Earth-structure interaction contact surface shearing test visualization device

A shear test, contact surface technology, applied in the direction of using a stable shear force to test the strength of materials, measuring devices, instruments, etc., can solve the in-situ test of only a few mm or 1-2cm, which cannot be loaded, unloaded and transported. , large-scale testing machines and other problems, to ensure stability, high reliability of test results, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

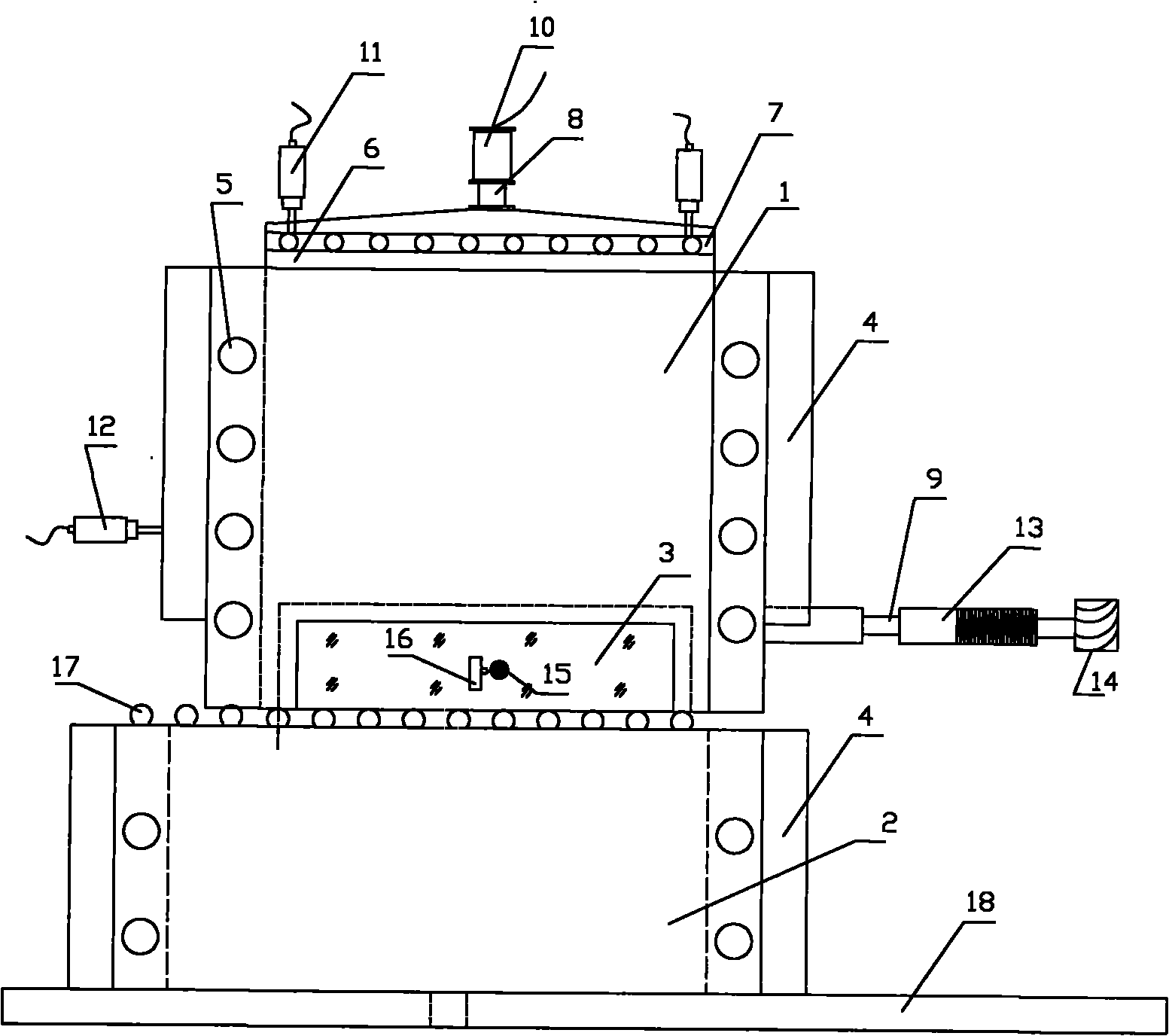

