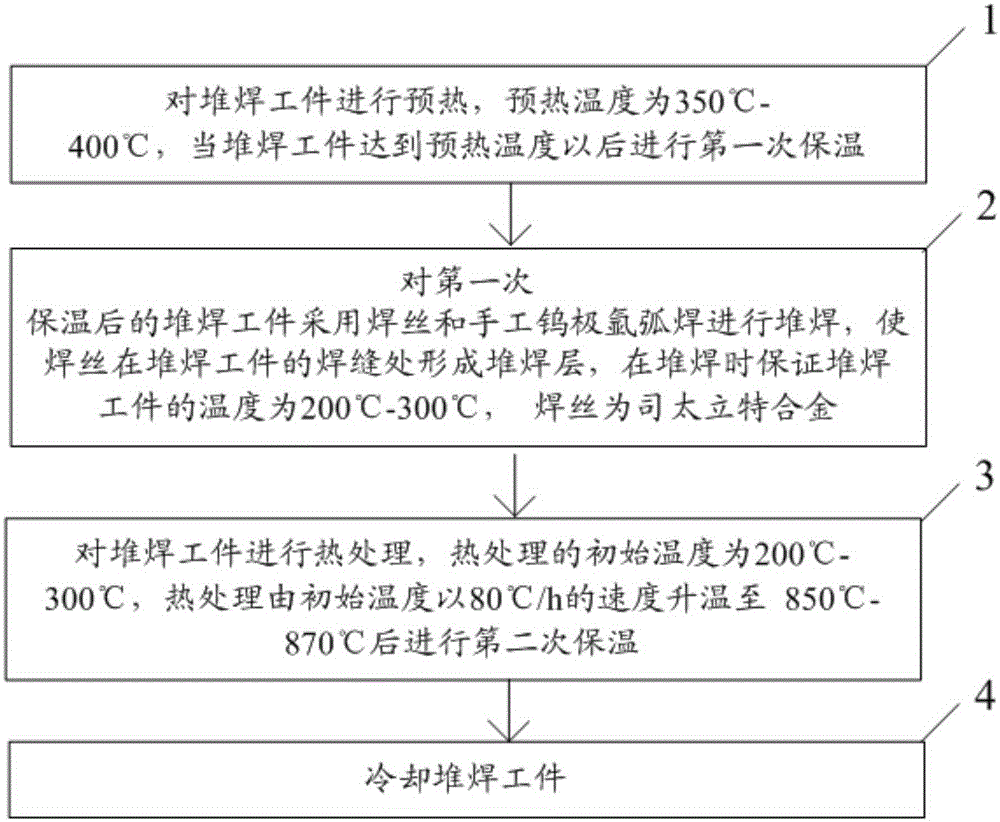

[0025] The embodiment of the present invention provides a welding method using stellite alloy for surfacing welding, which is suitable for surfacing welding of stellite hard alloy layer of gas turbine front casing, such as figure 1 Shown method flowchart, this method comprises:

[0026] Step 1: Preheat the surfacing welding workpiece. The preheating temperature is 350°C-400°C. When the surfacing welding workpiece reaches the preheating temperature, perform the first heat preservation.

[0027] Step 2: Use welding wire and manual argon tungsten arc welding for the surfacing workpiece after heat preservation, so that the welding wire forms a surfacing layer on the surfacing workpiece, and ensure that the temperature of the surfacing workpiece is 200 during welding. ℃-300℃, the welding wire is stellite alloy, and the composition of the welding wire includes: carbon, chromium, tungsten, silicon, manganese, iron, nickel and cobalt, the weight part of carbon is 0.9-1.4 parts, and th...

Embodiment 1

[0041] Specifically, the thickness of the surfacing welding workpiece is 25 mm, and the thickness of the surfacing welding layer is 3 mm.

[0042] Step 1: Preheat the surfacing workpiece. The preheating temperature is 350°C. When the surfacing workpiece reaches the preheating temperature, perform the first heat preservation. The first heat preservation time is 0.5h.

[0043] Step 2: Use welding wire and manual argon tungsten arc welding for the surfacing workpiece after heat preservation, so that the welding wire forms a surfacing layer on the surfacing workpiece, and ensure that the temperature of the surfacing workpiece is 200 during welding. ℃, the welding wire is stellite alloy, and the composition of the welding wire includes: carbon, chromium, tungsten, silicon, manganese, iron, nickel and cobalt, the weight part of carbon is 0.9 parts, the weight part of chromium is 26.0 parts, and the weight part of tungsten Parts by weight are 3.0 parts, parts by weight of silicon ≤ 2...

Embodiment 2

[0052] Embodiment two adopts the processing method identical with embodiment one, and method difference is as follows:

[0053] Specifically, the thickness of the surfacing welding workpiece is 45 mm, and the thickness of the surfacing welding layer is 6 mm.

[0054] Step 1: Preheat the surfacing workpiece. The preheating temperature is 400°C. When the surfacing workpiece reaches the preheating temperature, perform the first heat preservation. The time of the first heat preservation is 1.5h.

[0055] Step 2: Use welding wire and manual tungsten argon arc welding for the surfacing workpiece after heat preservation, so that the welding wire forms a surfacing layer on the surfacing workpiece, and ensure that the temperature of the surfacing workpiece is 300 during welding. ℃, the welding wire is stellite alloy, and the composition of the welding wire includes: carbon, chromium, tungsten, silicon, manganese, iron, nickel and cobalt, the weight part of carbon is 1.4 parts, the weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com