Fuzzy PID control method and execution apparatus of numerical control machine

A control method and technology of CNC machine tools, applied in the direction of digital control, adaptive control, electrical program control, etc., can solve the problems of intelligent control technology that is far from being popularized, unable to eliminate steady-state errors, and poor static performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings.

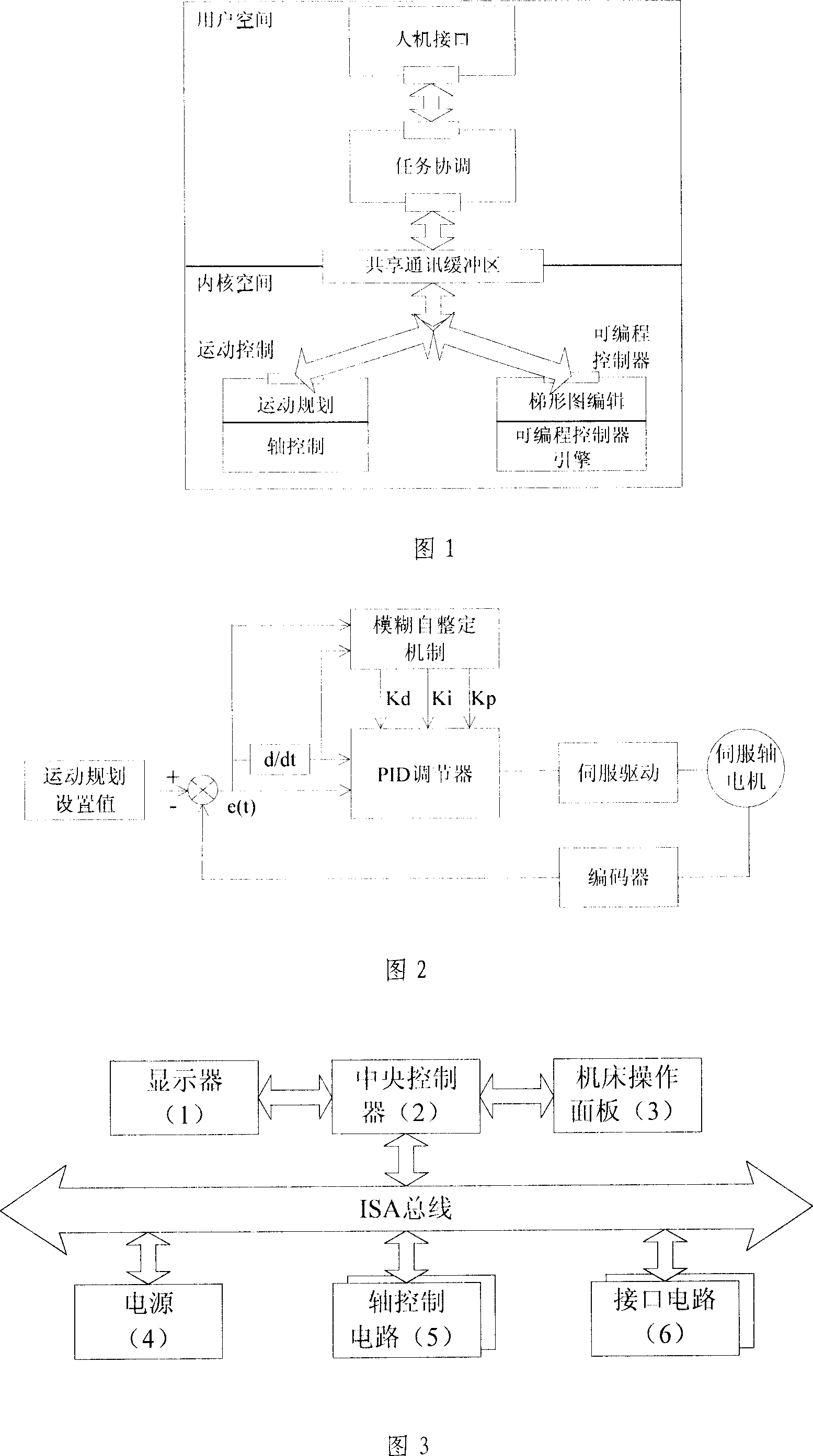

[0053] (1) Fuzzy PID control method of CNC machine tools

[0054] Referring to Figure 1, the human-machine interface, task coordination, motion control and programmable controller are used, and the motion control and programmable controller are loaded in the kernel space of the system, and the human-machine interface and task coordination part are loaded in the user space of the system. communicate with each other through the system's shared communication buffer; where:

[0055] The man-machine interface is used to accept operation commands and workpiece programs, to display the processing process of the implementation device of the present invention, and to realize the interaction between the machine tool operator and the implementation device of the present invention.

[0056] Task coordination consists of two parts: state management and artifact program i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com