Hoisting Hoses and Handling Equipment

A technology for operating equipment, hoses, applied in the direction of transportation and packaging, load hanging elements, chucks, etc., which can solve the problems that cannot be easily reduced, and achieve the effect of small local stress and high shear movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the figures and in the following description, the same reference symbols are used in each case for identical or mutually corresponding features.

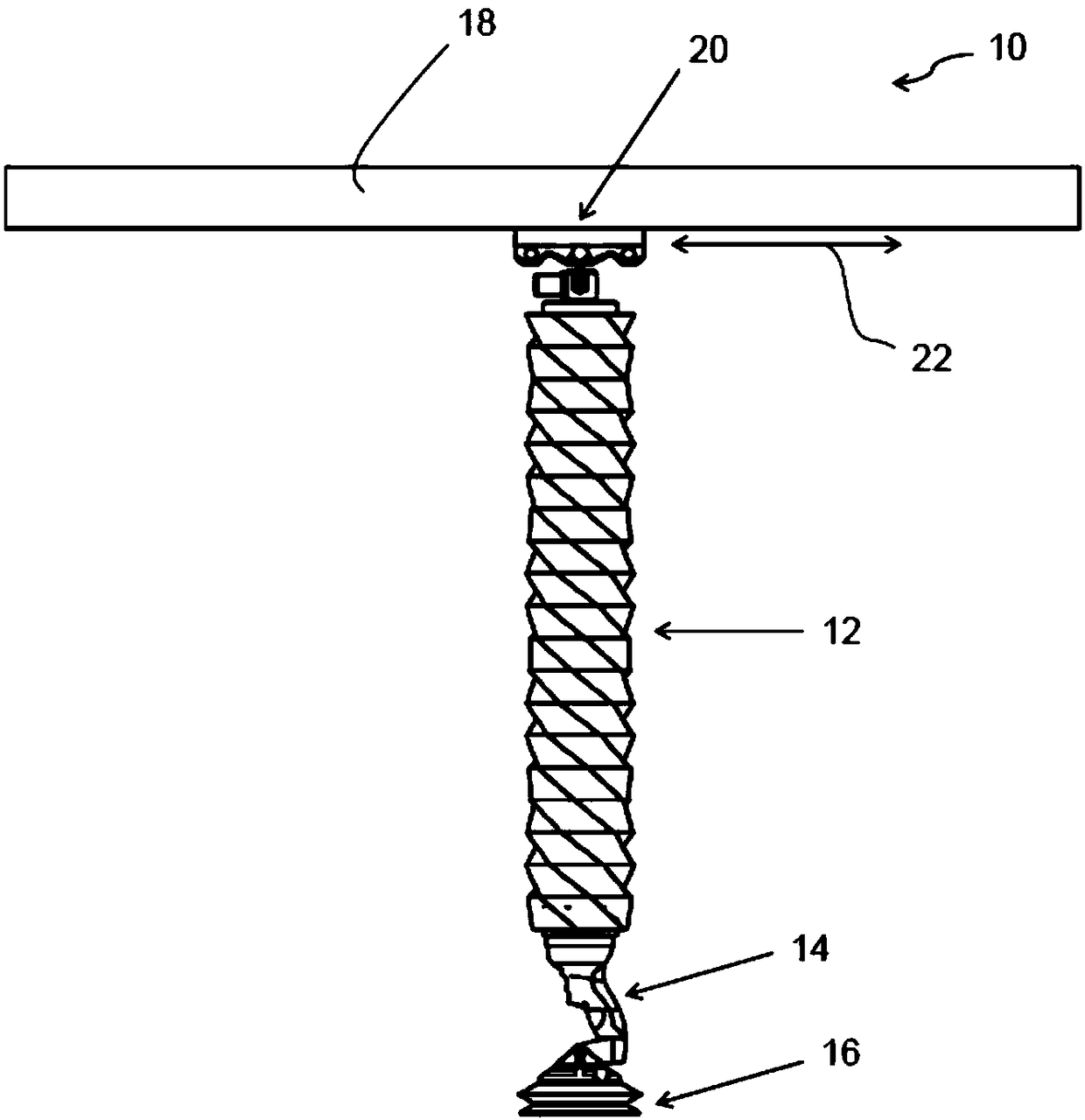

[0033] figure 1 An overview of a hose lifter 10 is shown with a lifting hose 12 described below, wherein the end of the lifting hose 12 is coupled via a handling device 14 to a suction gripping device 16 . The lifting hose 12 is connected with its end opposite the suction gripping device 16 to the support body 18 , in particular the suspension point 20 of the lifting hose 12 is displaceable in a transverse direction 22 .

[0034] Objects to be gripped (not shown) can be sucked by means of the vacuum gripping device 16 . By suitable actuation of the operating device 14 , the lifting hose 12 can be shortened by applying a negative pressure to its hose interior (see below) and thus the grasped object can be lifted.