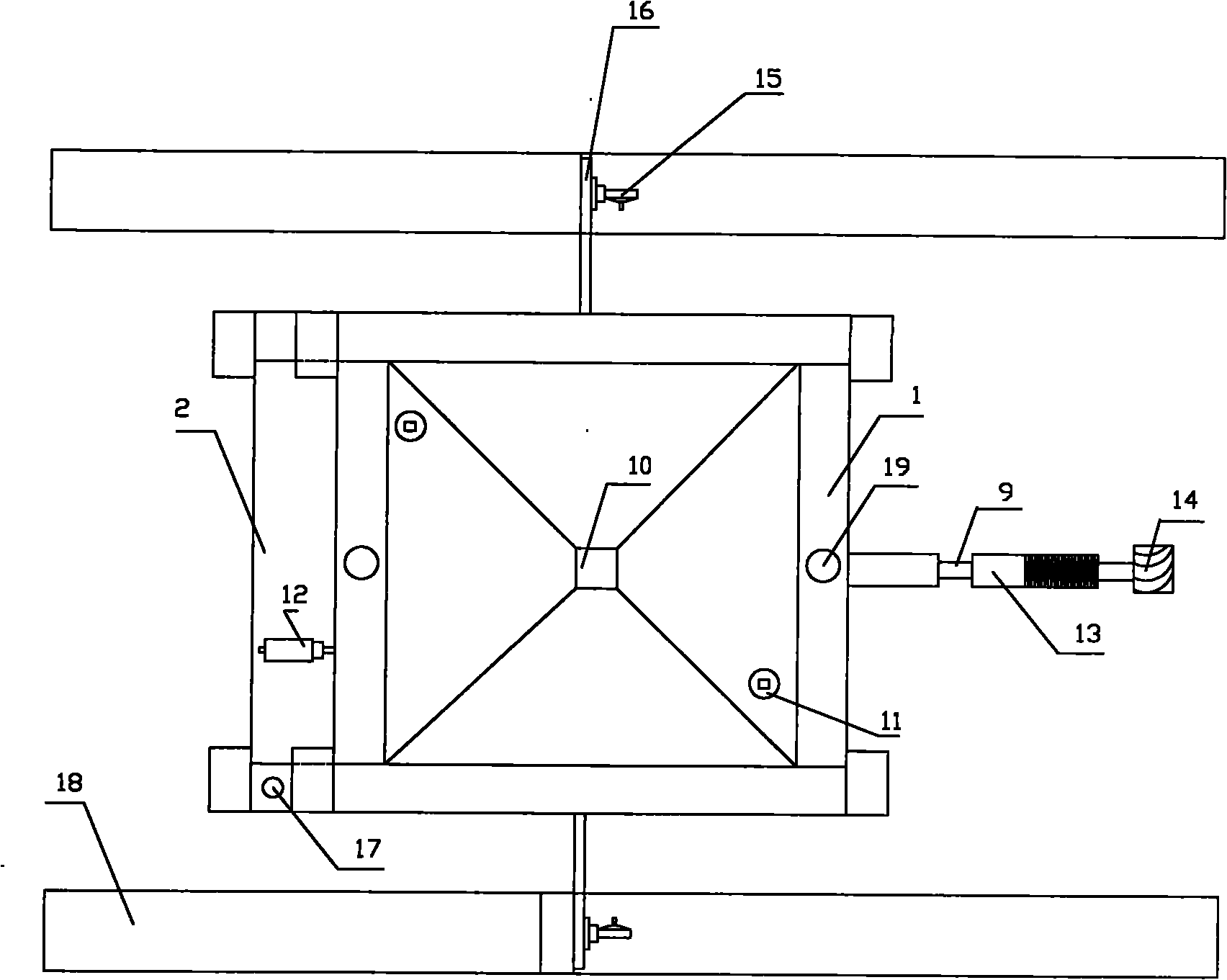

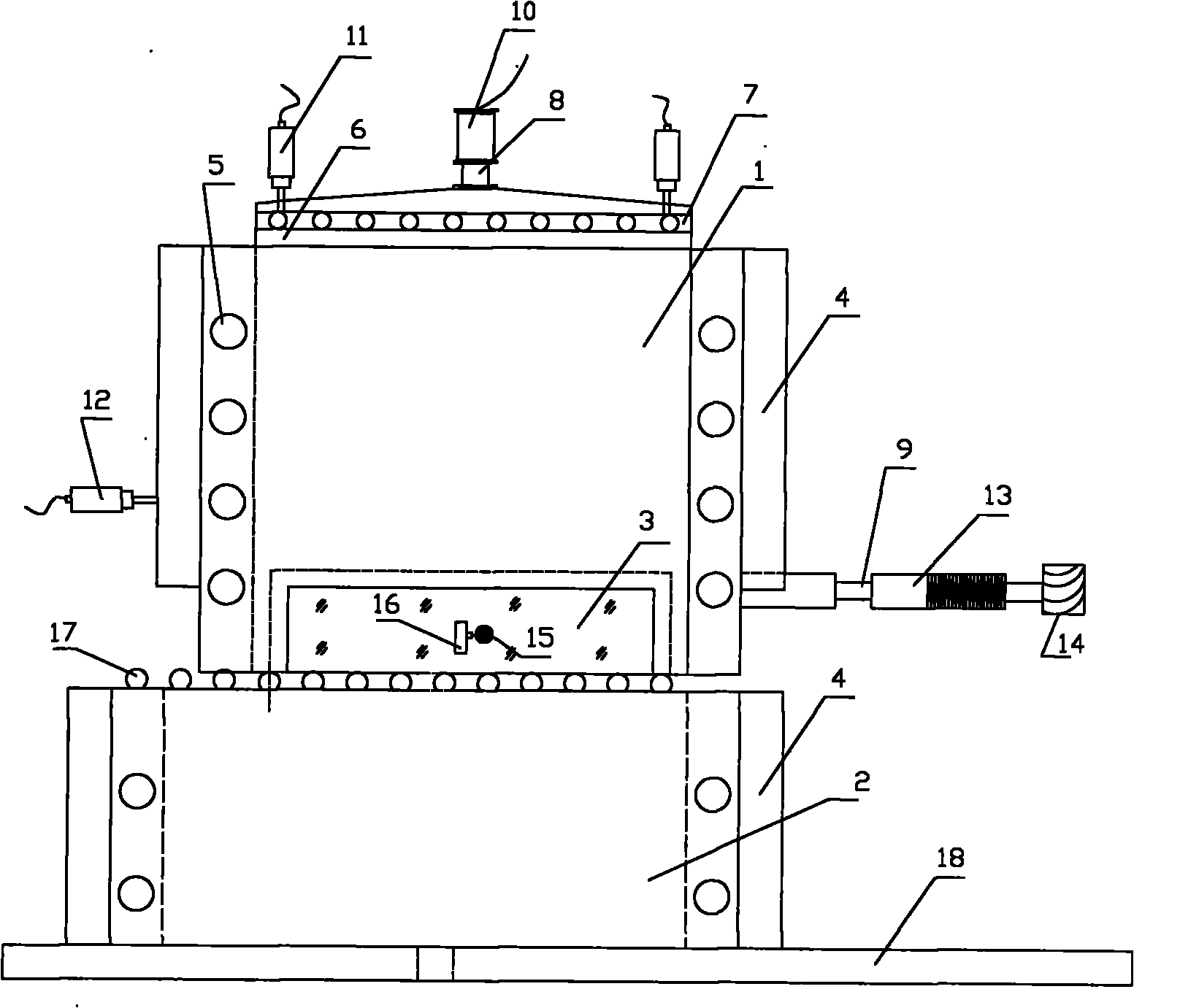

[0011] The present invention will be further described in detail with reference to the accompanying drawings for the interface shear test visualization device for interaction between soil and structure.

[0012] Referring to the accompanying drawings, the shear test device of the present invention consists of an outer frame 18, a horizontal and vertical loading system, a shear test visualization device, and a measurement system. The basic structure of the shear test visualization device mainly includes upper shear box 1, lower shear box 2, perspective window 3, reinforced steel plate 4, steel bolt 5, camera device 15, connecting seat 16, ball row 17; horizontal and vertical loading The system includes a square pressure bearing plate 6, a roller row 7, a jack 10, a horizontal thrust rod 13, a motor 14, and eyelet holes 19; the measuring system includes a vertical load sensor 8, a horizontal load sensor 9, a vertical displacement sensor 11, and a horizontal displacement sensor 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com