Visualization testing method and device for granular material mechanics experiment

A granular material and mechanical experiment technology, applied in the field of granular material mechanical experiment visualization test method and its testing device, to achieve the effects of high precision, reliable use, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

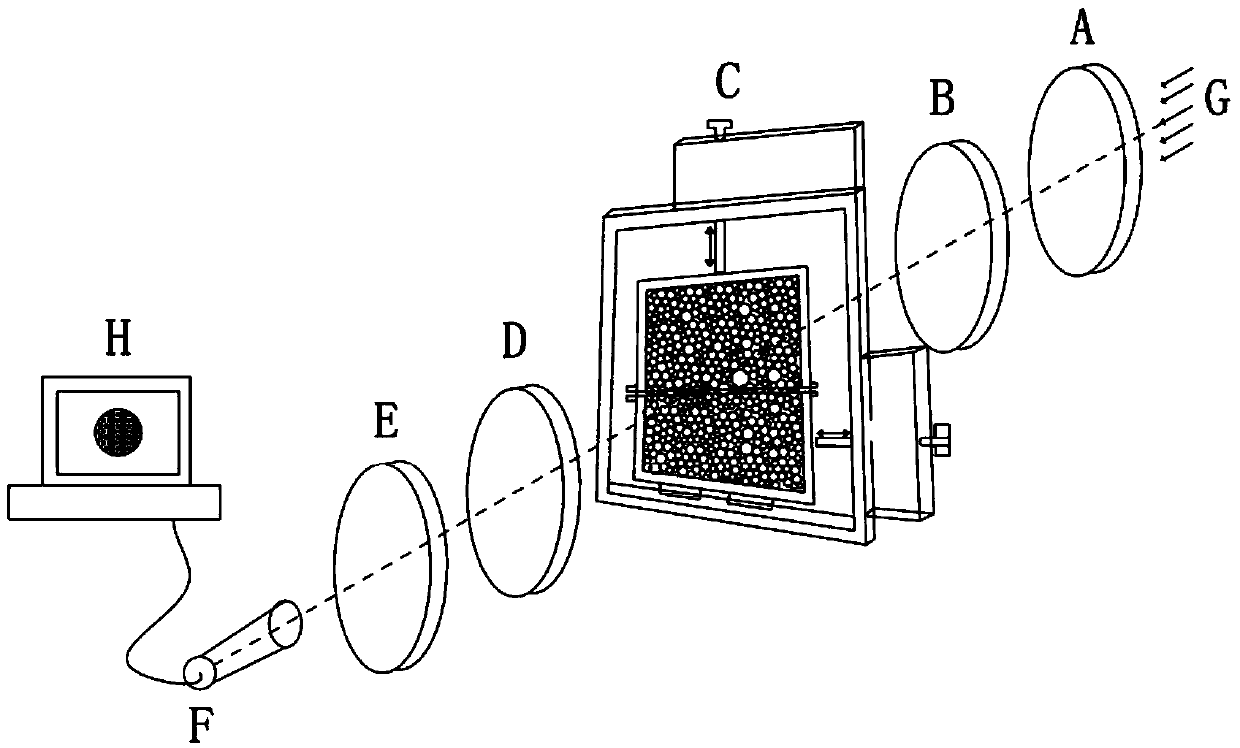

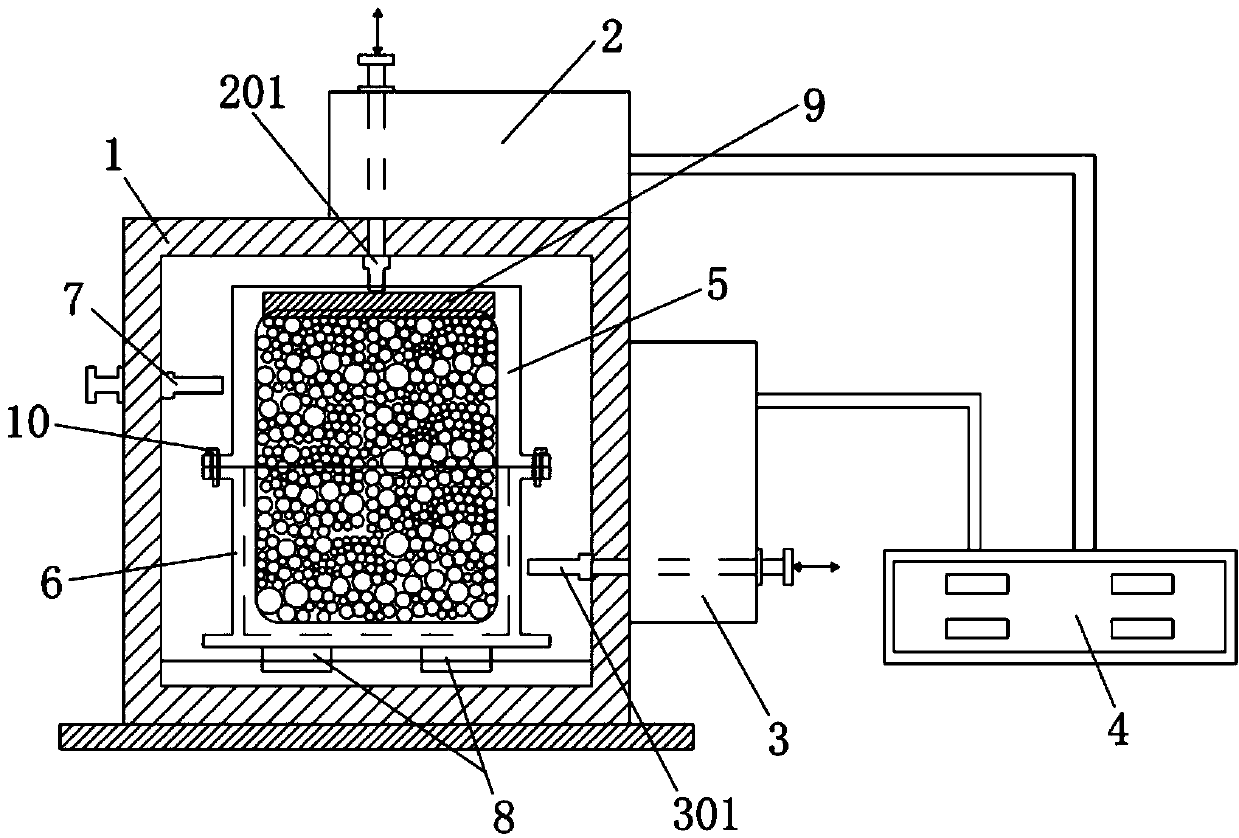

[0032] The method for visual testing of granular material mechanics experiments in the present invention is to first process millimeter-scale particles (the smallest size can be up to 2mm, its shape is spherical, cylindrical, elliptical cylindrical, polygonal or irregular), put it into the visual loading device that can apply compressive / shearing load, and then turn on the light source G, so that the light emitted by the light source goes along the Polarizer A, 1 / 4 wave plate B, visualization loading device C, 1 / 4 wave plate D, analyzer E, camera F spread, and ensure that the light emitted by light source G propagates to millimeter-sized particles, specifically as figure 1As shown, according to the corresponding experimental requirements (simulation of various common soil mechanics tests, such as compression, shear, stress arch, foundation load under rigid or flexible foundation, etc.), the millimeter-sized particles are subjected to compressive load or shear load, or The appl...

