High-toughness ductile blade steel and metallurgical manufacturing method thereof

A manufacturing method and high-strength-toughness technology, applied in the field of metallurgical manufacturing and blade steel, can solve the problems of increasing manufacturing cost, increasing energy consumption, low product grade, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The mass percentage of the chemical composition of the steel in this embodiment is: C: 0.61; Mn: 0.48; Cr: 7.90; Si: 0.88; Mo: 1.80; W: 1.35; V: 0.26; Cu≤0.30; Ni: 0.15; P: 0.013; S: 0.012; the rest is Fe and unavoidable impurities.

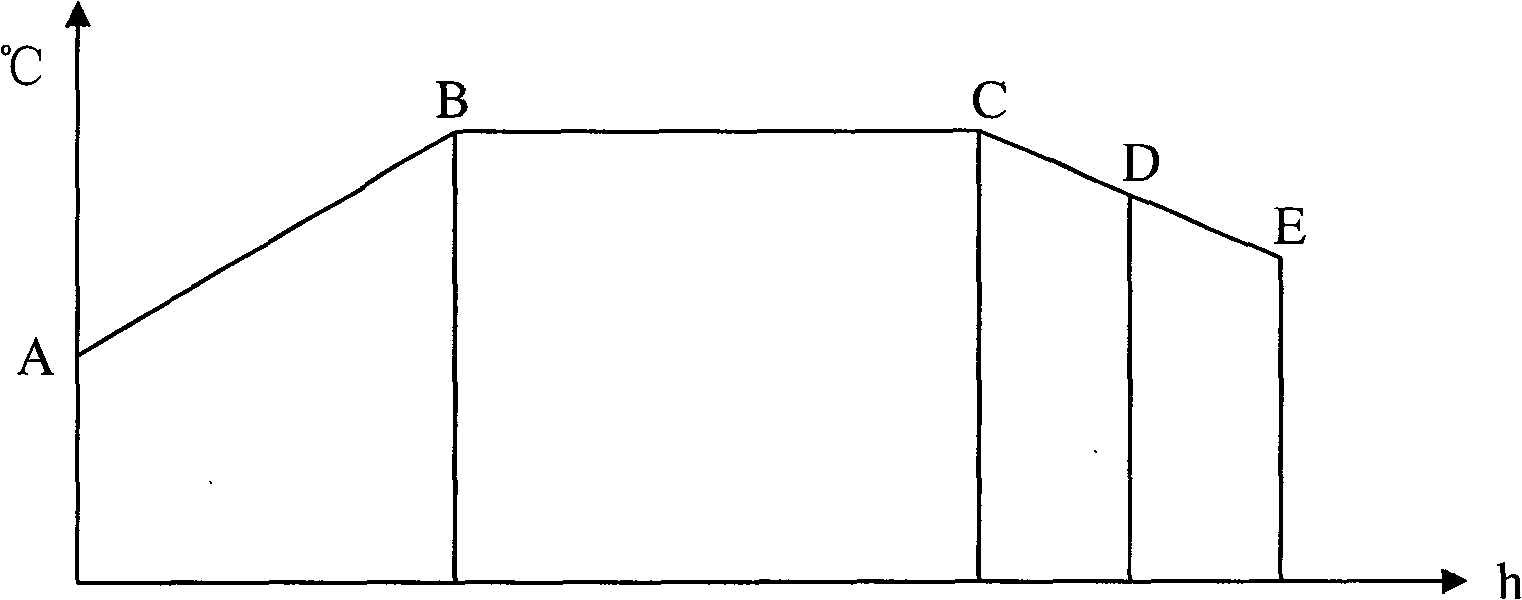

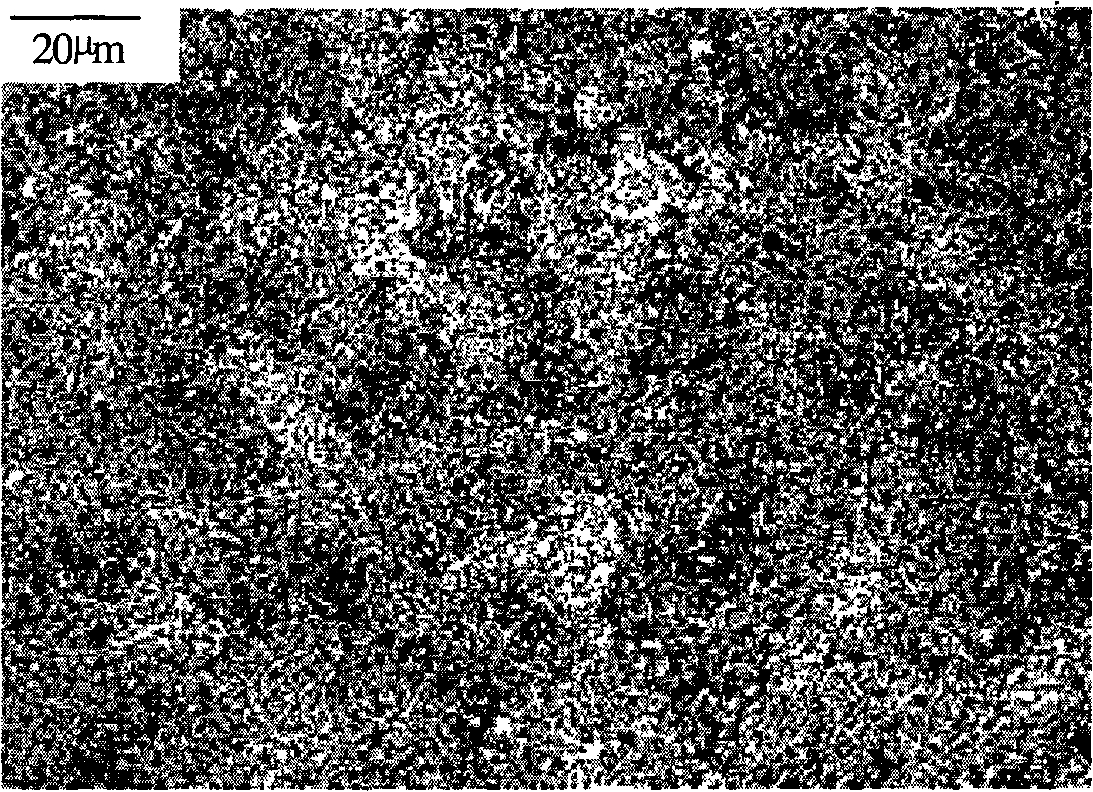

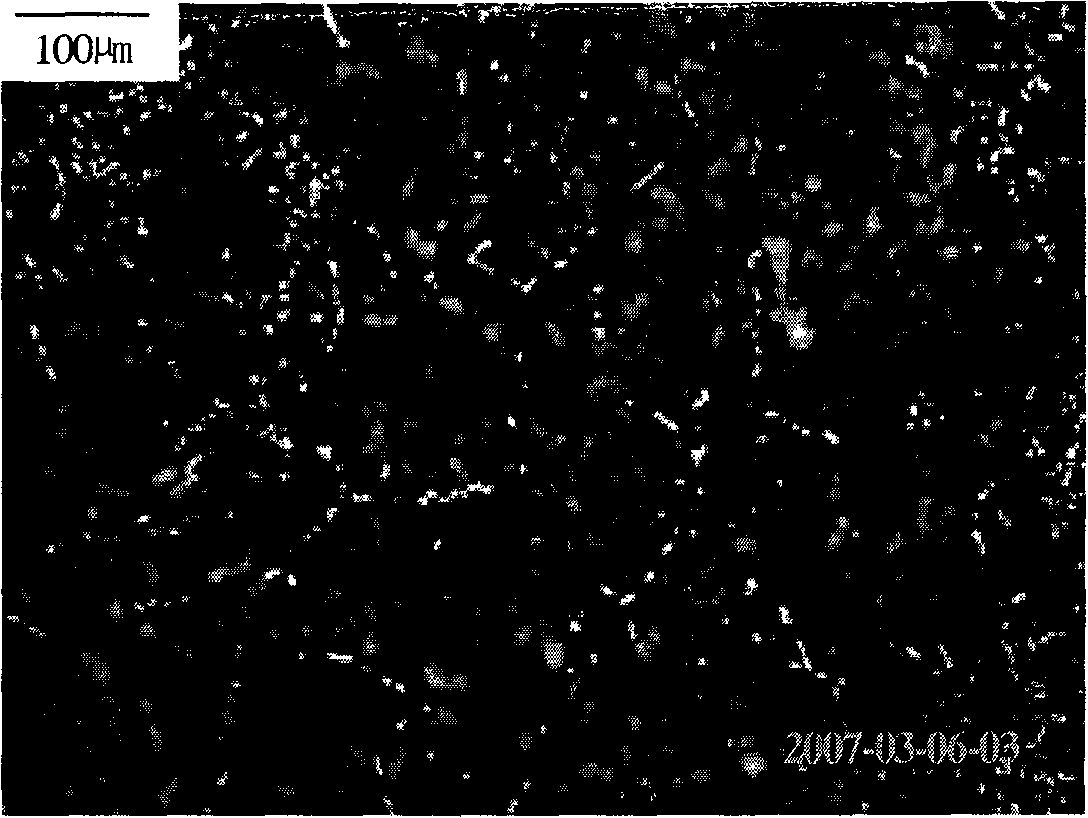

[0050] After refining in the electric furnace and outside the furnace, it is poured into a 1200kg steel ingot. The steel ingot is heated in the forging heating furnace of the radial forging machine. The temperature of the ingot is 650℃, and the heating rate of the steel ingot is 80℃ / h in the forging heating furnace of the radial forging machine. After heating to 1143℃, keep for 4.0 hours, see the heating process curve figure 1 Shown. figure 1 The heating rate and soaking time of Sinosteel ingots are reasonably controlled. The control of the forging temperature and the stop forging temperature can make the plastic deformation of the steel in the forging process proceed smoothly, and it is not suitable for cracking. The grains after deformatio...

