High-yield-strength oriented silicon steel shearing process

A technology of grain-oriented silicon steel and yield strength, which is applied in the field of high-yield-strength grain-oriented silicon steel shearing technology, and can solve the problems of different ranges of edge trimming control of grain-oriented silicon steel products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

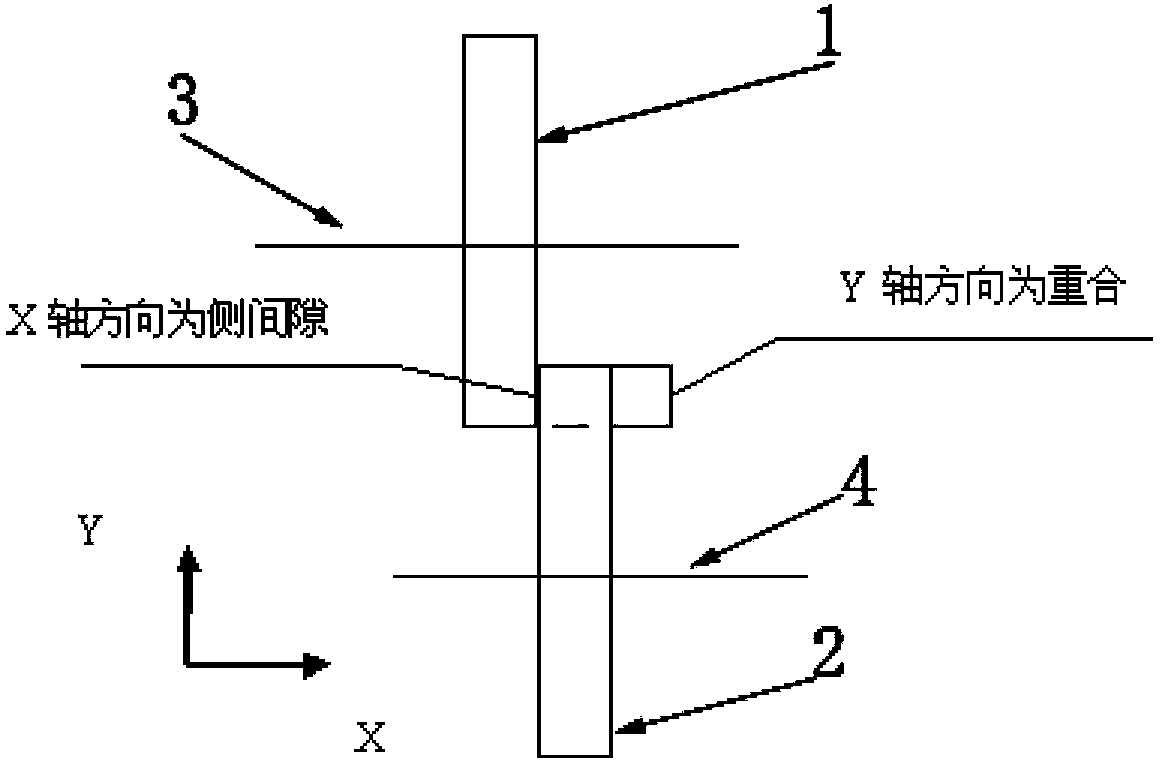

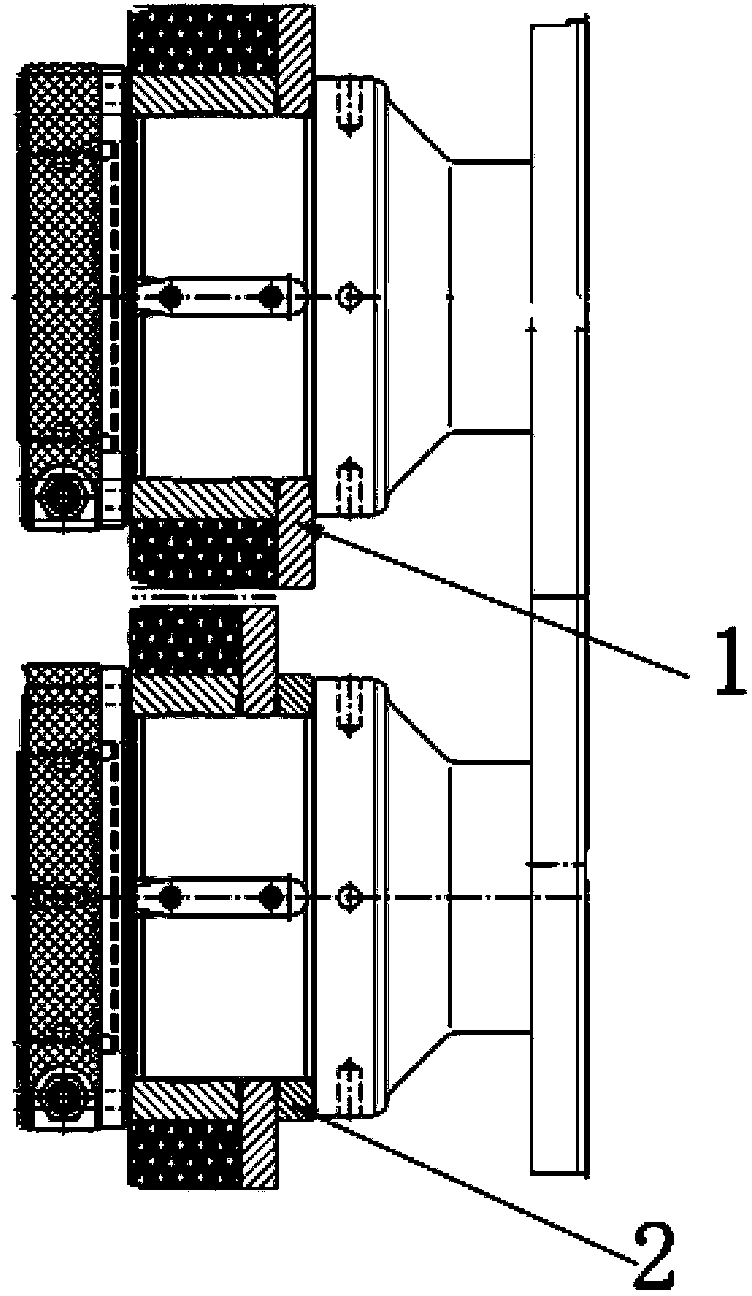

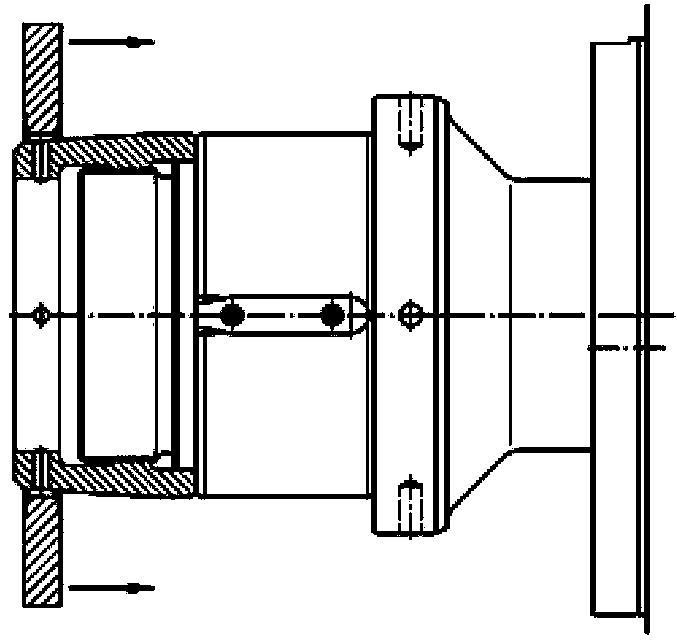

[0127] The invention is a method for controlling the edge trimming quality of oriented silicon steel products, which is mainly realized through the following methods:

[0128] 4.1 Disc shear tension control method:

[0129] By reasonably adjusting the tension of the uncoiler and coiler, the stability of the strip in the shear area of the disc shear is controlled. Among them, the tension value range of the decoiler is 15N / mm 2 ±2, coiler tension value range 17N / mm 2 ±2. In order to further stabilize the strip steel in the shear area of the disc shears, a pair of strip stabilizing devices are arranged before and after the disc shears. The device controls and adjusts the tightness of the strip steel through the lifting and lowering of the upper stabilizing roller, and changes the wrapping angle of the strip steel rollers, thereby stabilizing the strip steel well.

[0130] The tension control of uncoiler and coiler has been included in the CP control of Q172 unit.

[0131...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com