Embodiment 2

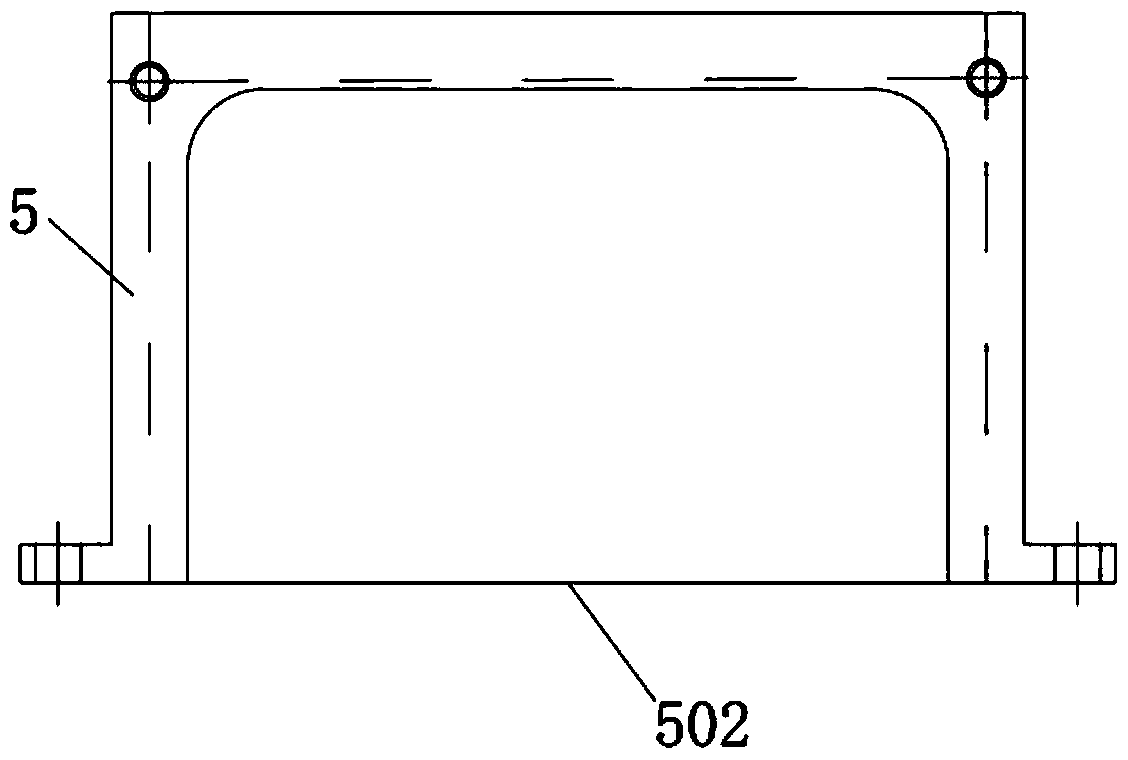

[0038] see Figure 7 As shown, what is different from Example 1 is that this embodiment puts two rectangular steel plates 11, 12 in the described granular material sample box (the rectangular steel plates can be selected from various sizes, and the distance between the two steel plates depends on The size of the steel plate is adjusted) to simulate a fixed pile. Then fill up the granular material around the steel plate, the granular material is determined according to the selected slot spacing, and also put the granular material of the corresponding length from the top discharge port of the granular material sample box 5 on the visualization, in this implementation The granular material used in the example is also a photoelastic cylinder with a diameter of millimeters. Similarly, a large number of small cylinders are put into the granular material sample box with slender tweezers. Close to the wall of the visualization board, when the sample box of the granular material is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com