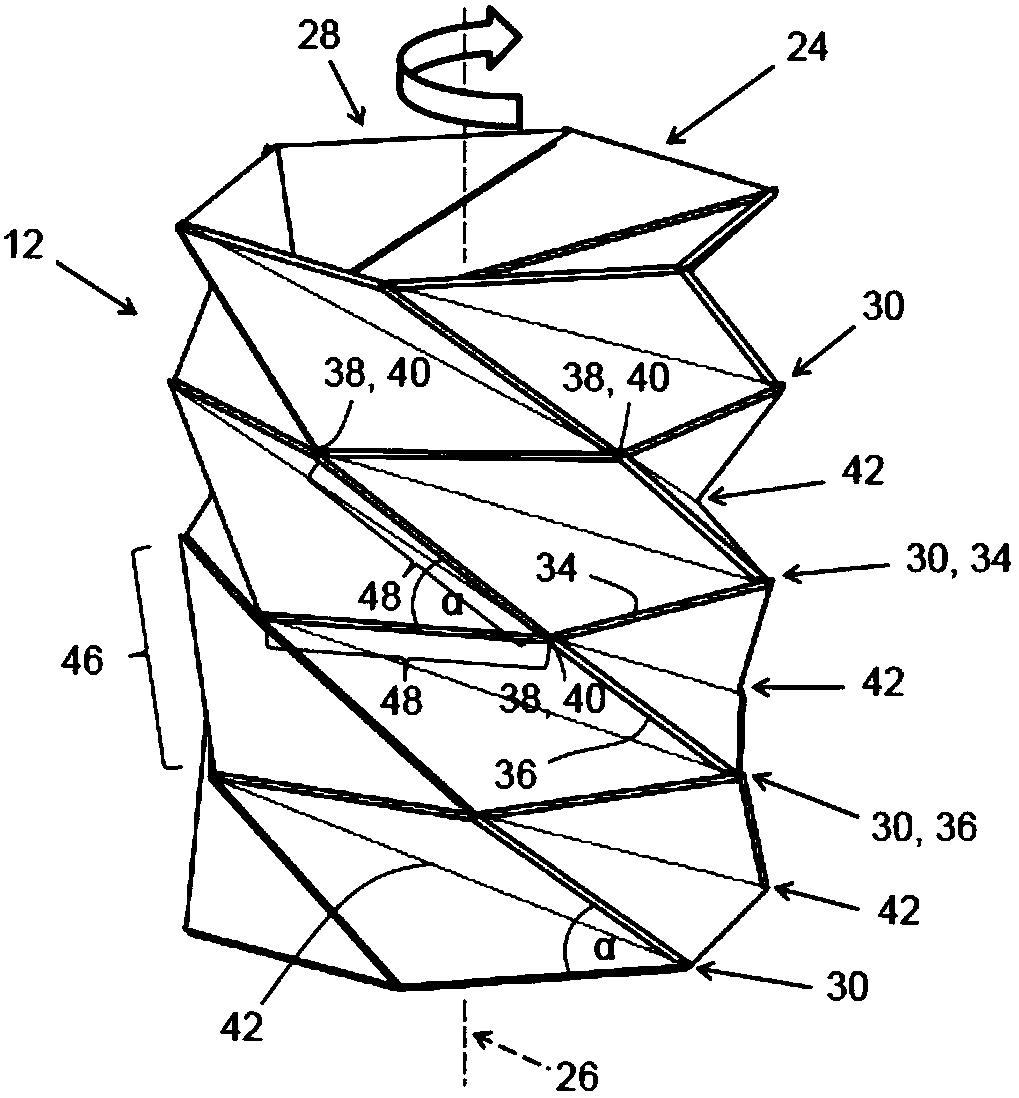

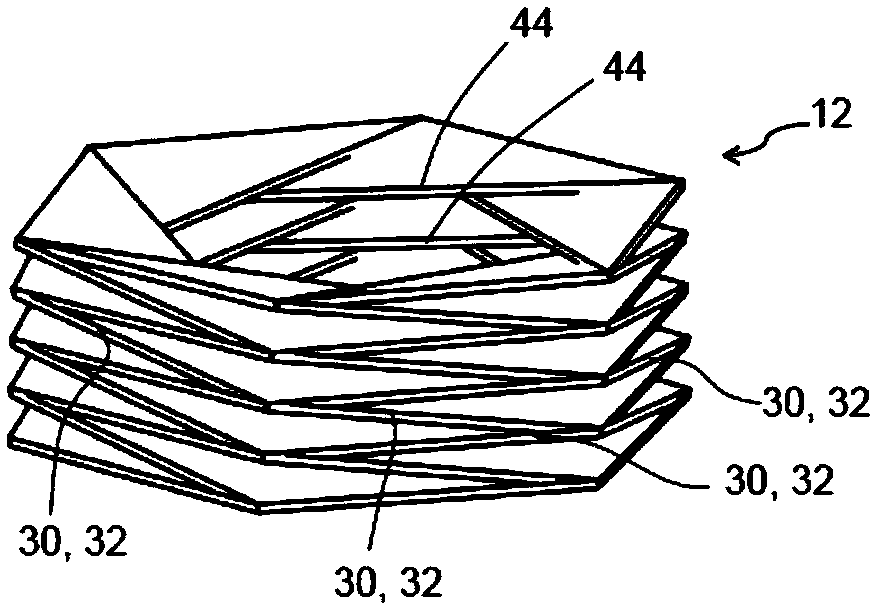

[0035] Figure 2 to Figure 5 Different views and different configurations of sections of the lifting hose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com