Explosive welding machining method for stainless steel magnesium alloy composite plates

A technology for explosive welding and magnesium alloy plates, which is applied to metal processing equipment, welding equipment, welding/welding/cutting items, etc., can solve problems such as brittle cracking, and achieve the effect of reducing area area, efficient connection and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0041] (1) Select AZ31B magnesium alloy plate and 316L stainless steel plate as the base material for explosive welding; and anneal and toughen the AZ31B magnesium alloy plate, the annealing temperature is 300°C, and the holding time is 120min;

[0042]AZ31B magnesium alloy plate: 950mmX550mmX8mm;

[0043] 316L stainless steel plate: 1000mmX600mmX2mm;

[0044] (2) Use mechanical grinding to remove the oxide layer and impurities on the interface between the AZ31B magnesium alloy plate and the 316L stainless steel plate to be bonded: that is, use an angle grinder equipped with a grinding wheel and a wire brush to initially grind the interface between the stainless steel and the magnesium alloy to be bonded, Then use 600-mesh sandpaper to polish, so that the roughness Ra of the surface to be bonded does not exceed 2 μm, and then wipe the surface to be bonded with a dry cloth.

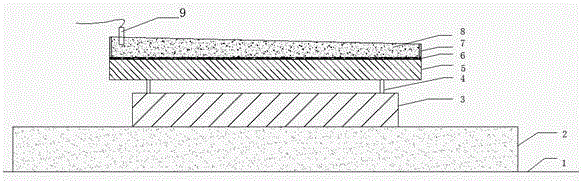

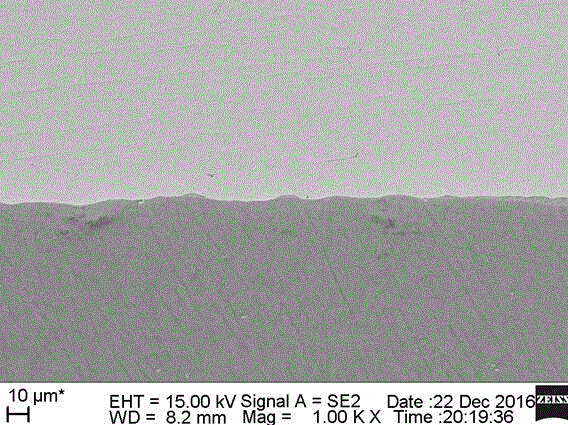

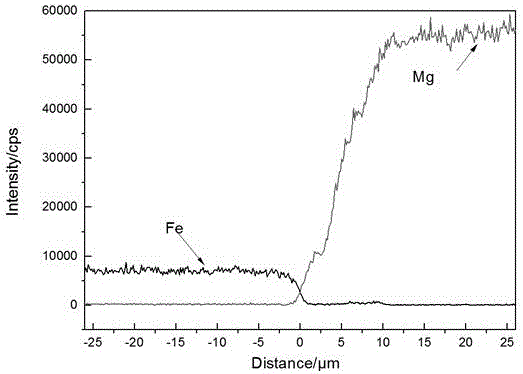

[0045] (3) Explosively weld the treated AZ31B magnesium alloy plate and 316L stainless steel plate: th...

specific Embodiment approach 3

[0050] (1) Select AZ31B magnesium alloy plate and 304 stainless steel plate as the base material for explosive welding; and anneal and toughen the AZ31B magnesium alloy plate, the annealing temperature is 300°C, and the holding time is 120min;

[0051] AZ31B magnesium alloy plate: 750mmX700mmX8mm;

[0052] 304 stainless steel plate: 800mmX750mmX3mm;

[0053] (2) Use mechanical grinding to remove the oxide layer and impurities on the interface between the AZ31B magnesium alloy plate and the 304 stainless steel plate to be bonded: that is, use an angle grinder equipped with a grinding wheel and a wire brush to initially grind the interface between the stainless steel and the magnesium alloy to be bonded, Then use 600-mesh sandpaper to polish, so that the roughness Ra of the surface to be bonded does not exceed 2 μm, and then wipe the surface to be bonded with a dry cloth.

[0054] (3) Explosively weld the processed AZ31B magnesium alloy plate and 304 stainless steel plate: that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com