Embodiment 2

[0053] The mass percentage of the chemical composition of the steel in this embodiment is: C: 0.65; Mn: 0.30; Cr: 7.70; Si: 0.78; Mo: 1.67; W: 1.22; V: 0.40; Cu: 0.21; Ni: 0.11; P: 0.010; S: 0.015; the rest is Fe and unavoidable impurities.

[0054] The entering temperature of the steel ingot is 680℃, and the steel ingot is heated to 1 130℃ at a heating rate of 60℃ / h in the forging heating furnace of the radial forging machine, and then kept for 3.0 hours. The forging temperature is 1025℃, and the forging temperature is 900℃. The rest is the same as in Example 1.

Embodiment 3

[0056] The mass percentage of the chemical composition of the steel in this embodiment is: C: 0.57; Mn: 0.33; Cr: 8.20; Si: 0.75; Mo: 1.78; W: 1.45; V: 0.28; Cu: 0.30; Ni: 0.25; P: 0.019; S: 0.009; the rest is Fe and unavoidable impurities.

[0057] The entering temperature of the steel ingot is 800℃, and the steel ingot is heated to 11-60℃ at a temperature rising rate of 80℃ / h in the forging heating furnace of the radial forging machine, and then kept for 5.0 hours. The open forging temperature is 1000°C, and the stop forging temperature is 950°C. The rest is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com