Continuous casting slab automatic marking device

An automatic and labeling technology, which is applied in the field of continuous casting equipment, can solve problems such as inability to determine casting strands in time and high labor intensity of workers, and achieve the effects of reducing labor intensity of workers, narrowing the scope of picking waste, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

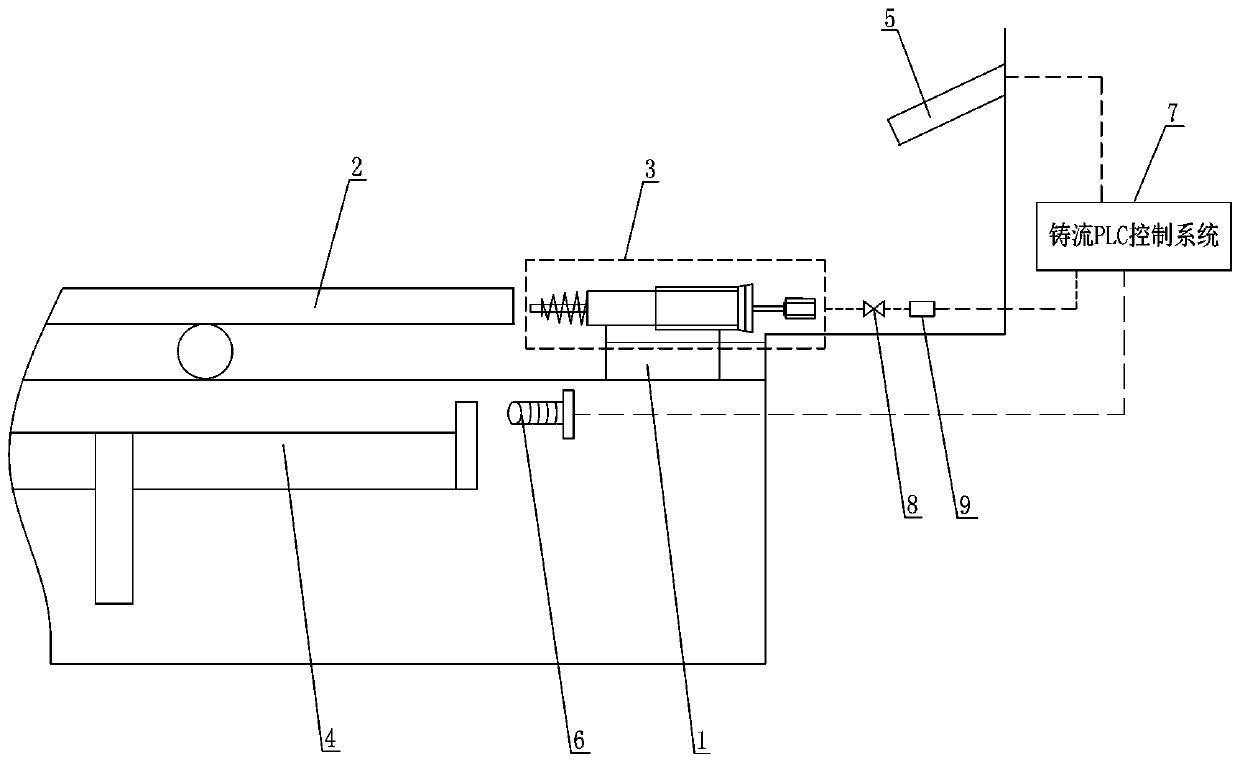

[0013] Such as figure 1 As shown, the continuous casting slab automatic labeling device includes a pneumatic actuator 3 installed on the end baffle plate 1 of the conveying roller table corresponding to the strand and capable of marking the corresponding strand number on the slab 2, The hot metal detector 5 installed above the pneumatic actuator 3 and capable of detecting whether the slab 2 has reached the top of the turner 4, and the proximity switch of the turner installed below the pneumatic actuator 3 and capable of detecting whether the turner 4 has been turned in place 6, and the casting PLC control system 7 electrically connected with the pneumatic actuator 3, the hot metal detector 5 and the steel turning machine proximity switch 6 at the same time; when the hot metal detector 5 detects that the casting slab 2 reaches the top of the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com